Product

Contact Us

Screw Press

Description

The Screw Press introduced a new solution for sludge treatment with a new cutting-edge technology, streamline and automatic programmed design to make the operation much more convenient and accurate while provide a simple process, low system investment, high efficiency as well as energy -saving.

Our multi plate screw press is more advanced than traditional dewatering systems which can be easily blocked by low concentrated sludge. The Ecologix screw press allows for automatic continuous sludge flocculation, thickening, dewatering and filtrate discharging. The thickening zone allows the system to process both highly concentrated sludge as well as sludge with a high water content.

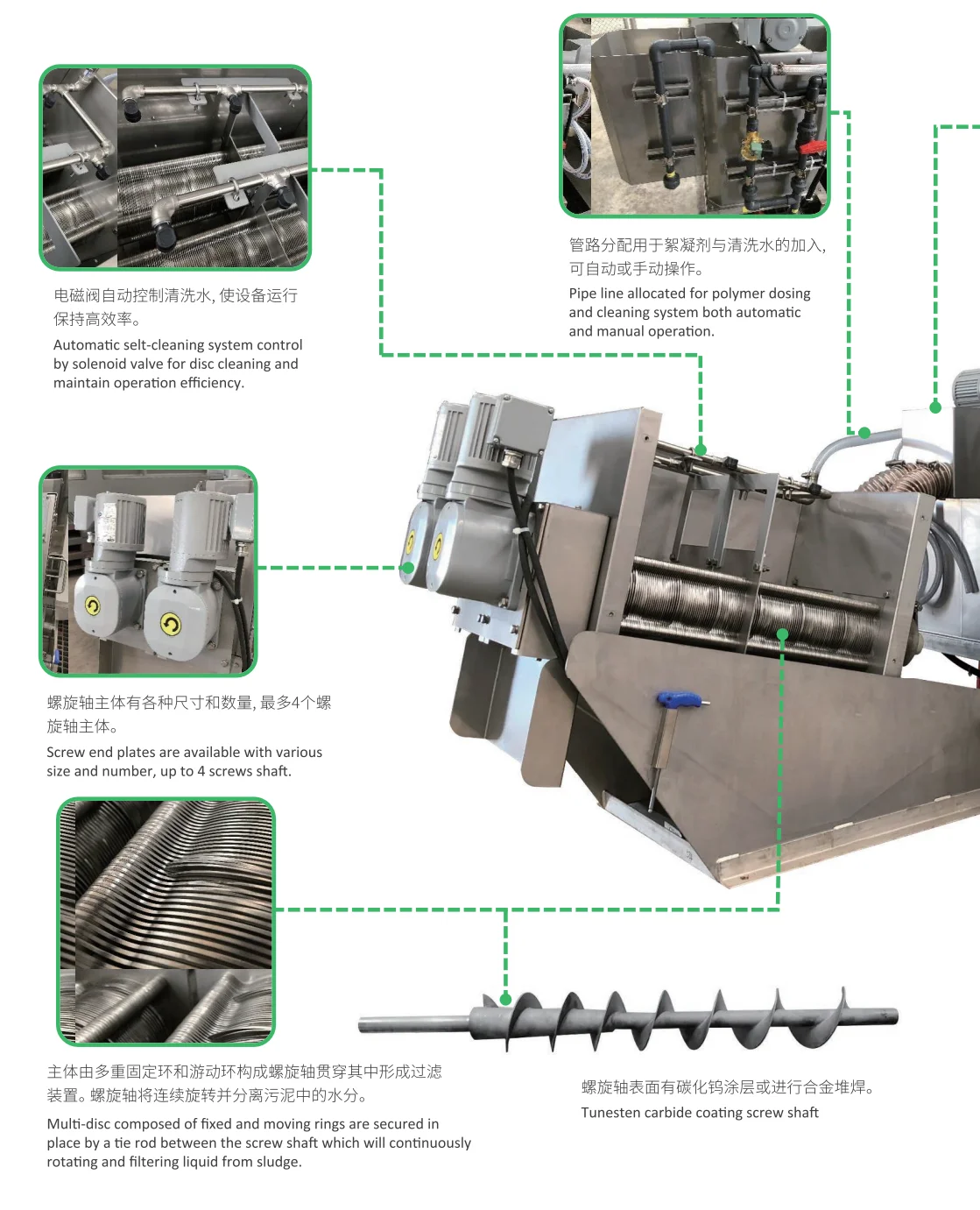

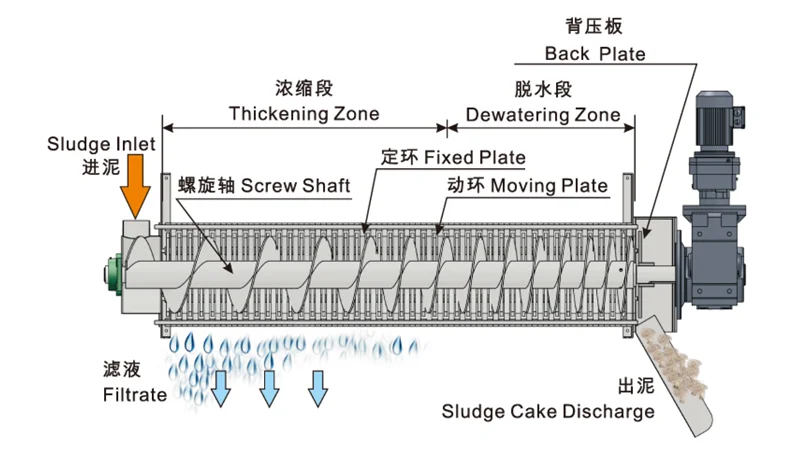

