Product

Contact Us

Hollow Fiber MBR Membrane Bioreactor

Membrane Bioreactor (MBR) is a new type of wastewater treatment technology that combines high-efficiency membrane separation technology with biochemical technology. The hollow fiber membrane module directly performs solid-liquid separation in the biochemical pool, replacing the secondary sedimentation tank in the activated sludge method, and effectively achieves the purpose of muddy water separation. The high-efficiency retention effect of the membrane allows the nitrifying bacteria to be completely retained in the bioreactor, so that the nitrification reaction can be smoothly carried out, the ammonia nitrogen can be effectively removed, the sludge can be avoided, and the macromolecular organic matter which is difficult to degrade can be retained at the same time, and the The residence time of the reactor is maximized. After applying MBR technology, the main pollution removal rate can reach: COD≥93%, the suspended solids and turbidity are close to zero, the water quality is good and stable, and it can be directly reused to realize the sewage resource.

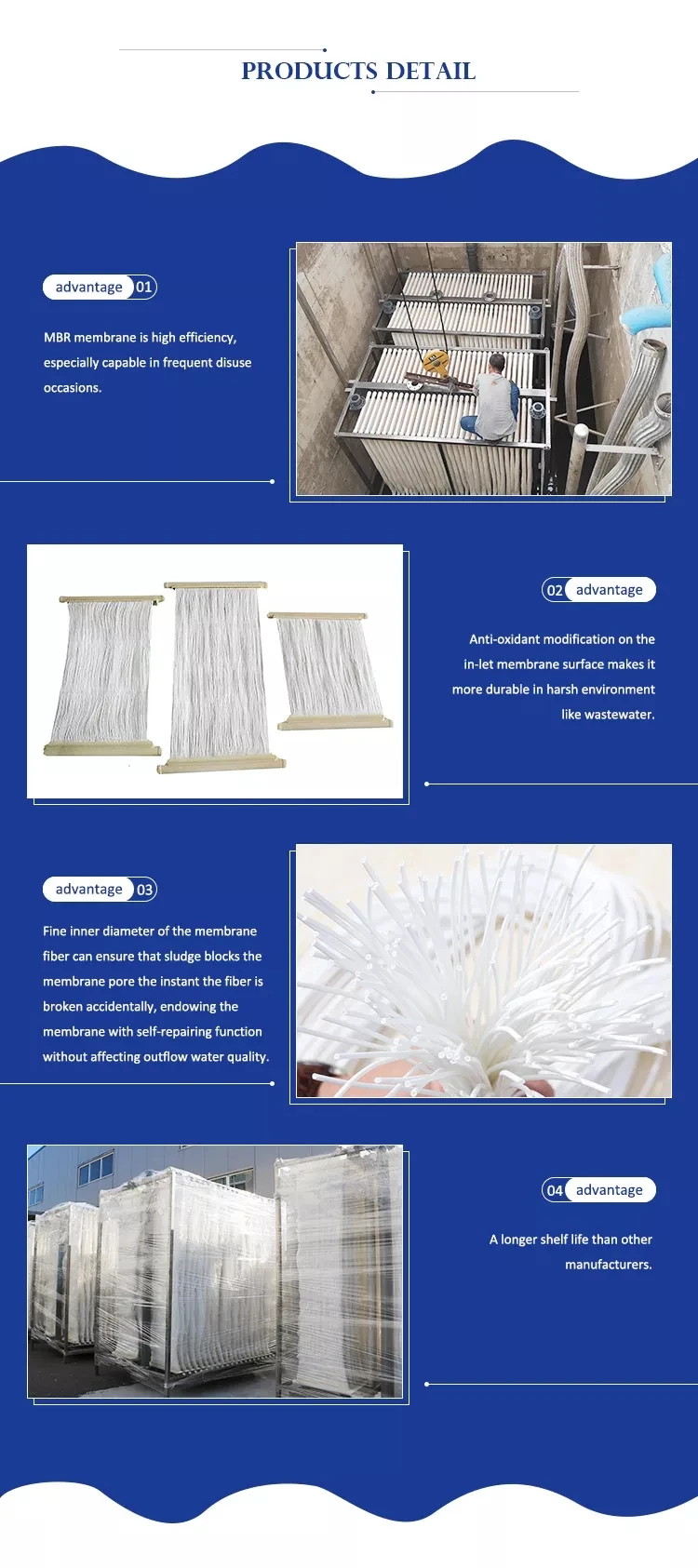

Hollow Fiber MBR Advantages

1.High strength:

Reinforced composite PVDF hollow fiber membrane adopts unique support layer membrane technology, which makes its tensile strength and compressive strength much higher than ordinary hollow fiber membrane, and the single membrane filament tensile force is greater than 50KG. It is aptly called "pull continuous film".

