Product

Contact Us

PES Hollow Fiber UF Membrane

Hollow Fiber UF Membrane Introduction

Ultrafiltration membrane belongs to capillary hollow fiber membrane,It is a polymer material membrane,It is a separation product without phase change.With the material of modified PVDF and PES, It has good water permeability, mechanical properties, chemical resistance and pollution resistance. The Module type is Outside-in(PVDF) and Inside-out(PES). It can filter various harmful substances such as bacteria, colloids, suspended solids and microorganisms which are in the feed water.

Hollow Fiber UF Membrane Application

Water Treatment:

sterilization, turbidity removal and purification of tap water, groundwater and surface water; pretreatment of reverse osmosis.

Wastewater Treatment and Reuse:

urban reclaimed water reuse, industrial wastewater treatment and reuse, hospital wastewater, and treatment of oilfield reinjection water.

Seawater Desalination:

seawater purification and seawater desalination pretreatment.

Medicine and Biotechnology:

separation and refinement of traditional Chinese medicine extracts, depyrogenation of medical sterile water and water for injection, separation and purification of biological products, and blood purification.

Food and Cooking Materials:

clarification of fruit and vegetable juices and wine, filtration and sterilization of milk, concentration and purification of whey.

Hollow Fiber Membrane Material

The hollow fiber materials are polyvinylidene (PVDF) and polyvinyl alcohol (PES), these materials have the following characteristics:

The microstructure of the hollow fiber membrane is a sponge structure and the pores change in gradient, which is stronger than the traditional finger-shaped pore structure and has stronger anti-pollution ability.

Good hydrophilicity, uniform membrane pore size, and large water permeability per unit area.

Good heat resistance, strong chemical stability, good resistance to chemical cleaning.

It operates under ultra-low pressure and has low energy consumption.

