Product

Contact Us

Disc and Pipe Aerator

|

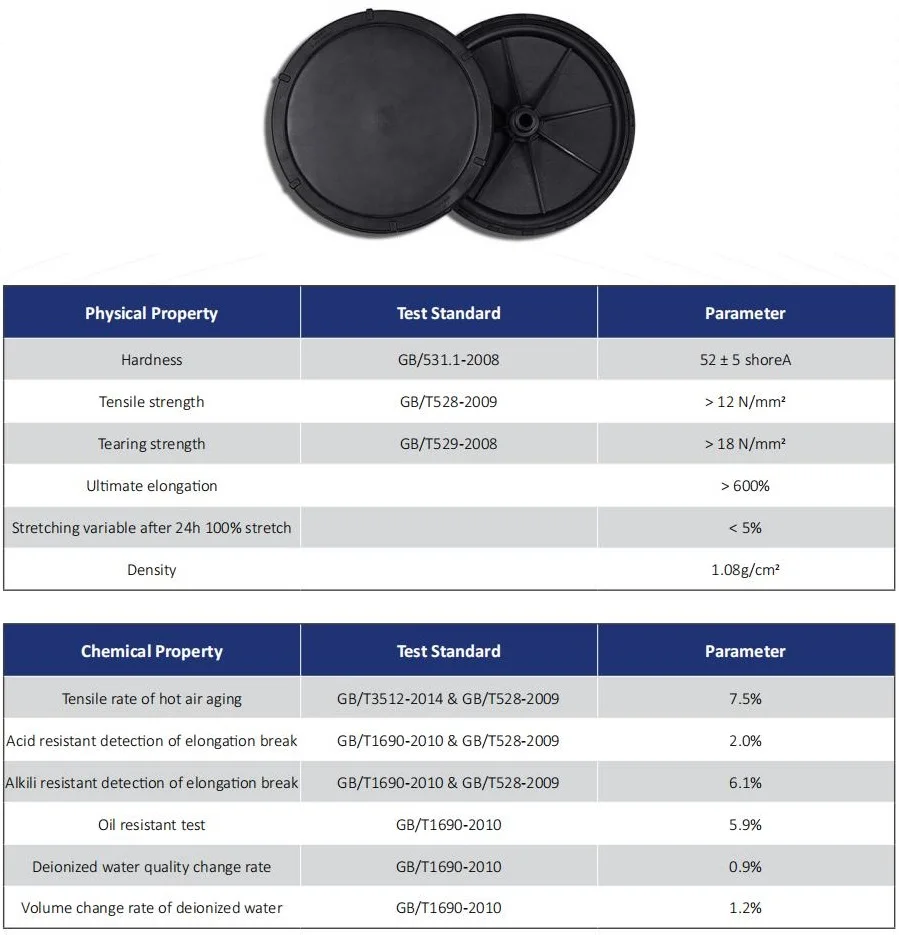

EPDM

|

SILICONE

|

| In municipal wastewater and most industrial wastewater, it can retain its physical properties for a long time, resist tearing, remain in shape after years of use, and produce tiny bubbles. Not suitable for solvent, grease, and high concentration of metal salts. | With stable material, the membrane will not harden or shrink. it has good resistance to organic solvent and grease -sewage , but its physical property is not as good as EPDM. It is suitable for industrial wastewater with high oil content and high temperature |

