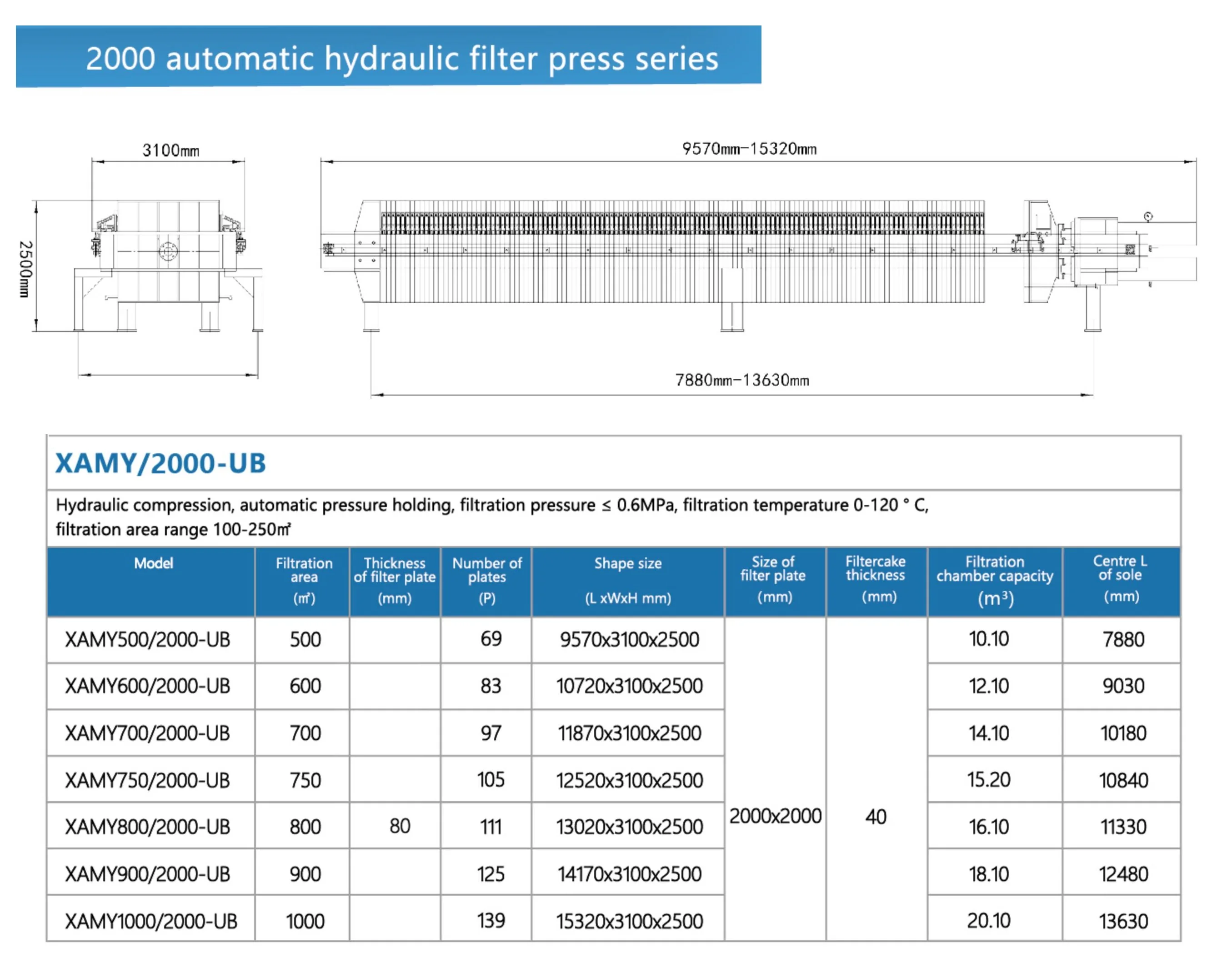

Product

Contact Us

Filter Press

Product features

1. The hydraulic device is used as the power device to compress and loosen the filter plate;

2. The frame is welded with high-quality solid steel plate, with high strength, stable structure, long service life,high-strength anti-corrosion treatment on the surface and long service life;