2.Good anti-pollution performance:

Reinforced composite PVDF hollow fiber membrane adopts PVDF alloy formula as its filtration layer, and its ultra-smooth membrane surface characteristics and unique charge performance make it have strong anti-pollution performance.

3.Super-large flux:

The reinforced composite PVDF hollow fiber membrane adopts a relatively independent special support layer technology and PVDF alloy membrane filtration layer technology, and the formed filter layer has high porosity, and the produced membrane not only has high strength but also good flux.

4.Good retention performance:

The reinforced composite PVDF hollow fiber membrane adopts PVDF alloy membrane as the filtration layer, and its special inner and outer dense double skin structure makes it have excellent retention performance.

5.The cleaning flux recovery is good:

The reinforced composite PVDF hollow fiber membrane adopts PVDF alloy membrane as the filtration layer, and its special inner and outer dense double skin structure makes the pollutants only stay on the outer surface of the membrane and does not enter the membrane network. Inside the hole, it is very easy to clean and the cleaning flux is restored.

6.The reinforced composite PVDF membrane module can be modularized, compact in structure, small in footprint, and easy to use in combination.

7.Reinforced composite PVDF sewage treatment special diaphragm has a long service life, generally can reach 3-5 years.

8.The composite PVDF membrane has good chemical stability, acid and alkali resistance, bacterial corrosion resistance and good oxidation resistance.

9.The membrane module is provided with an aeration tube to wash the membrane wire with water and water to maintain the flux of the membrane. The surface of the membrane fiber can also be cleaned by the aeration process of the biochemical pool to maintain a stable water production.

Hollow Fiber MBR Performance Parameter

|

Model No. |

MBR-10-PVDF |

MBR-15-PVDF |

MBR-20-PVDF |

|

Membrane Area |

10m2 |

15m2 |

20m2 |

|

Air Flow Rate |

3.5-4 m3/h.pcs |

4-4.5 m3/h.pcs |

4.5-5 m3/h.pcs |

|

Length |

1010mm |

1515mm |

2020mm |

|

Width |

535mm |

535mm |

535mm |

|

Thickness |

45 mm |

45 mm |

45 mm |

|

Porosity |

50-70% |

||

|

Longitudinal strength |

≥ 120 MPa |

||

|

Outlet |

32mm |

||

|

Air Inlet |

NA/DN25 |

||

|

Fitting Material |

ABS/UPVC |

||

|

Membrane Material |

PVDF |

||

|

Average Intercepting Aperture |

0.05μm |

||

|

Hollow Fiber Inner |

1.1mm |

||

|

Hollow Fiber Outer |

2.2mm |

||

|

Working Pressure |

-0.01~-0.05 MPa |

||

|

Water Turbidity |

< 1 NTU |

||

|

Effluent suspended solids |

< 1 mg/L |

||

|

Life |

3-5 years |

||

|

Packaging Material |

PU/EPOXY |

||

|

Temperature Range |

5-40℃ |

||

|

Feed Water Residual Chlorine |

0-200 ppm |

||

|

Washing Residual Chlorine |

0-5000 ppm |

||

|

PH Range |

2-11 (washing pH range: 1-12) |

||

|

Water Production Flow |

10-30L/ m2.h (according to different feed water) |

||

|

Maximum Transmembrane Pressure Difference |

-0.08 MPa |

||

|

Outlet Way |

Negative Pressure Suction |

||

|

Running Way |

Working 8min, Stop 2min |

||

|

Chemical Sterilization Pharmacy |

Sodium Hypochlorite |

||

|

Chemical Cleaning Cycle |

6-12 months |

||

|

Chemical Cleaning Pharmacy |

Citric Acid/Sodium Hypochlorite |

||

MBR system recommended design flow rate

|

Feed Water |

Design Flow Rate(L/M2.H) |

|

domestic sewage |

15-20 |

|

industrial sewage with low load |

10-15 |

|

industrial sewage with high load |

8-10 |

|

garbage permeate |

6-8 |

Feed water limited

|

animal and vegetable oil |

≤15 mg/L |

|

mineral oil |

≤2 mg/L |

|

Particle size |

≤2 mm |

|

calcium and magnesium ions |

Properly increase the biochemical residence time according to the actual situation |