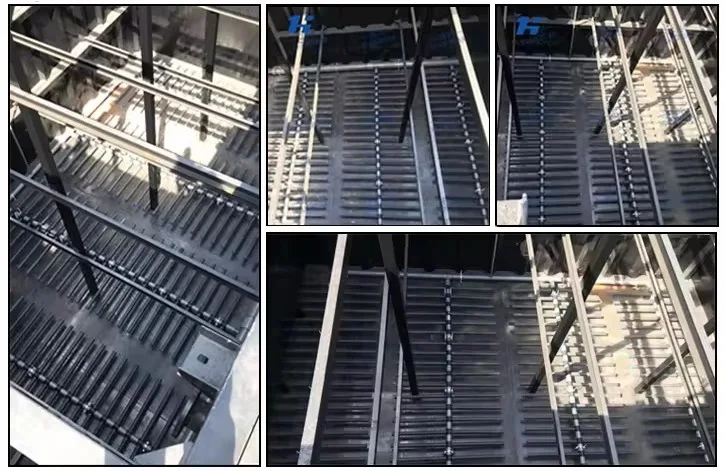

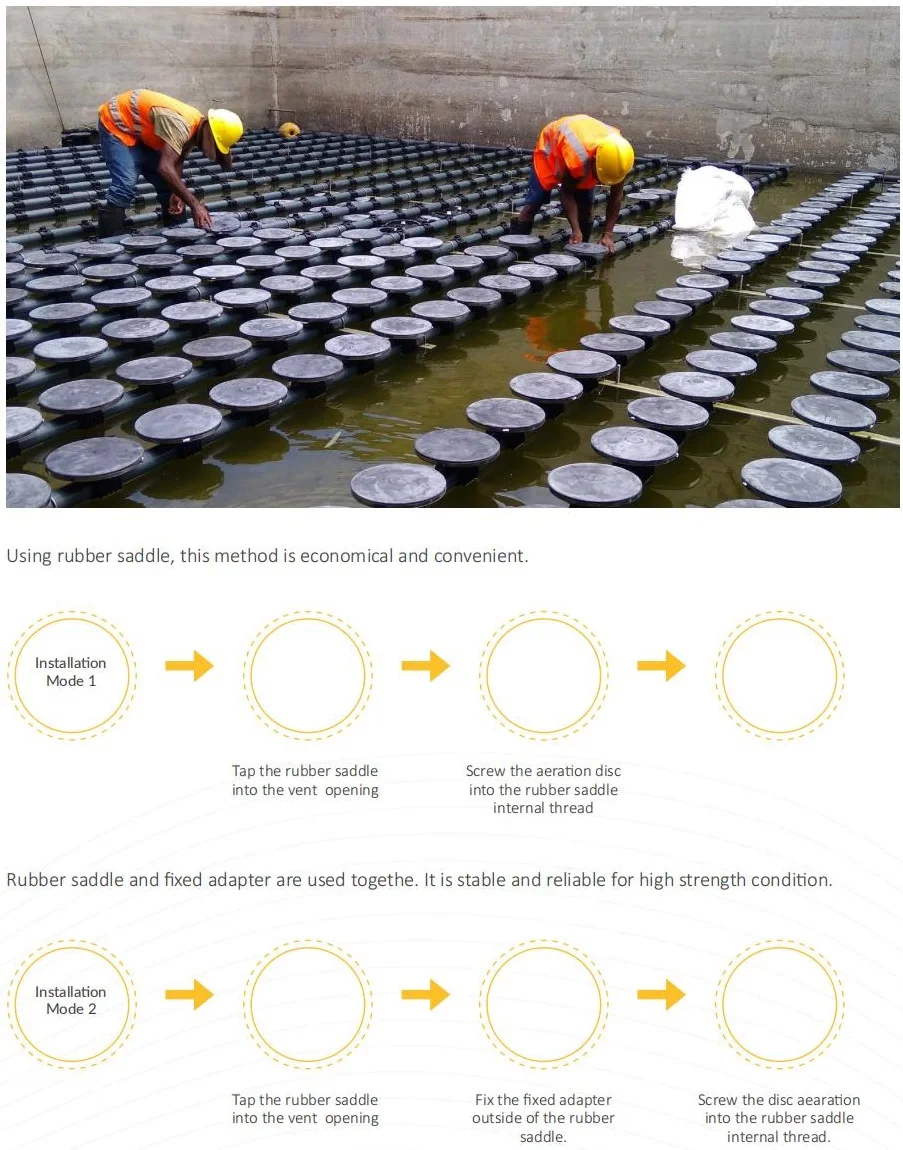

Product Show