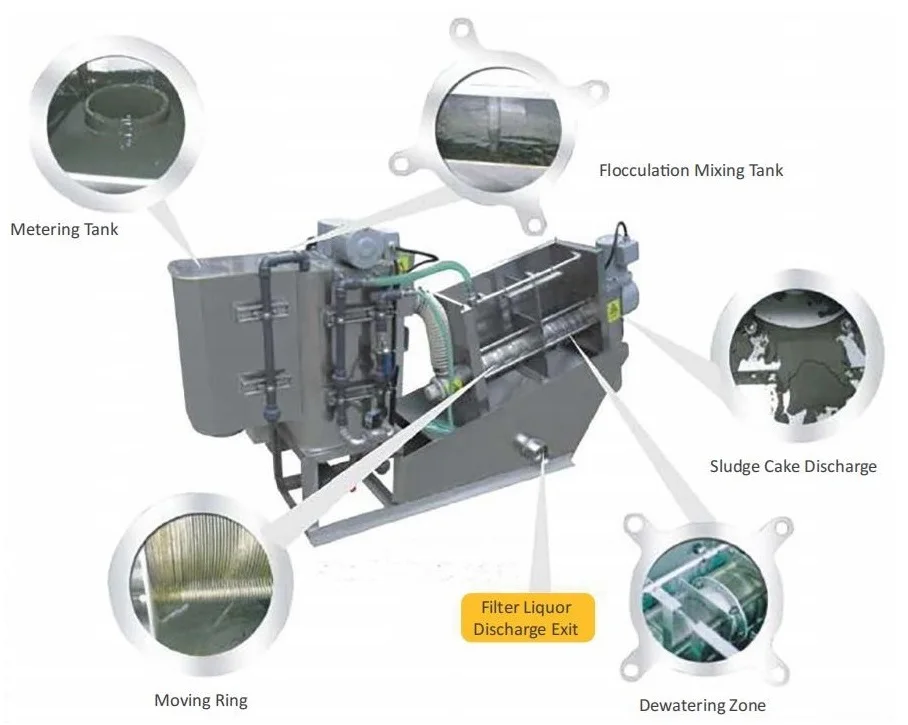

The core structure of the screw press is consisted of multiple layers of Fixed and Moving ring made by stainless steel sUS304 which secured in place by a tie rod while the inner diameters of the moving rings are relatively smaller than the outer diameter of screw and Fixed rings.

The traditional sludge treatment required a lots of pre-treatment process before the dewatering of sludge begin With the dewatering process can now be processed a low concentrated sludge from Oxidation ditch (aeration tank which provide the advantages in removing odor from sludge, reduce investment cost for Thickener tank and other related equipment as well as help in stabilizing the amount of phosphorus return into oxidation ditch which further implement a stable dewatering process.