3. The upper part of the main beam is covered with 304 stainless steel, which can effectively reduce the frictionresistance between the filter plate and the main beam and reduce the working intensity:

4. The integrated hydraulic and electric control system adopts well-known brand components, and the mainbody of the hydraulic system valve is precision machined to ensure durability;

5. The filter plate adopts brand-new raw materials and formula, high-pressure molding, strong quality, highworking pressure, high filtration efficiency, no blocking, no plate breaking, and has the characteristics of highstrength, light weight, corrosion resistance, acid and alkali resistance, non-toxic and tasteless;

6. The high standard process of large-scale pressing and one-time forming is adopted, which is simple andpractical, with box type middle feeding and plate frame type upper corner feeding;

7. High standard production process and technology are adopted, and a variety of safety devices are equippedto ensure the safety of operators, simple operation and convenient maintenance.

Working Principle

Filter press is an intermittent pressurized filtration equipment, which is used for solid-liquid separation ofvariosuspensions. The filter plate is pressed by the pressing device, and then the suspension material pump ispressed into the filter chamber to separate the solid particles from the liquid materials through the filter cloth.

1. The filter press is composed of field frame, filter plate, pressing system (manual, mechanical andhydraulic) and electrical control cabinet.

2. The frame part plays the role of supporting the pressing device and filter plate, and is composed of base,pressing plate, thrust plate and main bea

3. The filter plate is installed on the main beam of the same compression plate and thrust plate, with filtercloth sandwiched between them.

4. During operation, the pressing device (oil cylinder piston rod or lead screw) pushes the pressing plate topress the filter plate and filter cloth between the pressing plate and the thrust plate, and a filter chamber isformed between the pressed filter plate and the filter plate. The material pressed by the feed pump enterseach filter chamber from the feed hole of the thrust plate, the solid frequency particles are intercepted in thefilter chamber, the well forms a filter cake, and the liguid is discharged from the machine through the filtercake and filter cloth through the liquid outlet hole.

5. The liquid flow form of filter press is divided into open flow and dark flow. Open flow refers to that the filtrate is directly discharged out of the machine through the outlet hole of each filter plate; Undercurrentrefers to that the filtrate of each filter plate is combined and discharged out of the machine through theliquid outlet channel.Applicable to a wide range of countries.

