Product

Contact Us

Description: Ultraviolet UV System Submersible UV System Open Channel UV System

Ultraviolet UV System

UV systems are a globally accepted solution for water disinfection due to being a chemical-free sustainable solution, combined with being able of inactivating bacteria, viruses, and protozoa, which makes the technology vital for the future of water disinfection.

Disinfecting water with UV systems is a very straightforward, yet extremely efficient method to ensure disinfected water.

The water flows through the piping system and through the UV chamber. In this chamber, the water is exposed to ultraviolet light, that is emitted from the UV lamps. The UV light from the lamps has a specific wavelength in the UV-C spectrum (around 254nm), that enables microorganism inactivation if exposed with the right intensity.

In technical terms, when the water comes into contact with UV light, the chemical bonds are broken down, which changes the DNA structure. It is this change in the DNA structure that disables the pathogens’ ability to perform vital cellular functions, including reproducing or causing infection.

Bacteria such as E. coli reproduce extremely rapidly. This is where the UV lamps come into action to damage the DNA or RNA of the microorganisms, which disrupts their ability to function and replicate.

Ultraviolet UV System Benefits

A lower carbon footprint in comparison to alternative disinfection methods

Low maintenance, administration, and OPEX costs

No dangerous chemicals involved (storage, handling, and residuals)

No by-products being created in the disinfection process

No change in the water properties such as pH and temperature

Instant treatment with no processing time

Simple and safe implementation

It is especially a beneficial alternative to chlorine disinfection, which can potentially result in health complications such as respiratory diseases, as well as being incapable of inactivating Cryptosporidium and Giardia.

Applications

|

TOC reduction Chlorine destruction Food & Beverage Life Sciences ... |

Microelectronics Disinfection Ozone destruction Chlorine/Chloramine destruction ... |

Aquaculture Marine Microelectronics Recreational Water ... |

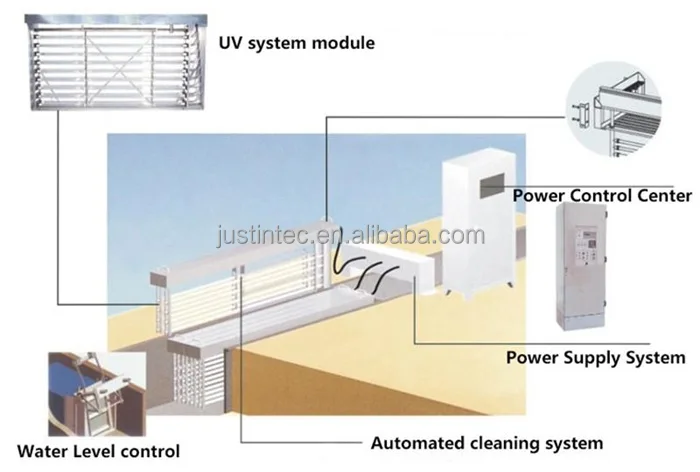

Open Channel Ultraviolet UV System

The Open Channel UV System is designed for municipal and industrial wastewater disinfection and treatment. Using long life hour life UV lamps, arranged in multiple optimised columns maximises the UV exposure to wastewater flow undergoing treatment.

The Open Channel UV system is of stainless steel construction and customisable to suit almost any application. Because the banks of lamps are modular, this allows for different depth and width configurations within your open channel installation. The versatility of the UV system makes it ideal for replacing and retrofitting existing water treatment processes, such as old chlorination tanks. The open channel UV system is also available in an inclined configuration – this provides a variety of extra options for depth, making the Open Channel UV system an adaptable and scalable option for wastewater disinfection treatment.

For ease of maintenance all Open Channel UV disinfection systems feature a sealed top compartment which houses access for the UV lamps, quartz sleeves, wiper motor and sensors. This means in-situ maintenance causes as little disruption as possible, making procedures quick, easy and hygienic while the system remains in place in the open channel.

Automated wipers regularly clean the quartz sleeves and UV sensor to maintain a consistent level of disinfection and monitoring, the bespoke brush heads maintain the efficiency of the lamps by cleaning the quartz sleeves to maximise the lamp UV-C output.

|

Lamps |

Low-pressure, high-output (LPHO) amalgam |

|

Rack Configuration |

2 to 8 lamps per rack |

|

Ballasts |

Electronic, variable output (60-100%), pre-heat start to extend lamp life |

|

Power Demand |

325 watts/lamp including ballast (nominal) |

|

Power Input |

110-480VAC, single Phase or 3 Phase,50Hz or 60 Hz |

|

Environment |

Indoor or Outdoor, 10 to 109°F (12 to 43°C) ambient, <95% relative humidity (non-condensing) |

|

Level Control |

Fixed tubular weir or serpentine or motorized weir gate to maintain correct water level |

|

System Controls |

Microprocessor based closed loop control |

|

Channel |

Stainless construction |

|

Instrumentation |

UV sensor, level monitor |

|

Options |

Automated cleaning |

Products Show