|

BOD |

0.05-0.15 (kg-BOD/kg activated sludge·d) (standard value is 0.07) |

Activated sludge limited

|

MLSS |

3,000~12,000mg/L (Better:5000~10000mg/L) |

|

Temperature |

5-40℃ (Better: 15-35℃) |

MBR with frame Design(Reference)

|

Model No. |

MBR-190TPD-15 (domestic sewage) |

MBR-250TPD-20 (domestic sewage) |

|

Average Production Flux |

190 m3/day |

250 m3/day |

|

Unit Model |

MBR-15-PVDF |

MBR-20-PVDF |

|

Quantity of the Unit |

44 units(15 square meter) |

44 units(20 square meter) |

|

Membrane Area |

660 m2 |

880 m2 |

|

Outlet |

DN50 |

DN50 |

|

Inlet |

DN80 |

DN80 |

|

Frame Length |

2200 mm |

2200 mm |

|

Frame Width |

1500 mm |

800 mm |

|

Frame Height |

1800 mm |

2400 mm |

|

Liquid Level |

>2100 mm |

>2700 mm |

|

MBR Tank Height |

>2400 mm |

>3000 mm |

|

Frame Air Flow Rate |

220 m3/h |

220 m3/h |

|

Frame Spacing |

300-500 mm |

300-500 mm |

|

Recommended Aeration (Gas to Water Ratio) |

>15:1 |

>15:1 |

|

Frame Material |

Stainless Steel Tube PVC Slot |

Stainless Steel Tube PVC Slot |

Hollow Fiber MBR Module Pictures

Conditions and Methods of using

1. Membrane hydrophilicity and moisturizing

The reinforced composite PVDF membrane adopts hydrophilic modified PVDF raw material, and the membrane has good hydrophilicity, and no hydrophilic treatment is needed at the site. However, if the diaphragm is not put into use immediately after installation, or if it needs to be parked for a while during use, please ensure that the diaphragm is submerged in water or always wet.

2. Membrane flux maintenance and membrane cleaning

The aeration system of the diaphragm is constructed by using a perforated aeration method, and the bubbles and water flow generated by the aeration are fully shaken to achieve self-cleaning of the membrane. The intermittent operation mode is adopted, and the self-priming pump suctions for 10 to 12 minutes and stops for 2 to 3 minutes, which can effectively prevent the membrane pores from being clogged and ensure long-term and stable operation of membrane separation. When used for the first time, the biochemical pool microbial culture achieved good activity, and when the viscosity was small, the membrane began to be put into operation.

When the system is running, the constant flow method is adopted, and the suction negative pressure can be read by the electric contact type pressure gauge, and the initial diaphragm operation negative pressure is -0.01 to -0.03Mpa. When the conditions permit, the water can be siphoned, but the difference between the liquid level of the biochemical pool and the outlet pool should be 3.0-4.0 meters, the membrane is less likely to be polluted, the water is more stable, and the service period is longer. When the operating negative pressure exceeds -0.06 MPa, the diaphragm needs to be chemically cleaned in time. The cleaning method is to place the membrane stack in the chemical cleaning tank or the membrane module piece is removed from the membrane frame, rinse the surface of the membrane with clean water, remove the activated sludge attached to the surface of the membrane, and soak for several hours with a 0.5% NaClO solution. The bacteria adhering to the surface of the membrane are killed, the organic matter and the colloidal substance attached to the surface of the membrane are removed, and the membrane is washed with water, and the membrane flux can be recovered. If the salt in the water is more likely to scale on the surface of the membrane, it can be soaked with 2 to 3% hydrochloric acid for about 1 hour. Care should be taken in cleaning to prevent damage to the membrane.

3. Transportation and handling

The entire transportation process should ensure that the ambient temperature of the device is within the range of 5-40 °C to avoid damage to the diaphragm. And avoid exposing the device to sunlight, so as not to damage the engineering plastics on the device.

Packaging