Product

Contact Us

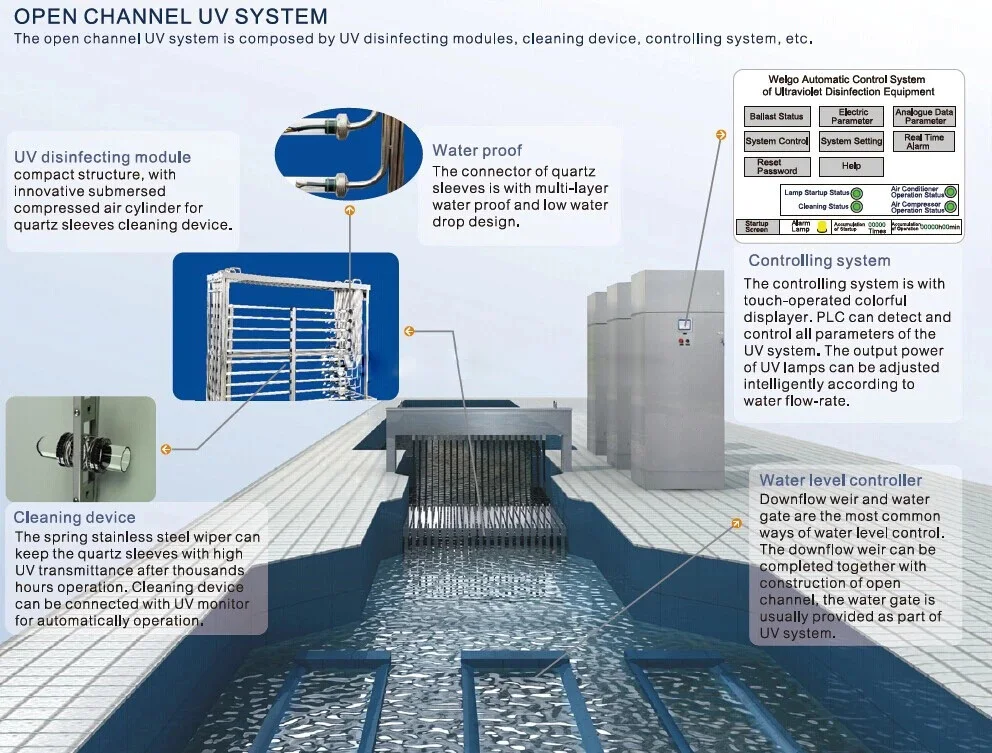

Open Channel UV System

Open-channel disinfection system

Mainly used for medium and large water disinfection projects, for example industrial and rain water recycling municipal sewage treatment plants.

The open channel UV sterilizer combines high-quality UV lamp technology with an automatic intensity monitor to ensure an effective hair growth dose and is equipped with a fully automatic wiper cleaning system.