Features

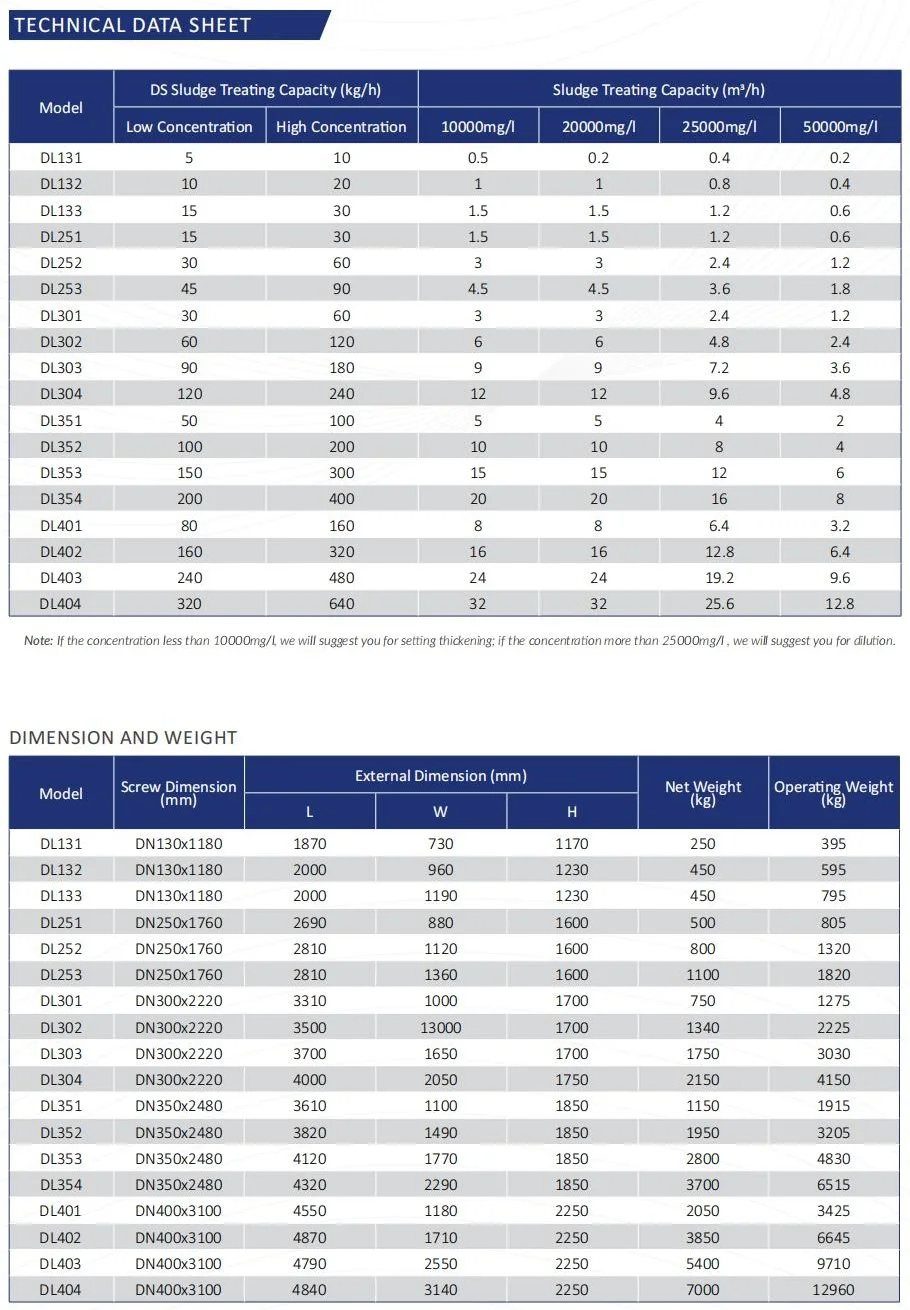

Exclusive pre-thickening enables a wide solid concentration ranging from 10,000mg/l to 50,000 mg/l

High efficiency with a small footprint

Low power consumption (less than 5% of a centrifuge)

Very low water usage (less than 1% of an equivalent belt filter press)

