Product

Contact Us

Silicon Carbide (SIC) Ceramic Membrane

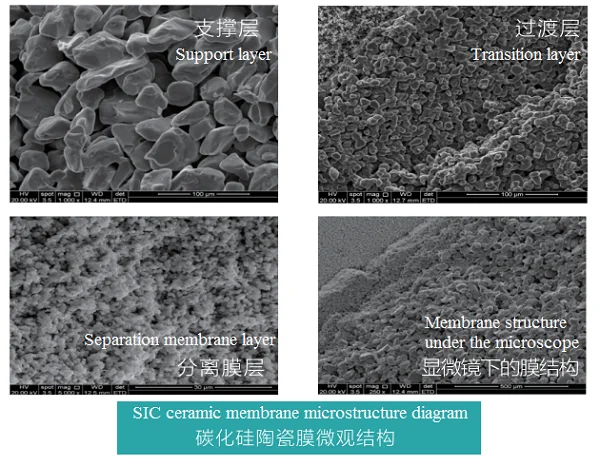

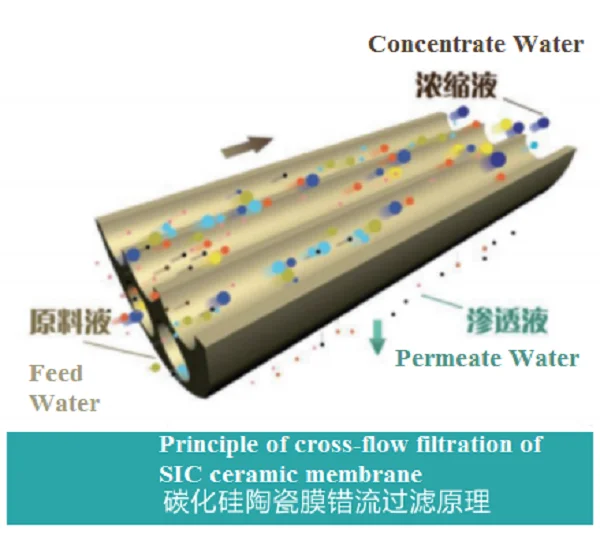

The silicon carbide ceramic membrane (SIC) is formed by high-temperature sintering by recrystallization technology, and the porous support layer, the transition layer and the membrane layer are all silicon carbide materials, and the filtration precision is microfiltration and ultrafiltration. The SIC membrane filtration system is a fluid separation process in the form of "cross-flow filtration". The raw material liquid flows at a high speed in the membrane tube, and the clarified permeate containing small molecular components is driven through the membrane dense layer in a direction perpendicular thereto. The turbid concentrate containing macromolecular components is trapped to achieve the purpose of clarification, separation, concentration and purification of the fluid.

The Features and advantages of silicon carbide ceramic membrane (SIC)

|

Properties |

Performance |

|

Material |

100% Silicon Carbide |

|

Membrane Structure |

Asymmetry |

|

Porosity |

> 45% |

|

Hardness |

2930+80 (Vickers hardness kg/mm2) |

|

Resistant Temperature |

Atmospheric Temperature 800 °C |

|

Resistant Chemical |

PH=0-14 |

|

Resistant chlorine Oxidant |

Any concentration |

|

Solvent |

Completely Stable |

|

Maximum Positive Transmembrane Pressure Difference |

3 Bar |

|

Maximum Negative Transmembrane Pressure Difference |

10 Bar |

SIC ceramic membrane application technology advantages

Good chemical stability, strong acid resistance, strong alkali, and all organic solvents

-- Strong acid, strong base, solid-liquid separation under strong corrosive conditions, and can be cleaned with any organic solvent, easy to clean, and the initial flux of the membrane can be recovered under any conditions;

Good thermal stability, thermal shock resistance

-- Stable operation under high temperature conditions;

The open porosity is high and the flux is large

-- Compared with the conventional tubular membrane, the equipment has high integration degree, small floor space, low energy consumption and small investment;

Good hydrophilic and oleophobic properties

-- Efficient separation of oil and water;

