Product

Contact Us

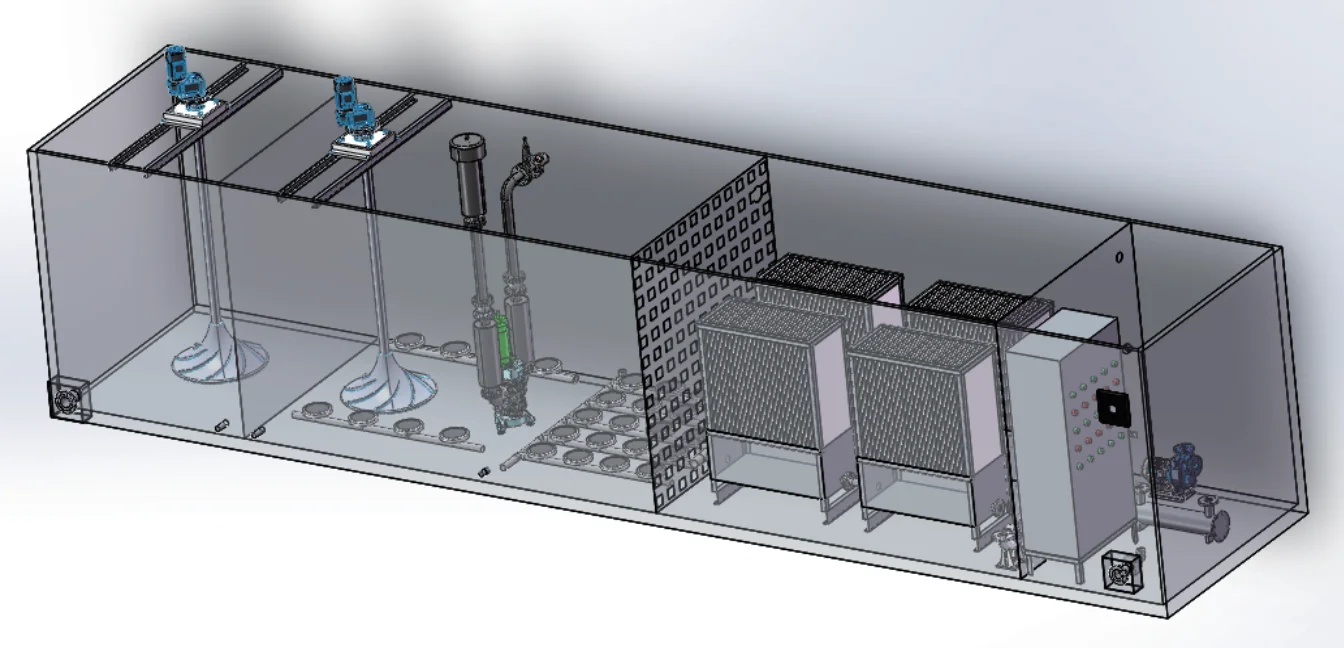

Compact Unit Reactor of WWTP

Intelligent Compact Unit

General Introduction

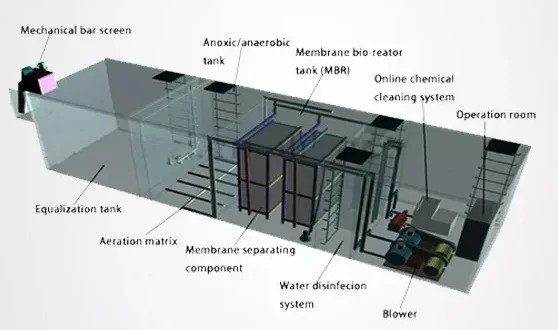

The compact unit adopts the standard container as its main body, which is convenient for transportation. The treatment capacity of one unit is 50-200m3/day. We specially developed this system according to the characteristics of urban and rural domestic wastewater, the general industrial waste water and black smelly river course. The wastewater treatment technology AO + MBBR and AO + MBR are adopted to achieve high treatment efficiency and stable effluent quality.

The effluent quality can meet "Class I A / B standard Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB18918-2002) or Class quasi-IV Standard of Environmental Quality Standards for Surface Water (GB3838-2002).