Auto start-up, run and shutdown

Self cleaning

No blocking or backwash water

Double nozzles for superior cleaning and rinsing

Able to handle oily sludge as well as fibrous sludge

Sealed system = No odors/bad smell

Wear free

Sludge flow and cake monitoring system

Exclusive screw shaft for sludge thickening and inorganic material

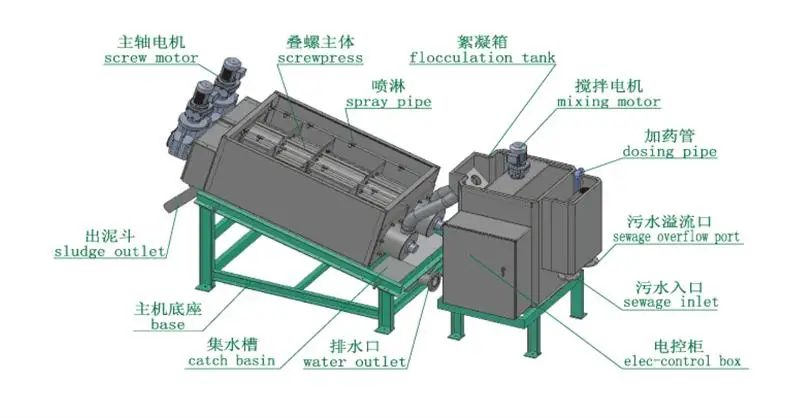

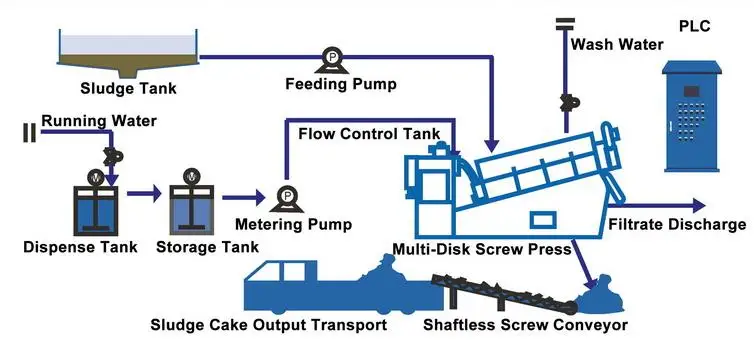

Multi Plate Screw Press Sludge Dewatering System

Components

304 SS Screw, Shaft, Collection Basin, Flocculation Tank, Main Body

Sludge thickening & dewatering zone

Sludge flocculation tank

Filtrate collection tank

Automatic / Automated control panel

Fixed plates and moving plates instead of filter cloth

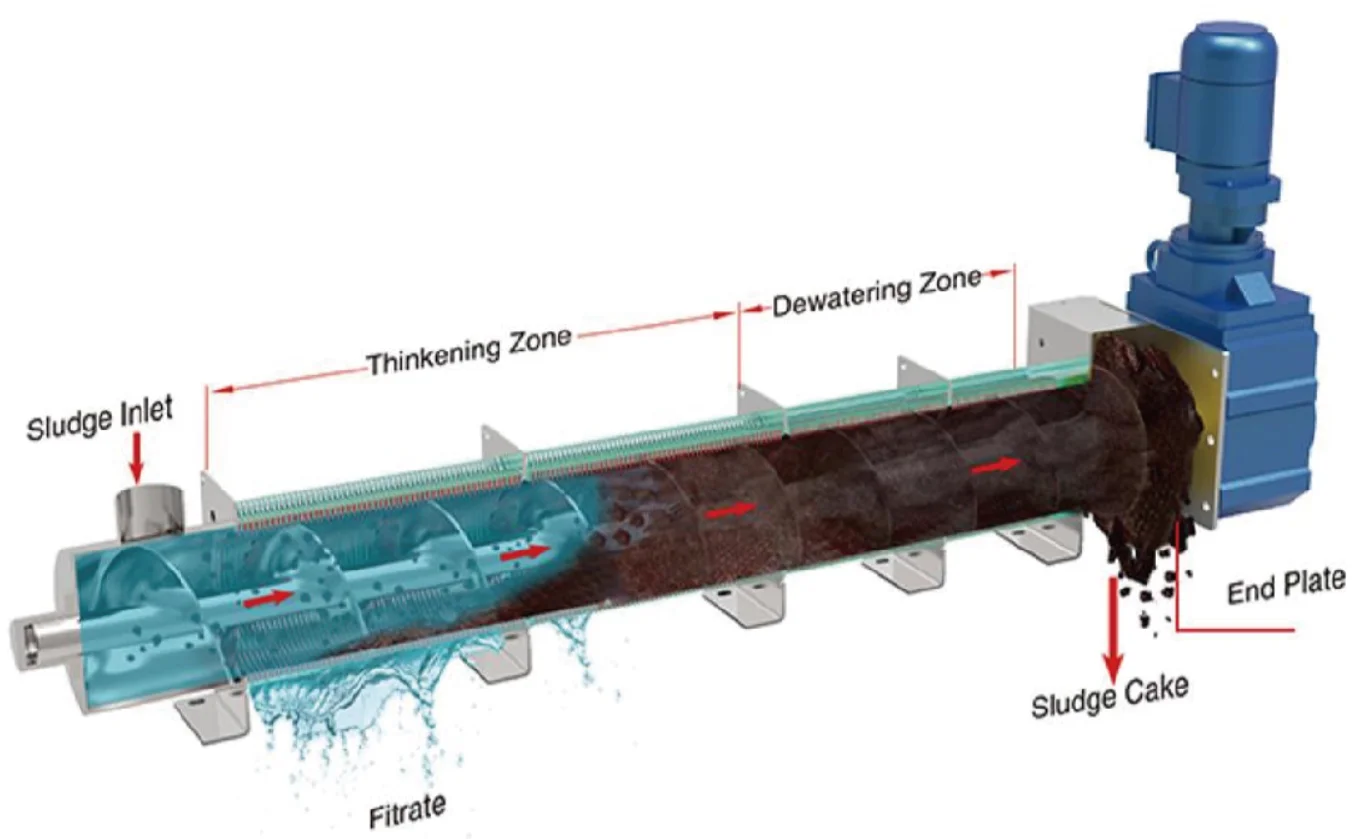

How It Works

The conditioned sludge flows into the filter chamber from the flocculation tank and is pushed to the discharging end. The thread on the shaft gets progessively tighter as the wasterwater flows through the system, this causes the pressure on the sludge to increase. The water is then separated from the sludge. The movement of the moving and fixed rings cleans the gaps between them and prevents blockage traditionally experienced in similar systems. The filtered sludge cakes are pushed forward by the shaft and finally discharged from the end.

Working Principle

The dewatering process begin at the initial section called Thickening zone, when the screw shaft rotating and separating liquid from solid sludge by the gaps between the multi-disc rings, the filtrated will then be discharge at the bottom drain hole while sludge will moving on to Dewatering zone where the pitch of the screw and the gaps between the multi-rings decrease at the end of drum thus increasing internal pressure at the end plate to discharge dry sludge cake.