High membrane bonding strength and good wear resistance

-- Long service life

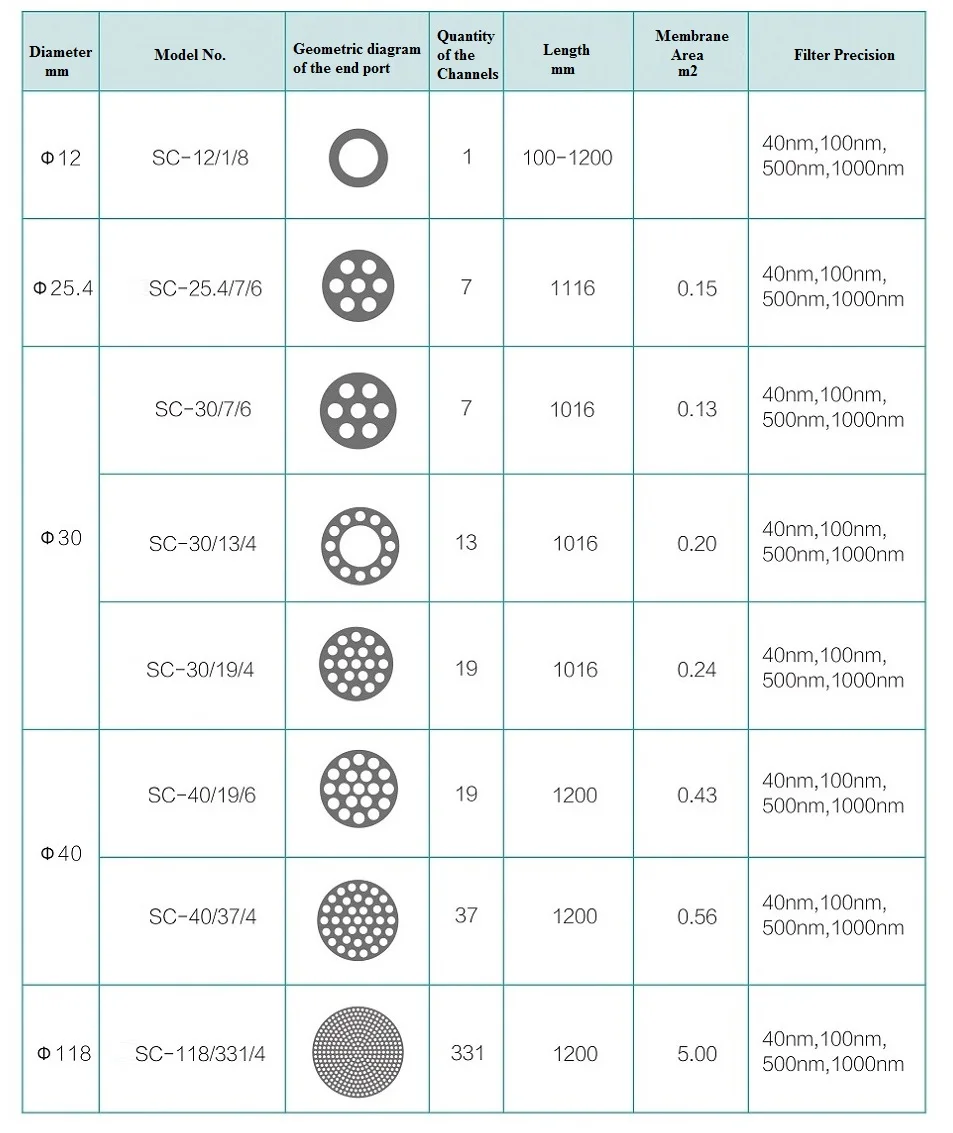

SIC Ceramic Membrane Model List

Ceramic Membrane Performance Comparison Table

|

Properties |

SIC Membrane |

UF Membrane |

Al2O3 Membrane |

|

Carrier Material |

100% SIC |

UPVC Material |

Al2O3 |

|

Filter Layer Material |

100% SIC |

PS\PVC\PAN\PVDF\PES |

Al2O3 |

|

Hardness |

High |

Low |

High |

|

Operating Pressure |

1-2 Bar |

1-2 Bar |

3-4 Bar |

|

Pure Water Flux |

3-4 m3/m2.h |

0.08-0.12 m3/m2.h |

0.25-0.5 m3/m2.h |

|

Resistant Temperature |

800 °C |

< 40°C |

<300°C |

|

(SIC)Silicon Carbide Ceramic Membrane |

||

|

SC-12/1/8 |

SC-25.4/7/6 |

|

|

SC-30/7/6 |

SC-30/13/4 |

SC-30/19/4 |

|

SC-40/19/6 |

SC-40/37/4 |

SC-118/331/4 |

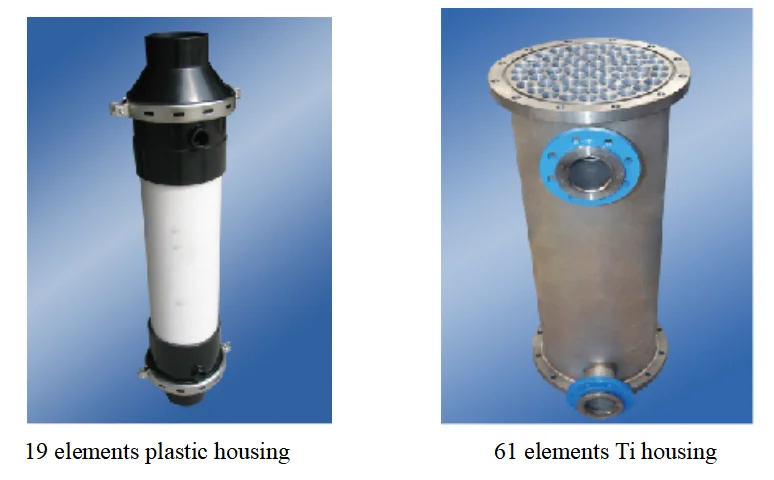

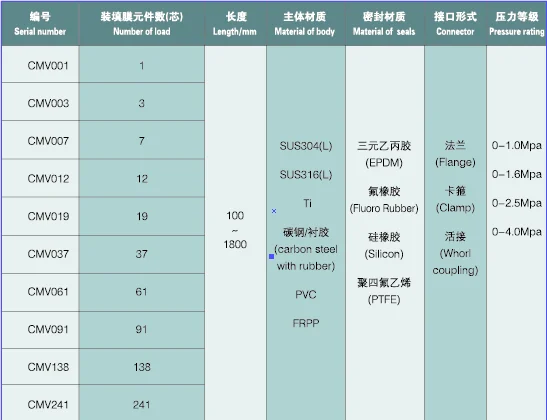

Membrane Housing

The company currently offers 1-element, 3-elements, 5-elements, 7-elements, 19-elements, 37-elements, 61-elements, 91-elements and 118 single-elements membrane housings. Customize the required membrane components according to customer needs and application scenarios. The materials are 304, 316, TI, PVC, FRPP.

The membrane module is a pressure resistant housing that is fitted with a ceramic membrane element. According to the needs of industrial production, centralized filling of ceramic membrane elements with different outer diameters and different areas can be realized by different module modules. The film area of a single membrane module varies from 0.02 m2 to 22 m2. The shape design and sealing design of the membrane module are essential for the operation of the ceramic membrane system.

Number of loaded membrane components: 1,3,7,12,19,37,61,76,91,138,241, etc.

Matching membrane element length diameter: 100 ~ 1800mm / outer diameter: 25, 30, 40mm

Body material: SUS304 (L), SUS316 (L), Ti, carbon steel with rubber, PVC, FRPP

Sealing material: EPDM, Fluoro Rubber, Silicone, Polytetrafluoroethylene (PTFE)

Interface form: flange (Flange), clamp (Clamp), joint (Whorl coupling)

Pressure rating: 0-1.0Mpa, 0-1.6Mpa, 0-2.5Mpa, 0-4.0Mpa

Standard: ISO, DIN / chemical grade, sanitary grade.