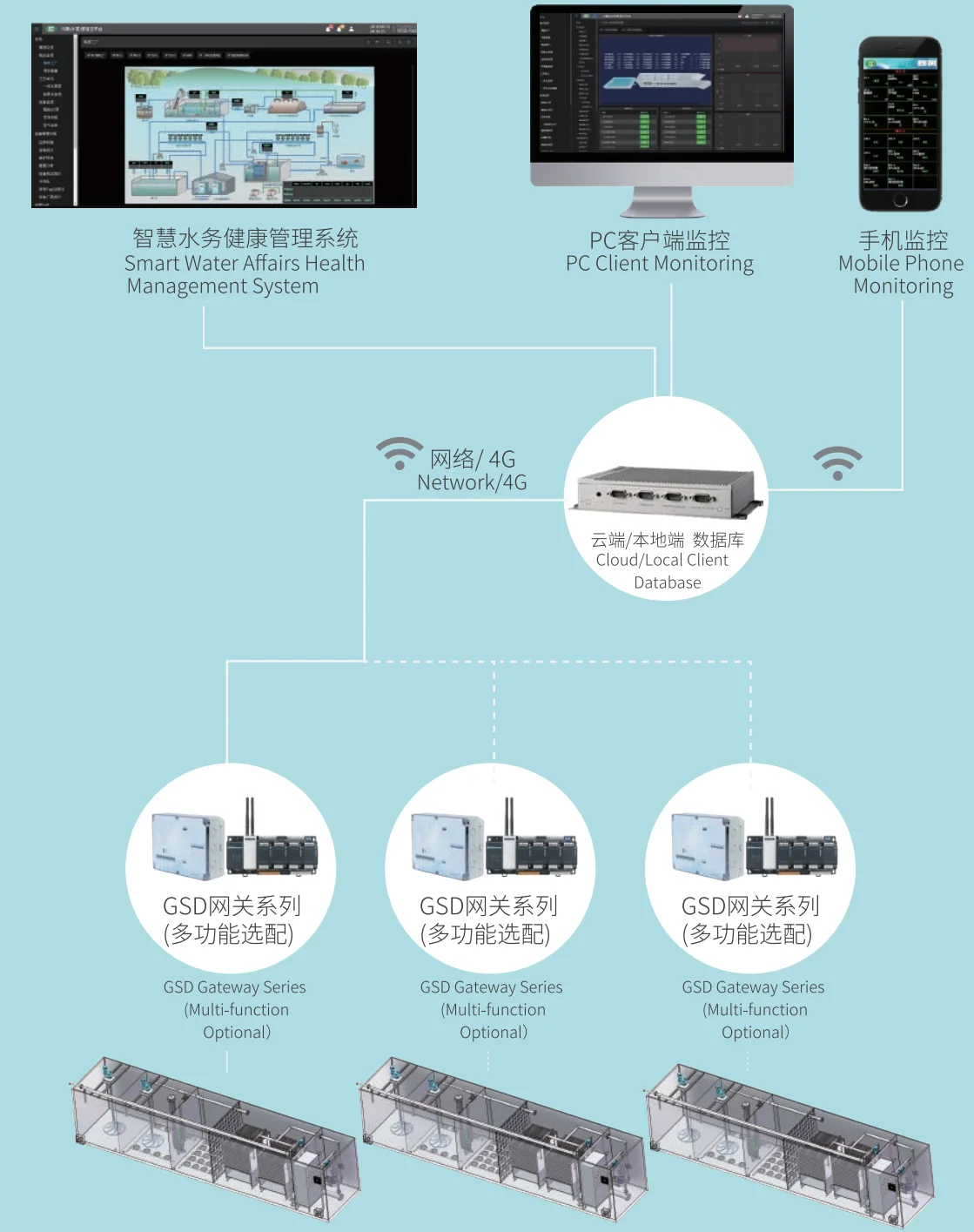

The equipment is equipped with intelligent modules and monitoring systems to realize the digitization and interconnection of compact unit, which can further achieve intelligent functions such as unmanned operation, remote supervision and risk warning, and enhance the user experience.

Applications

Rural/township domestic sewage treatment, no municipal official website scenic area domestic sewage treatment.

Suitable for residential quarters, office buildings, shopping malls, hotels, restaurants, government schools, military units, factories and other domestic sewage.

Similar industrial organic wastewater, such as organic wastewater treatment in textile, beer, paper, leather, food, chemical and other industries.

Black odor water body control source interception, etc.

System architecture

Features

Real-time equipment operation monitoring and water quality monitoring, abnormal alarms, reduce losses.

Support remote equipment control, improve emergency response capabilities, and reduce labor costs for inspections.

The professional decision-making module provides maintenance suggestions and includes fault warning functions to extend the service life of the equipment.