The structure of Fixed and moving rings provided a clog-free feature in which the moving rings are mobilizing by the screw and continuously cleans the sludge out of the gaps to prevent clogging.

Advantages

Widely used in many industries sludge treatment including municipal sewage, food, slaughtering breeding printing dyeing oil chemical, paper industry, leather; pharmaceutical, etc.

Oily sludge handling capability.

Ability to handling low concentration sludge from 2,000 mg/L up to50,000m g/L.

Rotating ring and automatic spray cleaning system provide selfcleaning ability during process and prevent clogging allowing a continue operation for 24 hour without user assist.

Control panel equipped with inverters and pic for automatic and manual function.

Wear free structure, long service life and utilizing a small footprint for installation.

Type description

Cost efficiency

With innovation and working principle of screw press allowing it to leverage a cost efficiency in energy consumption for wastewater treatment system, due to its low speed running(2-4 rpm) while operating, provide screw press to consume energy at low rate (average energy consumption at 0.1-0, 01 kwh/kg-DS.,low water consumption for cleaning as well as generate minimum noise.

By using multi-disc technology the sludge can be draw directly from aeration tank and secondary sedimentation tank without establishing a sludge thickeners process, thus, enhancing phosphorus removal effect in wastewater treatment system as well as deceasing a total investment cost as a whole.