Technical parameters

Capacity:500 M3/Day-100,000M3/day

Configuration: multiple modules in parallel

UV lamps: Europe/US imported 320W/lamp

System type: open-channel

Voltage: 110V/220V/380V/440V

Operating pressure: 0.8Mpa

Disinfection rate: 99.99%

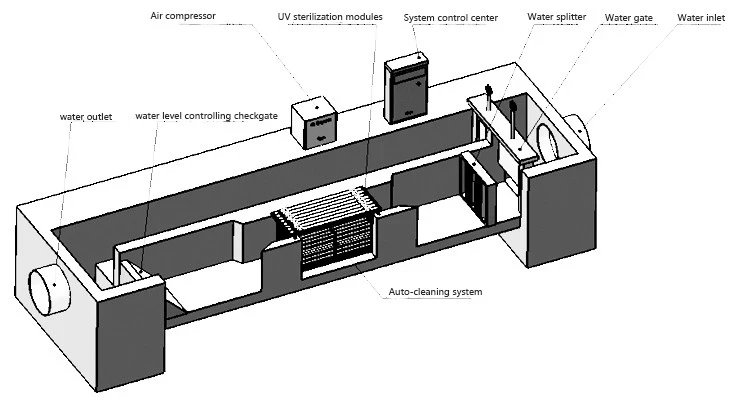

Structure of open channel UV sterilizer

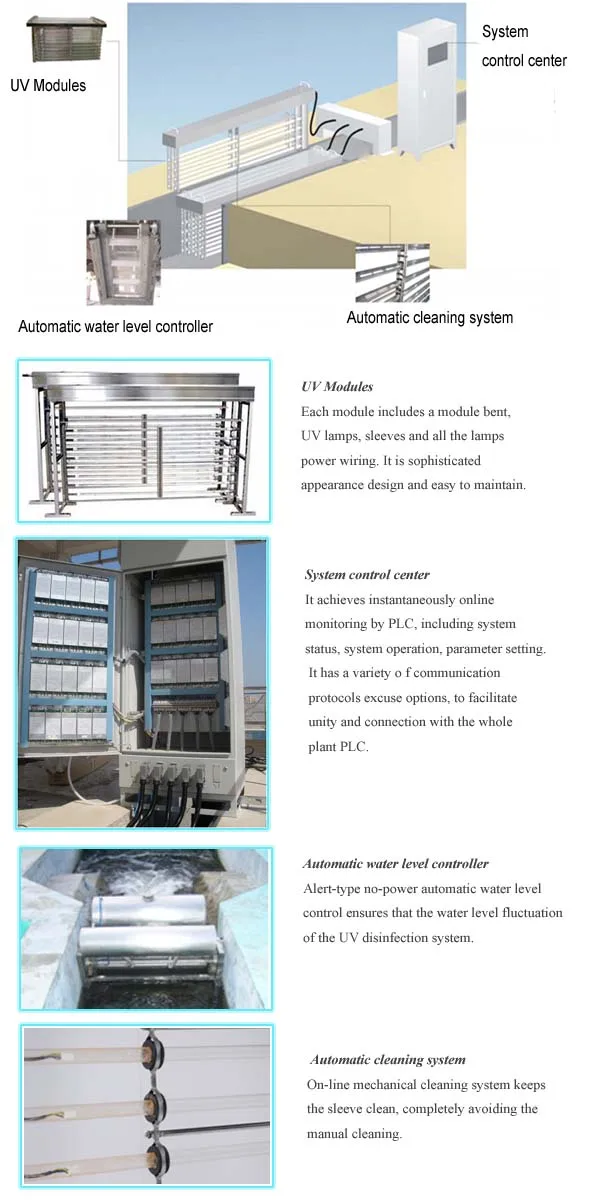

Open channel UV sterilizer includes: UV system module, automatic cleaning system, water level control, power supply system, power control center.

UV system module It is the core of the UV disinfection system, usually a single row of 8 UV lamps per row.

Key components of UV module: UV lamp tube, quartz sleeve, online automatic wiper cleaning system, power module, connector.

The modules are made of stainless steel;

the UV lamps are parallel to the water flow;

the module design is engineered to ensure leakage of UV radiation;

each module can be lifted when maintenance is required.

Power Control Center: Control the entire disinfection system, including electronic control center, interface input and output panel with power failure information, power transmission and distribution information, short circuit, overload protection functions; UV lamp status, cleaning status, UV intensity monitoring, running time recording and automatic cleaning function.

Power supply system (ballast power cabinet:) Provide power for UV module and control system: electronic ballast with cooling system to ensure sufficient service life and efficiency.

Water level control: water outlet channel or automatic water level controller to ensure that the UV module is under the water surface.

Automatic Cleaning System: The fully automatic cleaning system utilizes a wiper system to clean the quartz sleeve. The system has a PLC control system, which automatically controls the start, stop and interval setting of the cleaning system.

Open channel UV sterilizer Specification

| Model | Flow Rate(TPD) | Module Quantity(pcs) | 320W Lamp Quantity(pcs) | Module Total Power(kw) | System Total Power(kw) |