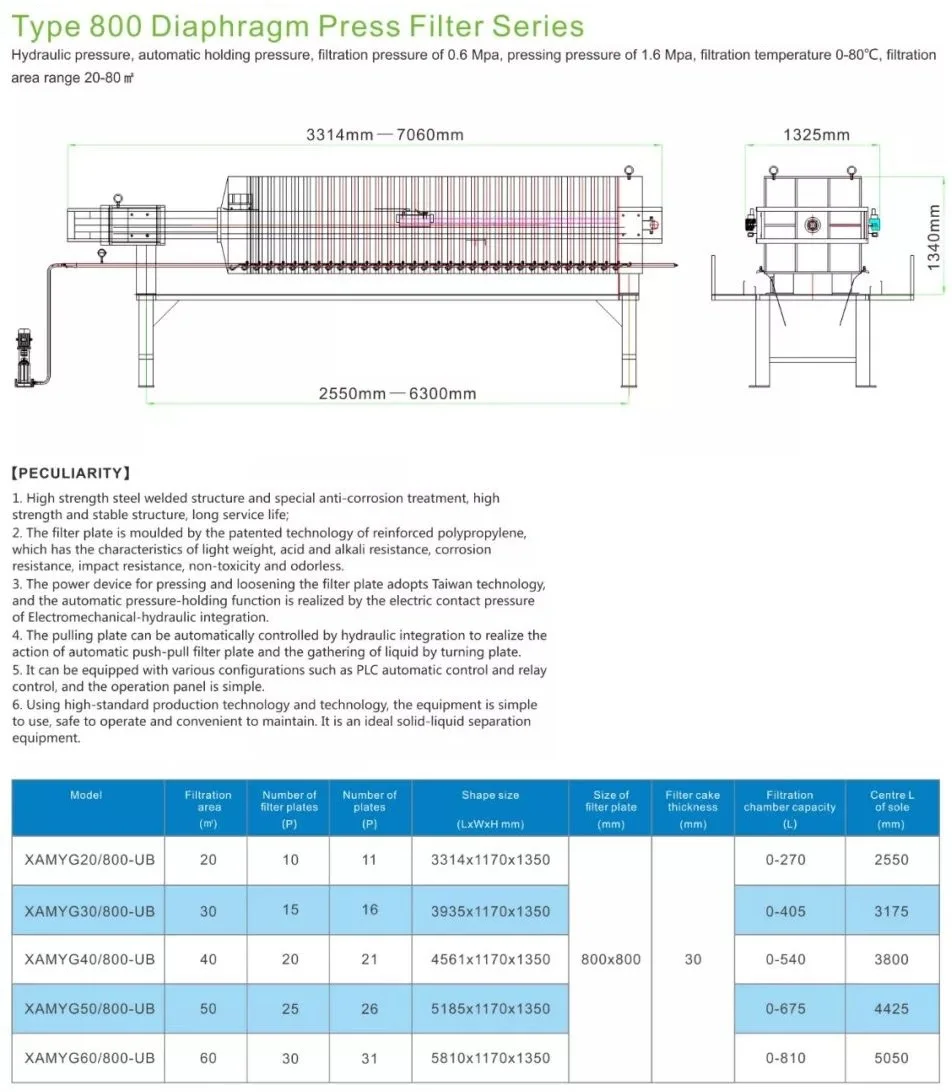

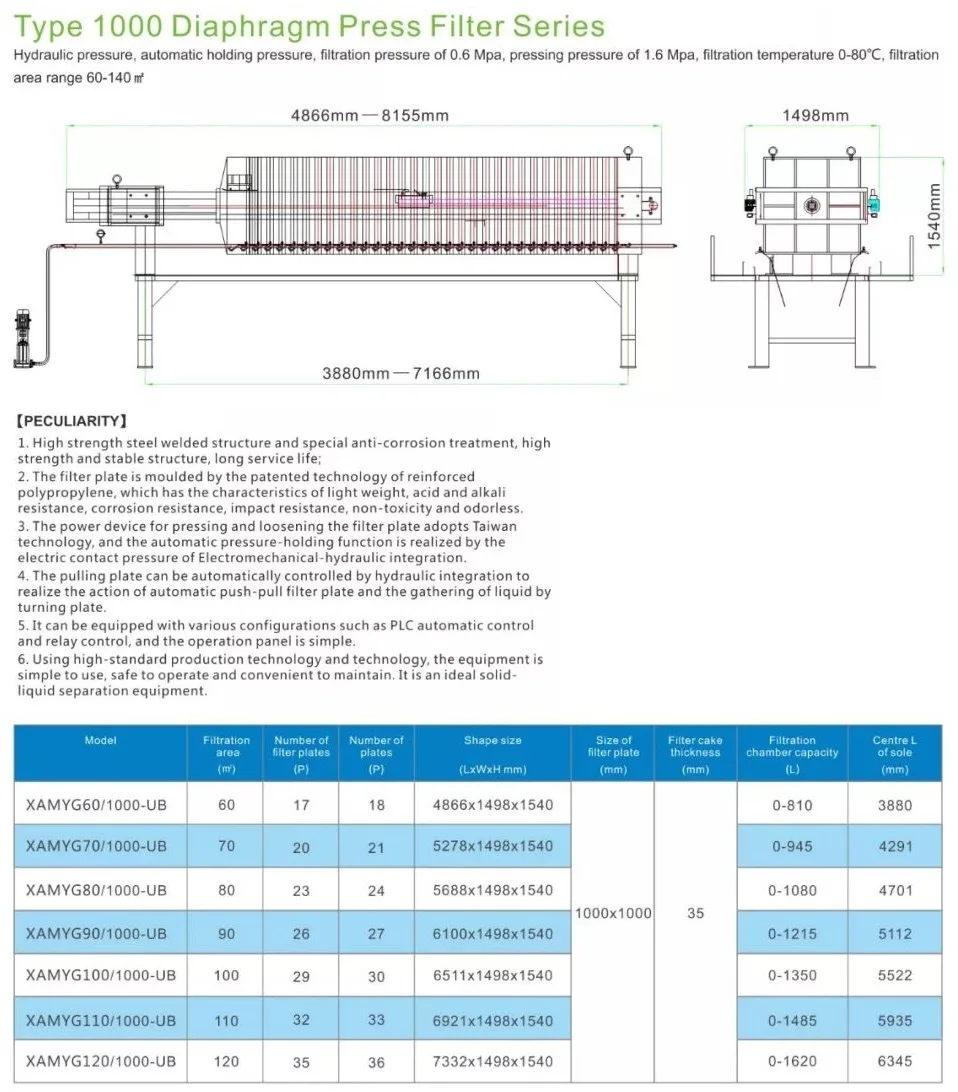

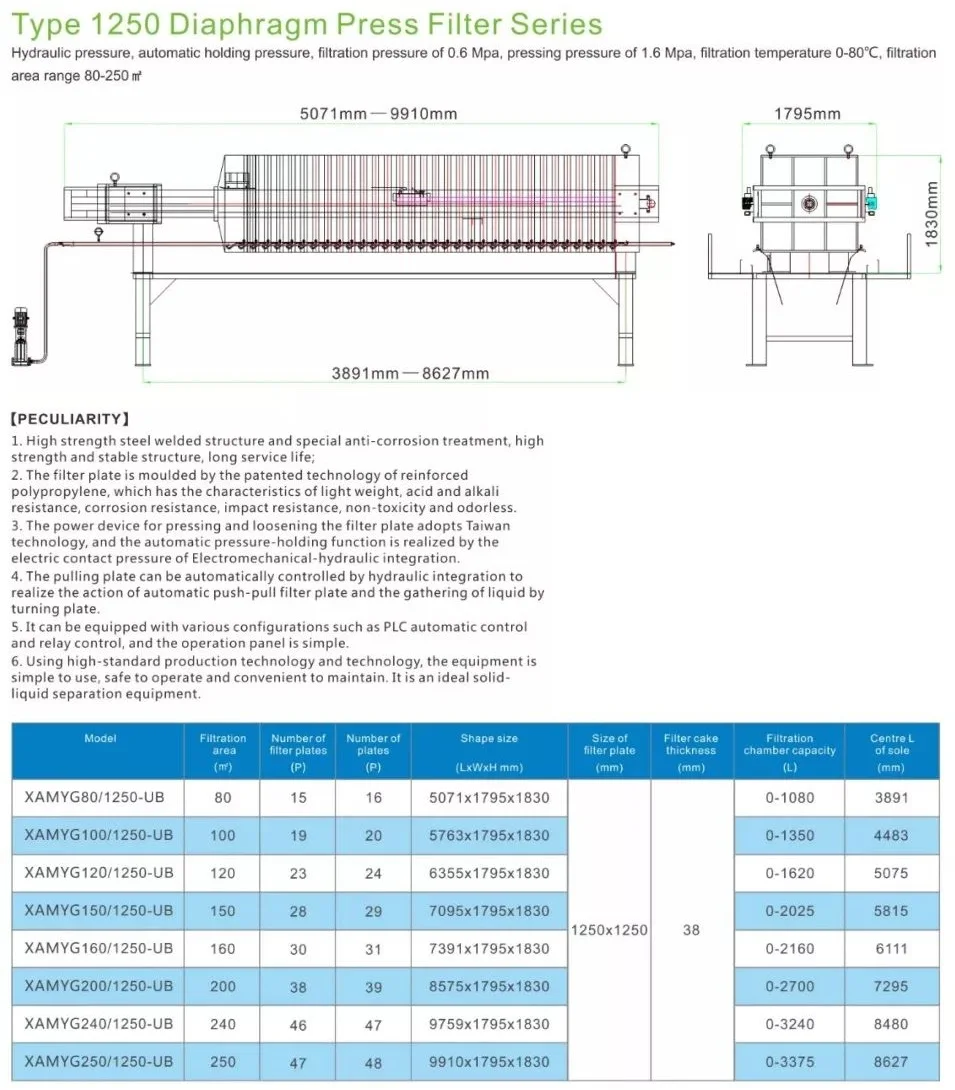

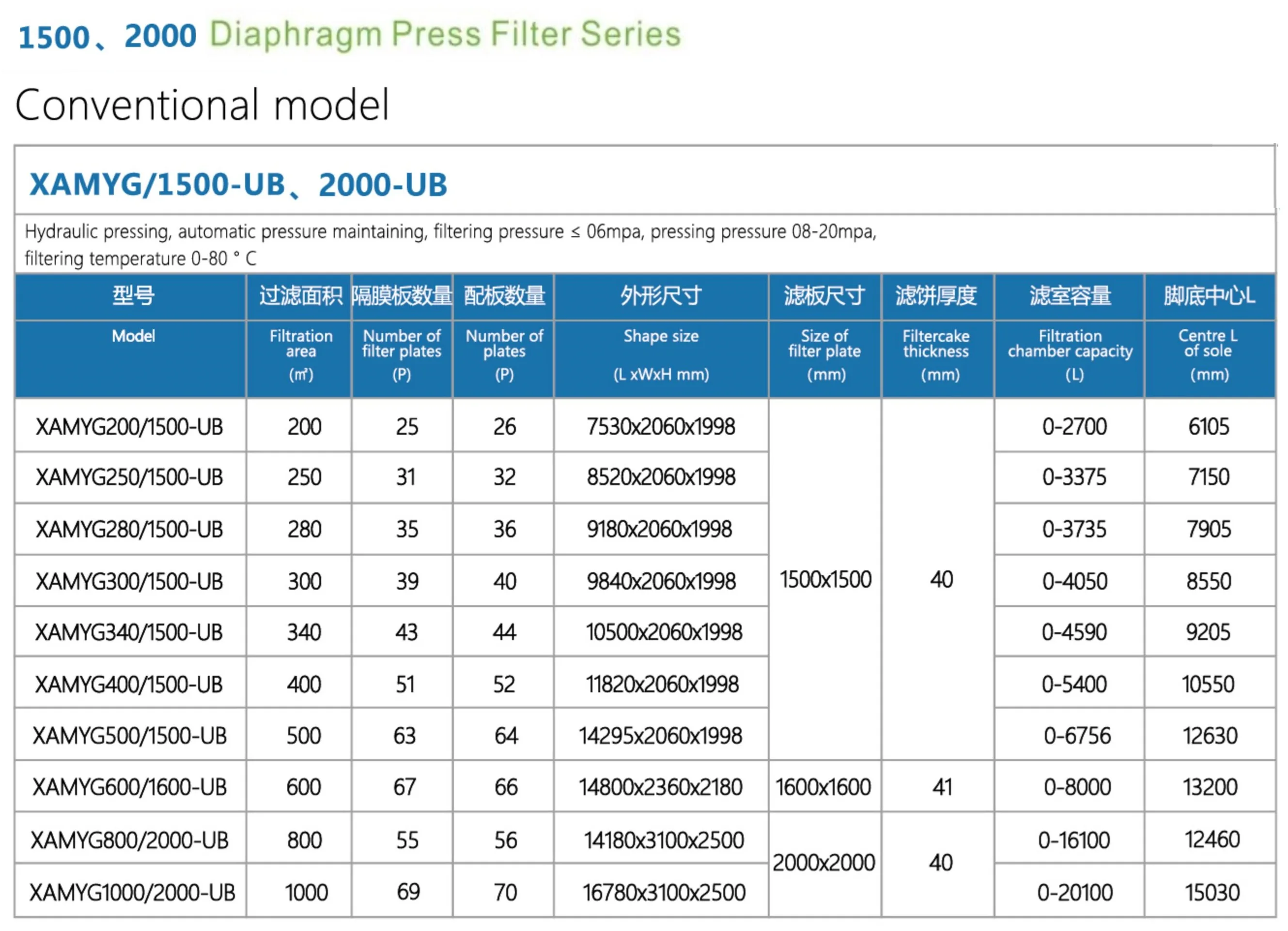

Diaphragm Plate and Frame Filter Press

Product features

1. The diaphragm filter press in the late filtration, low flow, high pressure, can greatly reduce the energyconsumption of power operation, played an energy-saving role.

2. lmprove the biscuit degree of mud and reduce the moisture content of mud cake. After the staticfiltration, the filter cake is pressed twice, which makes the density of the filter cake increase, thusextruding more moisture and improving the dry degree of the filter cake.