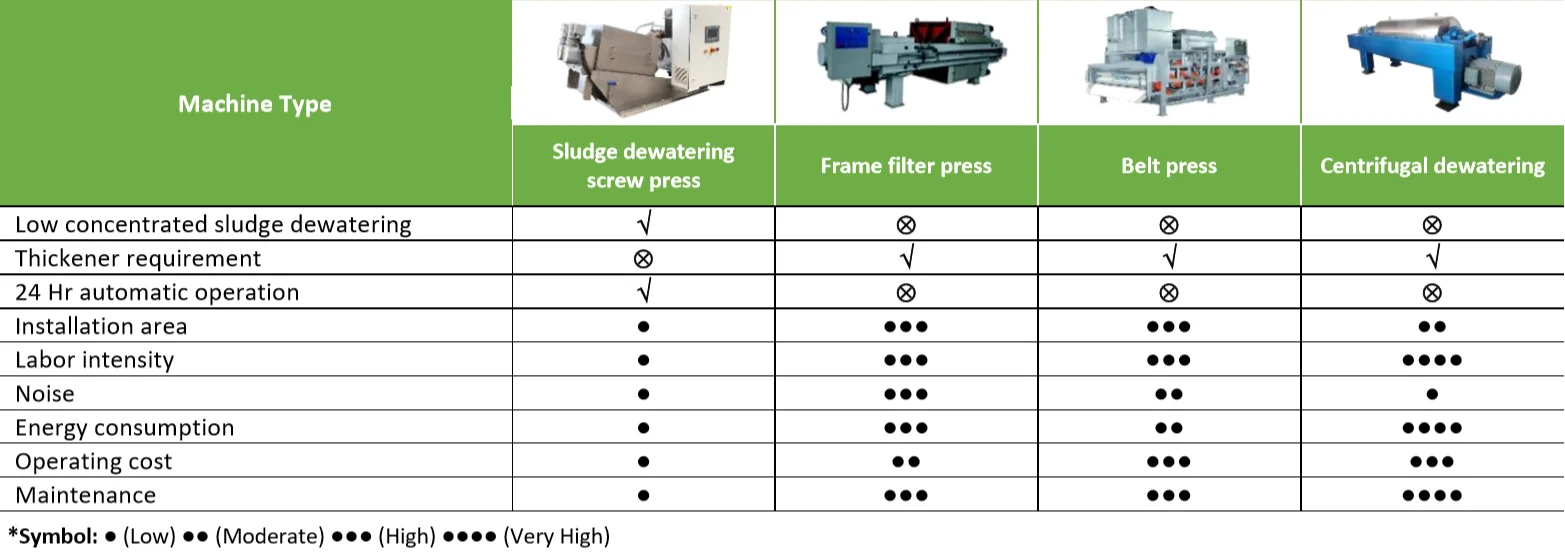

Comparison Chart

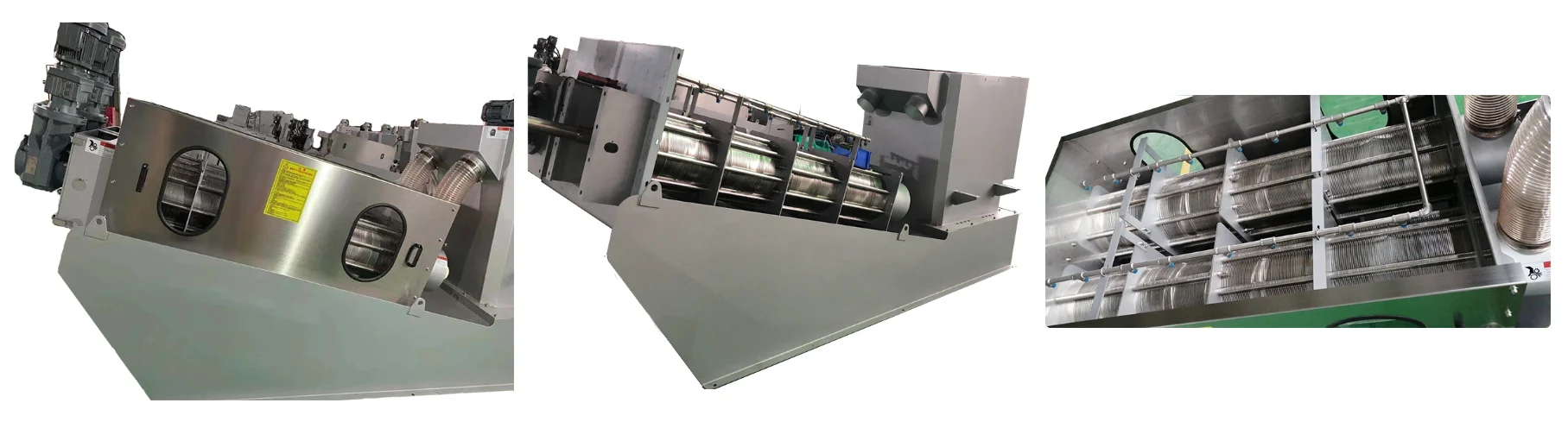

Product Show