Dimension(mm) L*W*H |

| UV-320-8-2 | 5000 | 2 | 16 | 5.12 | 6.5 | 2100*200*1400 |

| UV-320-8-4 | 10000 | 4 | 32 | 10.24 | 12 | 2100*400*1400 |

| UV-320-8-6 | 15000 | 6 | 48 | 15.36 | 17 | 2100*600*1400 |

| UV-320-8-8 | 20000 | 8 | 64 | 20.48 | 22 | 2100*800*1400 |

| UV-320-8-10 | 25000 | 10 | 80 | 25.6 | 28 | 2100*1000*1400 |

| UV-320-8-12 | 30000 | 12 | 96 | 30.72 | 35 | 2100*1200*1400 |

| UV-320-8-14 | 35000 | 14 | 112 | 35.84 | 40 | 2100*1400*1400 |

| UV-320-8-16 | 40000 | 16 | 128 | 40.96 | 45 | 2100*1600*1400 |

| UV-320-8-20 | 50000 | 20 | 160 | 51.2 | 55 | 2100*2000*1400 |

| UV-320-8-24 | 60000 | 24 | 192 | 61.44 | 65 | 2100*2400*1400 |

| UV-320-8-28 | 70000 | 28 | 224 | 71.68 | 75 | 2100*2800*1400 |

| UV-320-8-32 | 80000 | 32 | 256 | 81.92 | 85 | 2100*3200*1400 |

| UV-320-8-36 | 90000 | 36 | 288 | 92.16 | 95 | 2100*3600*1400 |

| UV-320-8-40 | 100000 | 40 | 320 | 102.4 | 110 | 2100*4000*1400 |

| UV-320-8-44 | 110000 | 44 | 352 | 112.64 | 120 | 2100*4400*1400 |

| UV-320-8-48 | 120000 | 48 | 384 | 122.88 | 130 | 2100*4800*1400 |

| UV-320-8-52 | 130000 | 52 | 416 | 133.12 | 140 | 2100*5200*1400 |

| UV-320-8-56 | 140000 | 56 | 448 | 143.36 | 150 | 2100*5600*1400 |

| UV-320-8-60 | 150000 | 60 | 480 | 153.6 | 160 | 2100*6000*1400 |

| UV-320-8-64 | 160000 | 64 | 512 | 163.84 | 170 | 2100*6400*1400 |

| UV-320-8-68 | 170000 | 68 | 544 | 174.08 | 180 | 2100*6800*1400 |

| UV-320-8-72 | 180000 | 72 | 576 | 184.32 | 190 | 2100*7200*1400 |

| UV-320-8-76 | 190000 | 76 | 608 | 194.56 | 200 | 2100*7600*1400 |

| UV-320-8-80 | 200000 | 80 | 640 | 204.8 | 210 | 2100*8000*1400 |

Open channel UV sterilizer Application

UV disinfection systems are widely used in drainage, civil drinking water, hospital wastewater and reuse water projects

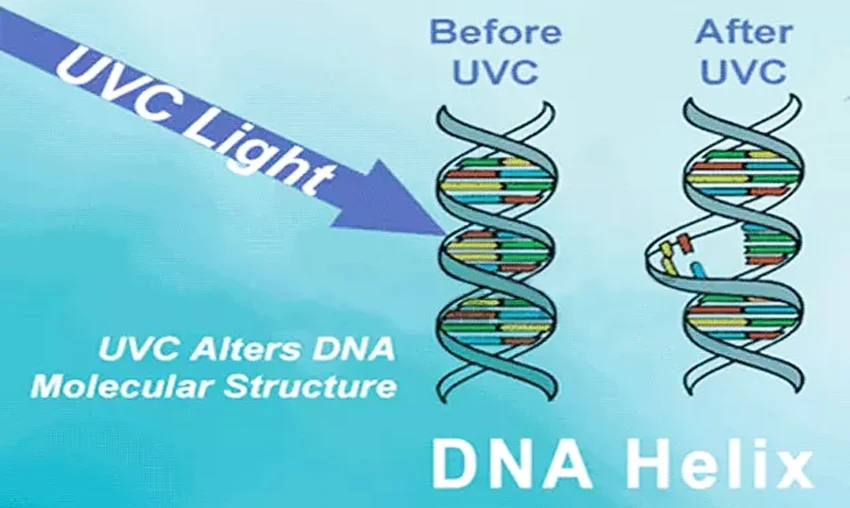

Working Theory Of UV Light Purification

UV Light Purification is invisible, exists in the outside of UV spectrum,so it is called UV radiation. According to a different wavelength range,they are cut into A, B, C three kinds of bands, including the C-band UV wavelength between 240-260nm, which is the most effective sterilizer band, band's strongest point it the wavelength of 253.7nm.

Open UV Sterilizer For Wastewater

It mainly consists of UV-C modules (horizontal type or vertical type as per process requirements), electronic ballast modules, central control module, self-cleaning (auto-mechanical) system, and level controller.

Low pressure high intensity UV-C lamps are used, high efficiency.

High quality lamps will be used, international brand, long lifetime (≥16000 hours).

The UV-C modules are made of material SS316L, above-water frames are made of SS304.

Each module can be lifted up independently, it is easy for maintenance, other modules will not be affected.

Advanced control/monitor system can automatically record UV lamp running time and monitor lamp on-off status, UV-C intensity, UV-C transmittance, water flow rate, it can also automatically adjust output power of UV-C lamp according to the signals of water flow rate and UV-C intensity.

Open UV sterilizer is tailor designed according to customer's process requirements.

Automatic self-cleaning reduces required maintenance cycles.

Exclusive atg UV Data stream service reduces required number of site visits.

Extended lamp life of 16,000 hours.

Improved health & safety – no open water sources, or risk of UV exposure.

Increased disinfection efficiency.

Increased electronic ballast life (new modern ballast design).

Reduced power consumption.

Significantly fewer lamps and quartz & ballasts.

Significantly reduced maintenance time.

Significant reduction in corrosion and structural damages.

Safety Warning

1.UV glasses must be worn for all the maintenance work

2.It is strictly prohibited to see ultraviolet lamp light with naked eyes in case that eyes hurt by ultraviolet light.

3.UV disinfection systems must have a good grounding to prevent electric shock accidents

4.Non-authorized electricians are not allowed to open the system control cabinet.

5.It is prohibited to change the configuration of the equipment’ modulator tube

6.Non-specialty staff or non-professional technical personnel is strictly prohibited to disassemble the equipment in the event of accidents.

7.Before working on maintenance, first cut off the main power supply

Product Show