Product

Contact Us

Al2O3 Ceramic Membrane

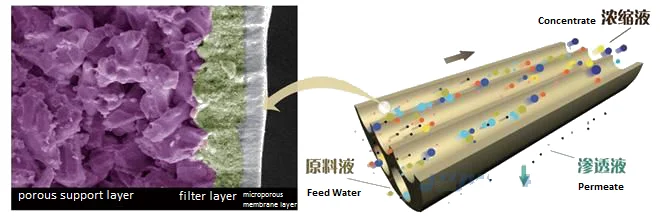

SEM photo of membrane section Diagram of ceramic membrane crossflow filtration

The inorganic ceramic membrane is sintered from Al2O3, TiO2 or ZrO2. It is a ceramic filter with a porous structure. The porous support layer, the filter layer and the microporous membrane layer are symmetrically distributed.Filtration accuracy includes microfiltration, ultrafiltration, and nanofiltration.

The Ceramic membrane filtration is a fluid separation process in the form of “cross-flow filtration”:

the raw material liquid flows at high speed in the membrane tube, and the clarified permeate containing small molecular components is driven through the membrane in a direction perpendicular to the pressure driven by the pressure. The turbid concentrate of the macromolecular component is trapped by the membrane, thereby allowing the fluid to be separated, concentrated, and purified.

Ceramic membrane advantages:

Good chemical stability, acid, alkali and oxidation resistance;

Resistant to organic solvents, high temperature resistance;

High mechanical strength and good wear resistance;

Long life and high processing capacity;

The pore size distribution is narrow, the separation precision is extremely high, and the nanometer filtration can be achieved;