3. The low biscuit degree of mud cake reduces the adherence of mud cake to filter cloth, the speed ofseparation from filter cloth is faster, the working period is shorter, and the pressing efficiency isimproved.

4. The box-type filter plate and the membrane filter plate of the diaphragm filter press can withstand thepressure of 13 kg/17 kg, with high strength and strong corrosion resistance, and can meet the require-ments of solid-liquid separation in different industries, basically applicable to all solid-liquid separationoperations.

5.PLC industrial control system can be used for mud unloading, which can greatly reduce manual laborintensity and improve the efficiency of solid-liquid separation.6. The membrane filter plate sealing performance is good, in the pressing process, the dripping phe-nomenon is not obvious than the ordinary box filter press, the pressing environment is clean and tidy.

Working Principle

Diaphragm filter press, that is, diaphragm filterpress, is a filter press with a layer of elasticmembrane installed between the filter plates.One machine includes two kinds of filter plates.one is ordinary box filter plate and the other isdiaphragm filter plate. During the use of thefilter press, when the feeding is finished, thehigh-pressure fluid (clean water) or gas (air)medium can be injected into the diaphragmplate. At this time, all diaphragm plates of theequipment will bulge and press the filter cake. so as to realize the further dehydration of the filter cake and achieve better treatment effect. According to thesecondary pressing method, it can also be divided into two types: air extrusion and water injection extrusion.In terms of pressure stability and strenath, it is recommended that the customer choose the second one andinject water for secondary extrusion.

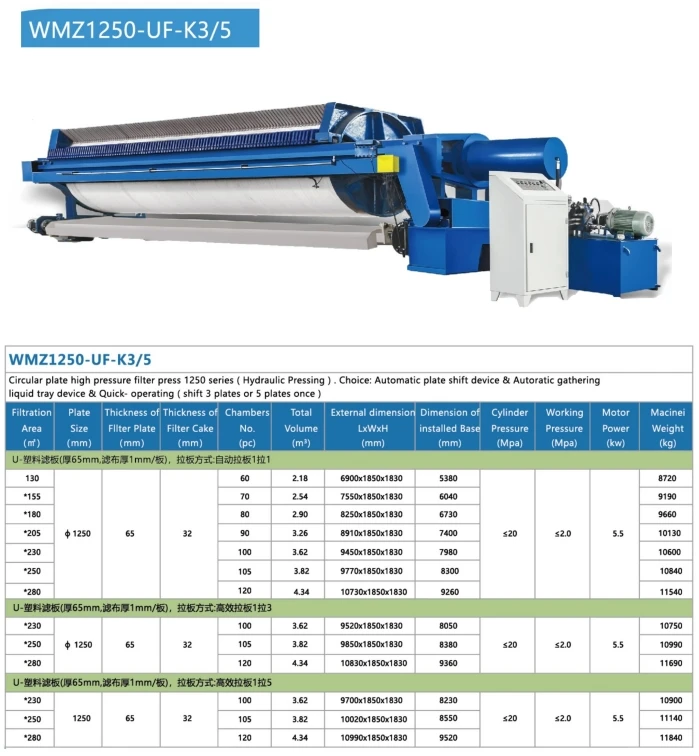

Disc Filter Press

Product features

1. Adopt PLC automatic control to realize automatic pull plate and turn plate collecting liquid, highautomation degree, reduce operator

