Product

Contact Us

Description: Ultraviolet UV System Tube Type UV System Tube Type Ultraviolet System

Ultraviolet UV System

UV systems are a globally accepted solution for water disinfection due to being a chemical-free sustainable solution, combined with being able of inactivating bacteria, viruses, and protozoa, which makes the technology vital for the future of water disinfection.

Disinfecting water with UV systems is a very straightforward, yet extremely efficient method to ensure disinfected water.

The water flows through the piping system and through the UV chamber. In this chamber, the water is exposed to ultraviolet light, that is emitted from the UV lamps. The UV light from the lamps has a specific wavelength in the UV-C spectrum (around 254nm), that enables microorganism inactivation if exposed with the right intensity.

In technical terms, when the water comes into contact with UV light, the chemical bonds are broken down, which changes the DNA structure. It is this change in the DNA structure that disables the pathogens’ ability to perform vital cellular functions, including reproducing or causing infection.

Bacteria such as E. coli reproduce extremely rapidly. This is where the UV lamps come into action to damage the DNA or RNA of the microorganisms, which disrupts their ability to function and replicate.

Ultraviolet UV System Benefits

A lower carbon footprint in comparison to alternative disinfection methods

Low maintenance, administration, and OPEX costs

No dangerous chemicals involved (storage, handling, and residuals)

No by-products being created in the disinfection process

No change in the water properties such as pH and temperature

Instant treatment with no processing time

Simple and safe implementation

It is especially a beneficial alternative to chlorine disinfection, which can potentially result in health complications such as respiratory diseases, as well as being incapable of inactivating Cryptosporidium and Giardia.

Applications

|

TOC reduction Chlorine destruction Food & Beverage Life Sciences ... |

Microelectronics Disinfection Ozone destruction Chlorine/Chloramine destruction ... |

Aquaculture Marine Microelectronics Recreational Water ... |

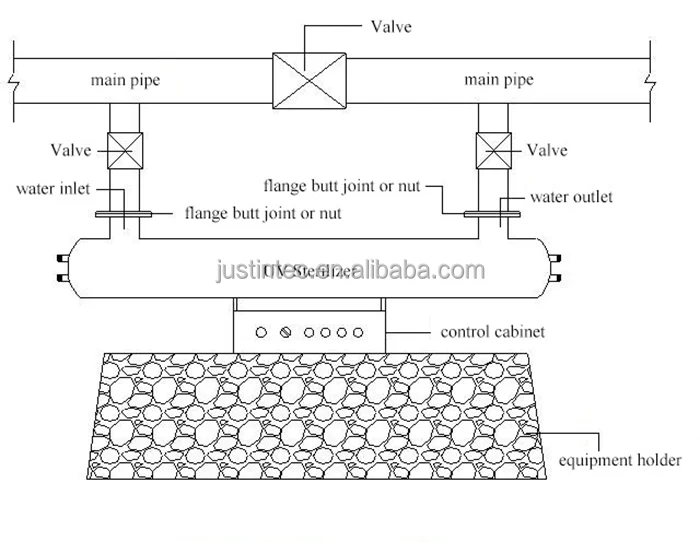

Closed Ultraviolet UV System

Ultraviolet UV System Components

UV lamps

The UV lamps are the heart of the UV system, which emits UV-C ultraviolet light to inactivate the microorganisms. With enough UV light exposure, microorganism inactivation will be achieved.

Quartz Sleeves

The quartz sleeves allow the UV lamps to do their job by protecting the lamp from water. To prevent fouling over time, quartz sleeve wiping can be integrated to consistently keep the quartz sleeves clean, allowing the UV lamps to stay close to full performance.

Reactor

The reactor is where the UV disinfection process takes place. As the water flows through the chamber, the UV lamps are doing their job to inactivate the microorganisms. Dependent on the water treatment challenge, the reactor material can consist of either stainless steel (SS), polypropylene (PP), or high-density polyethylene (PEHD).

Ballast

The ballasts ensure that the system is provided with the accurate electrical input it needs to maintain a stable operation.

Control Cabinet

The control cabinet is what controls the disinfection behind the scenes, by offering the operator control over the state of the system. Besides advanced functions, it is usually capable of sending out alerts if the lamps are not working correctly and providing info about the disinfection performance.

All these main components are a necessity for any operational UV disinfection system. The amount of them will however vary dependent on the disinfection challenge, where specific cases might require more lamps than others. For one closed vessel reactor, the UV systems can range from 1 lamp up to 56 UV lamps per unit.

|

Model |

Flow Rate |

Single Lamp Power |

Lamp Qty. |

Total Power |

Inlet/Outlet |

Max.Pressure |

|

UVC-120-2 |

10-12 |

120 |

2 |

240 |

DN65 |

0.6 |

|

UVC-100-3 |

12-15 |

100 |

3 |

300 |

DN65 |

0.6 |

|

UVC-120-3 |

15-18 |

120 |

3 |

360 |

DN80 |

0.6 |

|

UVC-100-4 |

18-20 |

100 |

4 |

400 |

DN80 |

0.6 |

|

UVC-120-4 |

20-23 |

120 |

4 |

480 |

DN80 |

0.6 |

|

UVC-100-5 |

23-25 |

100 |

5 |

500 |

DN100 |

0.6 |

|

UVC-100-6 |

25-30 |

100 |

6 |

600 |

DN100 |

0.6 |

|

UVC-120-6 |

30-35 |

120 |

6 |

720 |

DN100 |

0.6 |

|

UVC-120-7 |

35-40 |

120 |

7 |

840 |

DN100 |

0.8 |

|

UVC-120-8 |

40-50 |

120 |

8 |

960 |

DN150 |

0.8 |

|

UVC-150-7 |

50-55 |

150 |

7 |

1050 |

DN150 |

0.8 |

|

UVC-150-8 |

55-60 |

150 |

8 |

1200 |

DN150 |

0.8 |

|

UVC-150-9 |

60-65 |

150 |

9 |

1350 |

DN150 |

0.8 |

|

UVC-150-10 |

65-75 |

150 |

10 |

1500 |

DN150 |

1.0 |

|

UVC-150-11 |

75-85 |

150 |

11 |

1650 |

DN150 |

1.0 |

|

UVC-150-12 |

85-90 |

150 |

12 |

1800 |

DN150 |

1.0 |

|

UVC-150-14 |

90-100 |

150 |

14 |

2100 |

DN150 |

1.0 |

|

UVC-150-16 |

100-120 |

150 |

16 |

2400 |

DN150 |

1.0 |

|

UVC-150-18 |

120-135 |

150 |

18 |

2700 |

DN150 |

1.0 |

|

UVC-150-20 |

135-150 |

150 |

20 |

3000 |

DN200 |

1.0 |

|

UVC-150-24 |

150-180 |

150 |

24 |

3600 |

DN200 |

1.0 |

|

UVC-150-30 |

180-220 |

150 |

30 |

4500 |

DN200 |

1.0 |

|

UVC-150-36 |

220-280 |

150 |

36 |

5400 |

DN200 |

1.0 |

|

UVC-150-40 |

280-300 |

150 |

40 |

6000 |

DN250 |

1.0 |

Products Show

Packaging & Shipping