Easy to clean, can be sterilized online or high temperature, can be backwashed

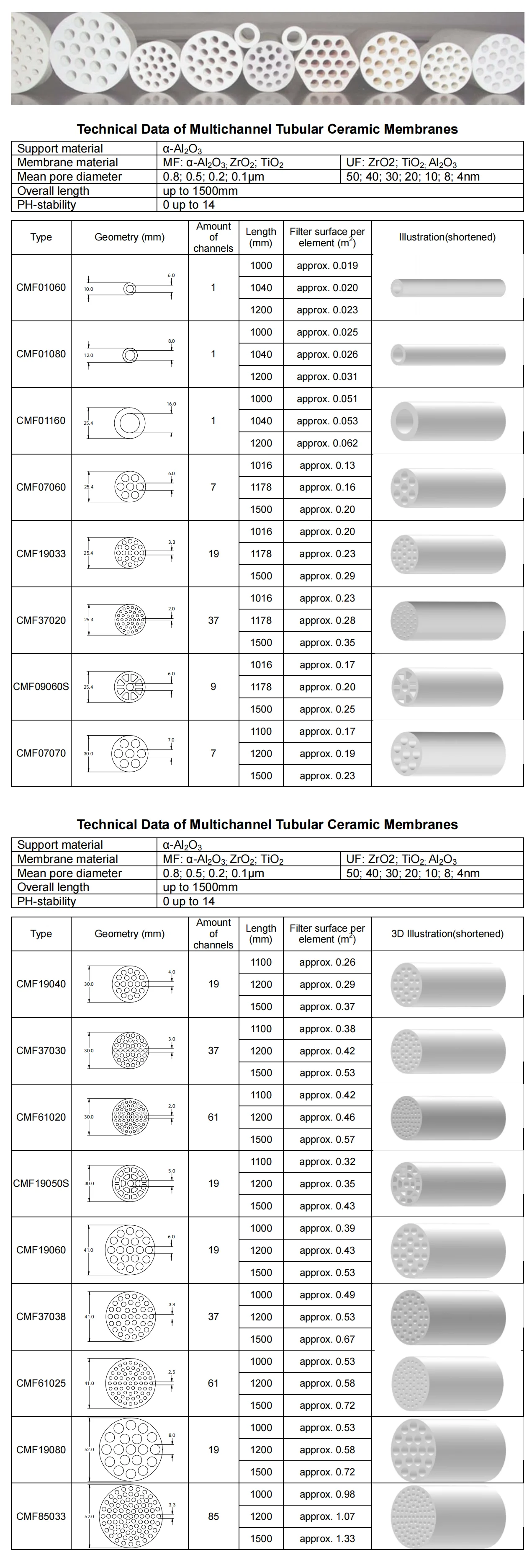

Specification

Ceramic Membrane Performance Comparison Table

|

Properties |

SIC Membrane |

UF Membrane |

Al2O3 Membrane |

|

Carrier Material |

100% SIC |

UPVC Material |

Al2O3 |

|

Filter Layer Material |

100% SIC |

PS\PVC\PAN\PVDF\PES |

Al2O3 |

|

Hardness |

High |

Low |

High |

|

Operating Pressure |

1-2 Bar |

1-2 Bar |

3-4 Bar |

|

Pure Water Flux |

3-4 m3/m2.h |

0.08-0.12 m3/m2.h |

0.25-0.5 m3/m2.h |

|

Resistant Temperature |

800 °C |

< 40°C |

<300°C |

| Al2O3 Ceramic Membrane Model | ||

| CM01*12 | CM19*25 | CM37*25 |

| CM07*30 | CM19*30 | CM61*30 |

| CM19*40 | CM37*40 | |

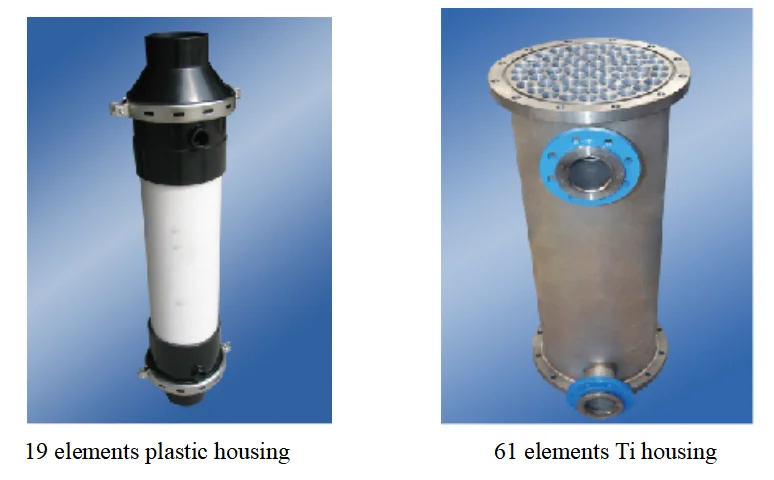

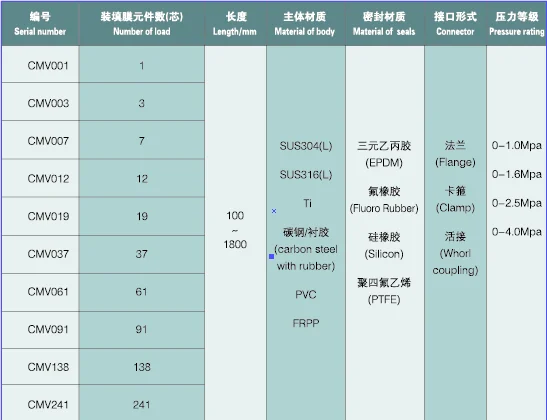

Membrane Housing

The company currently offers 1-element, 3-elements, 5-elements, 7-elements, 19-elements, 37-elements, 61-elements, 91-elements and 118 single-elements membrane housings. Customize the required membrane components according to customer needs and application scenarios. The materials are 304, 316, TI, PVC, FRPP.

The membrane module is a pressure resistant housing that is fitted with a ceramic membrane element. According to the needs of industrial production, centralized filling of ceramic membrane elements with different outer diameters and different areas can be realized by different module modules. The film area of a single membrane module varies from 0.02 m2 to 22 m2. The shape design and sealing design of the membrane module are essential for the operation of the ceramic membrane system.

Number of loaded membrane components: 1,3,7,12,19,37,61,76,91,138,241, etc.

Matching membrane element length diameter: 100 ~ 1800mm / outer diameter: 25, 30, 40mm

Body material: SUS304 (L), SUS316 (L), Ti, carbon steel with rubber, PVC, FRPP

Sealing material: EPDM, Fluoro Rubber, Silicone, Polytetrafluoroethylene (PTFE)

Interface form: flange (Flange), clamp (Clamp), joint (Whorl coupling)

Pressure rating: 0-1.0Mpa, 0-1.6Mpa, 0-2.5Mpa, 0-4.0Mpa

Standard: ISO, DIN / chemical grade, sanitary grade.