2. Adopt automatic pick up liquid turn plate device, completely solve the separation of slag and water,improve product quality and beautify the environment;

3. The filter plate adopts imported high polymer PE patent technology high pressure pressing molding.ensure each filter plate service life longer;

4. According to the material performance, specific gravity, project diferent, can be selected accordingto customer demand, a high-efficiency open 3-6 filter plate, save unloading time, general materials,materials can increase solid content of 10% ;

5. The use of high-standard production technology and technology, quality, to ensure that eachproduct in the industry leading level,

6. Electro-hydraulic integrated automatic control and relay control and other configuration, simpleoperation panel,

7. High pressure, high output, low energy consumption, stable and reliable, is the ideal solid-iquidseparation equipment.

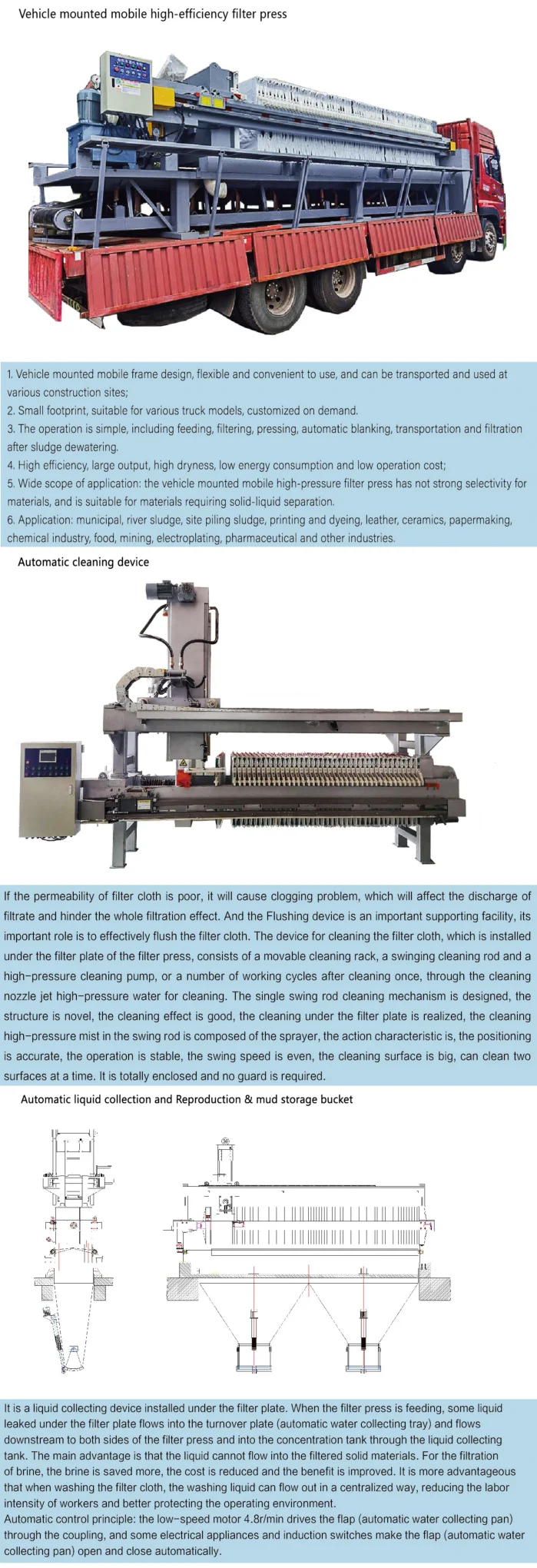

Upgrade Custom Filter Press

Product Show