Intelligent management can operate in GSD equipment management system or on the customer's own platform.

Provides multiple service solutions for single and multiple compact units, and can realize centralized management of multiple scattered compact units.

The compact unit is refabricated packaged system of high-quality, which is assembled in the factory, and on-site construction period is short.

The modular design of container specifications makes transportation fast and convenient, and facilitates capacity expansion.

Provide MBBR and MBR process options, strengthen the stability of sewage treatment, and have strong impact resistance.

The system has a long retention time of sludge and less sludge production, which reduces the burden of sludge disposal.

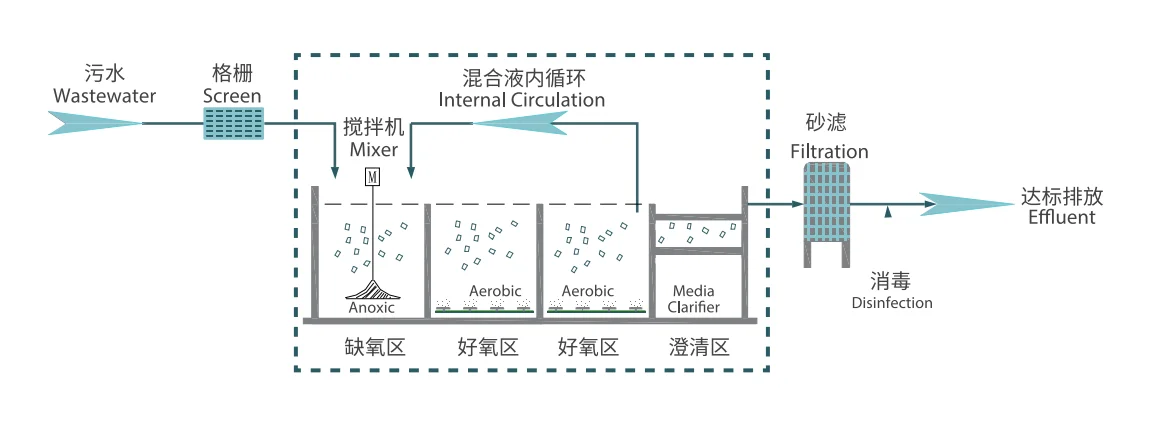

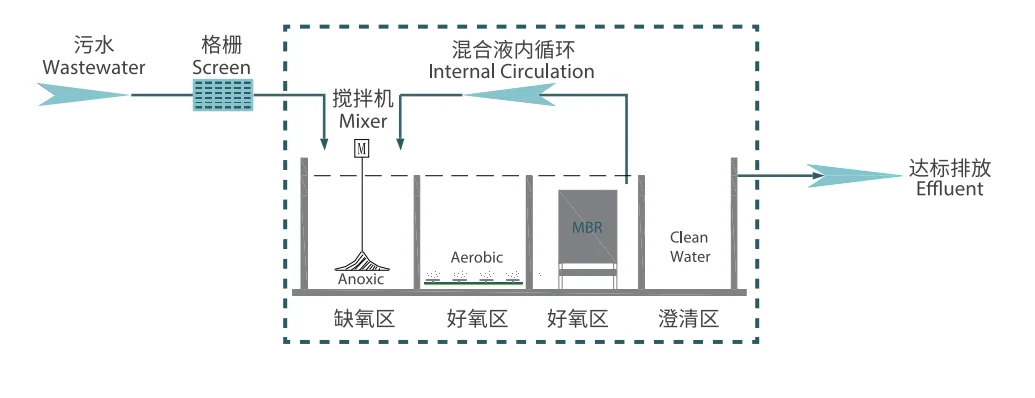

Technical process

AO+MBBR process:

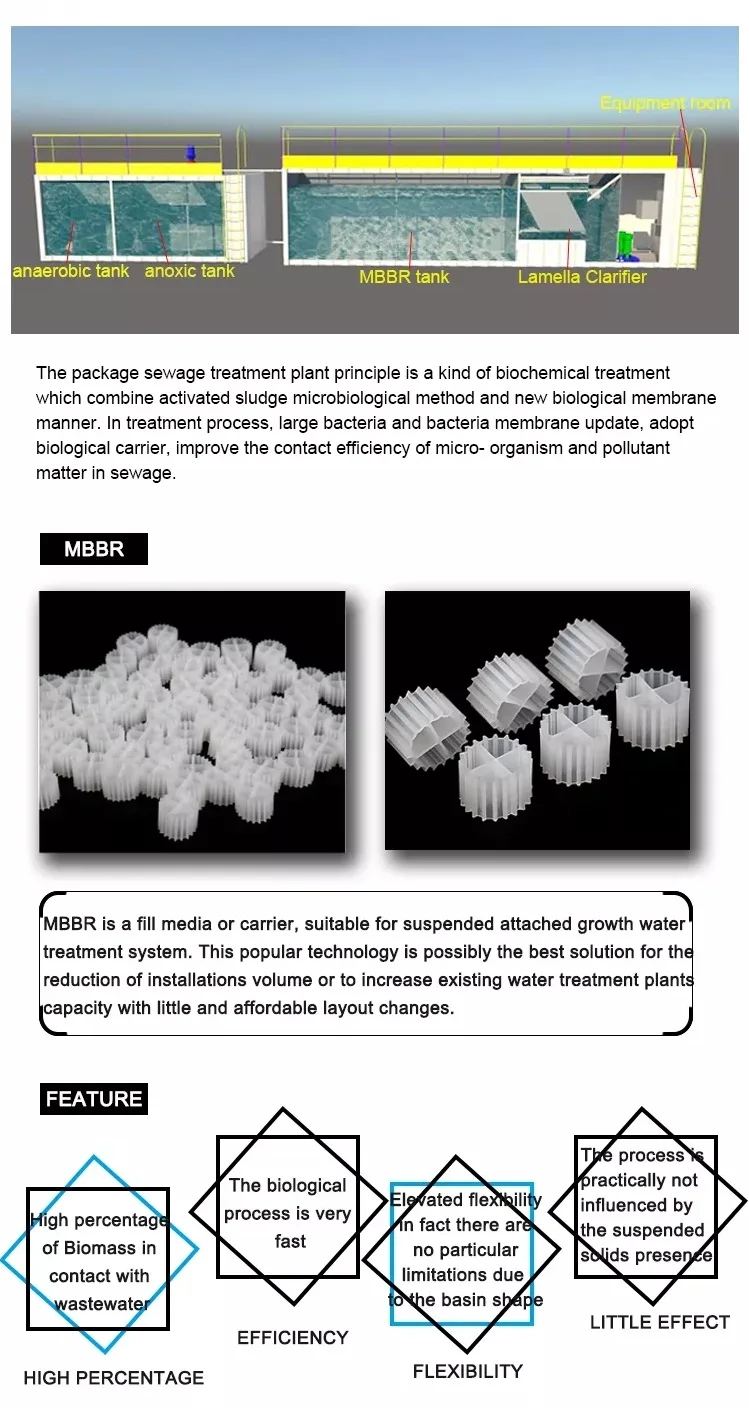

The MBBR process is a new and efficient wastewater treatment method, which combines the advantages of both traditional fluidized bed and biological contact oxidation processes.

MBBR process principle

Using the basic principles of the biofilm method, the advantages of activated sludge are fully utilized, and the shortcomings of the traditional activated sludge method and the fixed biofilm method are over- come.The method increases the treatment efficiency of the reactor by aciding a certain amount of suspension carrier to the reactor to increase the biomass and biological species in the reactor. Since the packing density is close to that of water, it is completely mixed with water during aeration, and the environment in which microorganisms grow is gas, liquid, and solid three phases.

MBBR process features

The processing load is high, and the volume load is 2 to 4 times that of the conventional one.

The oxidation tank has a small volume, which reduces infrastructure investment.

In the MBBR process, sludge backflow is not required, no backwashing equipment is required, equipment investment is reduced, operation is simple, and the operating cost of sewage is reduced.

The MBBR process sludge yield is low, which reduces sludge disposal costs.

In the MBBR process, no filler bracket is needed, and the filling rate is directly added, and the filling rate is 10%-70%z which saves installation time and cost.

AO+MBR process:

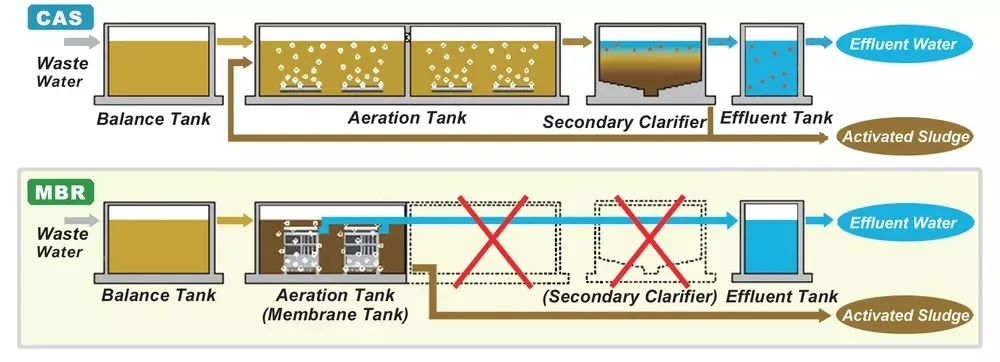

MBR process is a new water treatment technology, which combines activated sludge method and membrane separation technology.

MBR process principle

MBR is the abbreviation of Membrane Bio-Reactor, which is a new efficient waste water treatment technology combining modern membrane separation technology and traditional biological treatment technology. The MBR process combines the membrane separation technology in the separation engineering with the traditional waste water biological treatment technology, which not only saves the construction of the secondary sedimentation tank, but also greatly improves the solid-liquid separation efficiency.

Moreover, the increase of the mass concentration of activated sludge in the aeration tank and the emergence of specific bacteria (especially the dominant bacteria) in the sludge, could improve the biochemical reaction rate could be improved as well. Meanwhile, by reducing the F/M ratio, the excess activated sludge amount could be reduced (even to zero), and consequently, some outstanding problems existing in the traditional activated sludge process will be solved.

MBR process features

It can efficiently separate the solid from the liquid, the effect will be much better than the traditional sedimentation tank. The discharge water quality is great,the suspended solids and turbidity are close to 0, which then it can be reused directly and achieve the purpose of wastewater recycling.

The high efficient membrane interception enables the microorganism to be completely trapped in the reactor, realizing the complete separation of HRT and SRT, and makes the operation control more flexible.

The microorganism mass concentration in the reactor is high and resistant to the impact load.

It is beneficial to the growth and reproduction of slow-multiplying nitrifying bacteria. The nitrification efficiency of the system could be improved. By changing the operation mode, the system could also achieve nitrogen and phosphorus removal.

Intelligent Compact Unit

Specification type

|

Type |

Intelligent Compact Unit |

|||

|

CWU-50 |

CWU-100 |

CWU-150 |

CWU-200 |

|

|

Influent quality |

Typical domestic wastewater (COD<400mg/L, BOD5<250mg/L, NH3-N<35mg/L, TN<50mg/L, TPW5mg/L, SSW200mg/L) |

|||

|

Effluent standard |

GB18918-2002 First level A/B |

|||

|

Technical process |

AO+MBBR or AO+MBR |

|||

|

Treatment capacity |

50m3/d |

100m3/d |

150m3/d |

200m3/d |

|

Equipment dimentions |

20 Ft standard container *1 |

40 Ft standard container *1 |

20 Ft standard container *1 +40 Ft standard container *1 |

40 Ft standard container *2 |

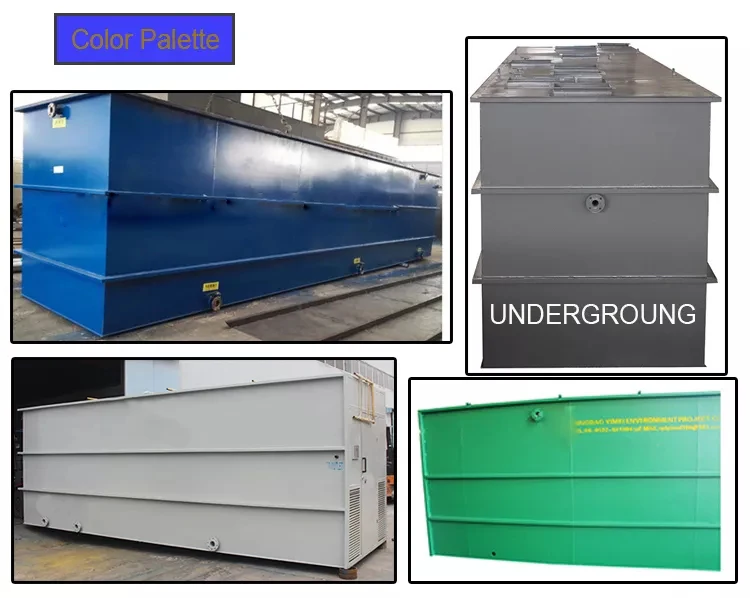

Product Show