PES Hollow Fiber UF Membrane Technical Data

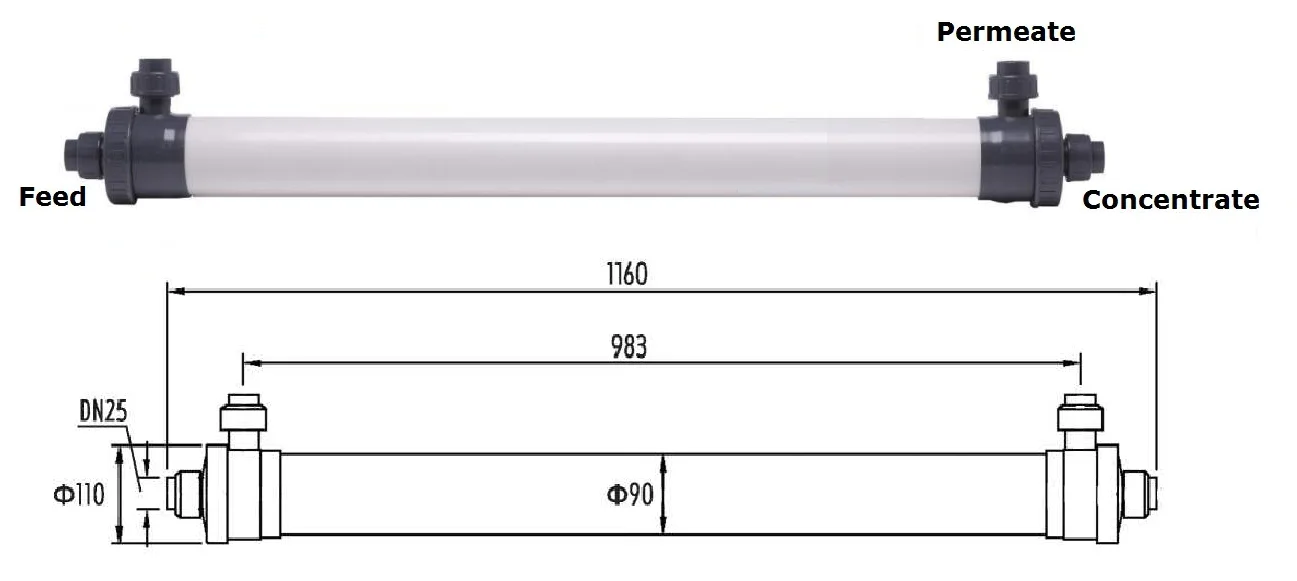

HC-UF90-PES UF Membrane

|

Model |

HC-UF90-PES |

|

Structure |

Inside-out |

|

Material |

PES |

|

Membrane Filter Precision (Dalton) |

6,000 20,000 65,000 150,000 200,000(0.1μm) 0.2μm 0.45μm 0.65μm |

|

Membrane Area |

4.5m2 |

|

Hollow Fiber Diameter ID/OD (mm) |

0.6/1.0 0.8/1.4 0.9/1.5 1.0/1.6 1.5/2.5 1.7/2.5 3.0/4.0 |

|

Size |

φ90mm×1160mm |

|

Port Size |

DN25 |

|

Pure Water Flux |

1,350L/H (0.15MPa,25℃) |

|

Design Flux |

160~450L/M2.H (0.15MPa,25℃) |

|

Flux Range |

260~780L/H (0.15MPa,25℃) |

|

Suggested Working Pressure |

≤0.2MPa |

|

Max.Water Inlet Pressure Pressure |

0.3MPa |

|

Max.Transmembrane Pressure |

0.2MPa |

|

Working Temperature |

5~45ºC |

|

pH Range |

Working: 4~10; Washing: 2~12 |

|

Operation Mode |

Cross-flow or Dead-end |

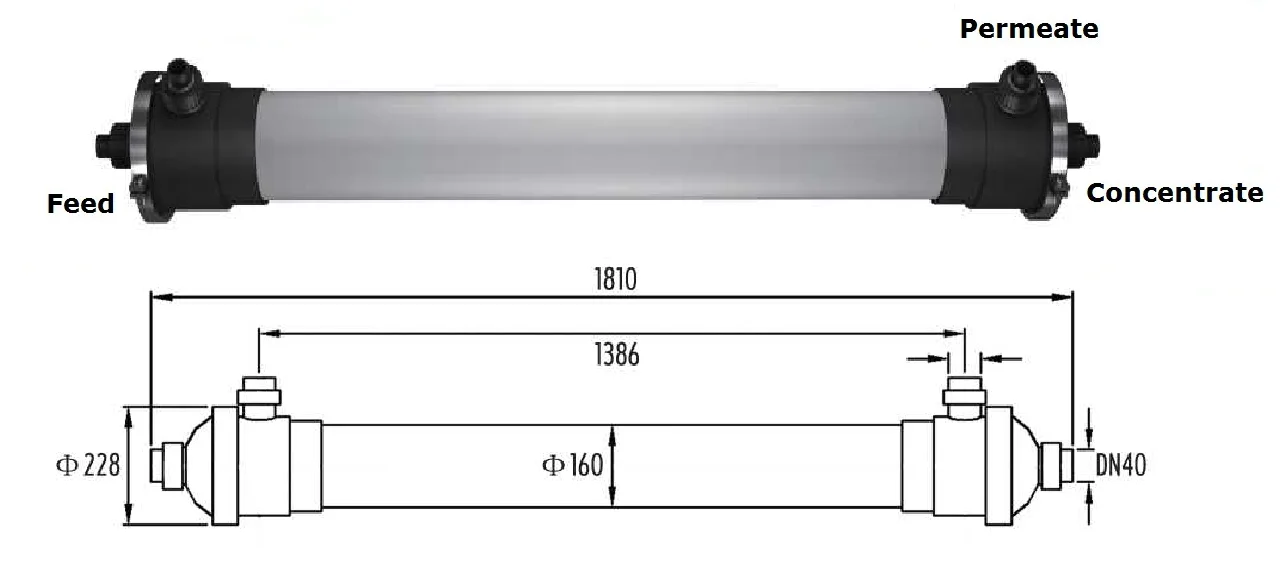

HC-UF160-PES UF Membrane

|

Model |

HC-UF160-PES |

|

Structure |

Inside-out |

|

Material |

PES |

|

Membrane Filter Precision (Dalton) |

6,000 20,000 65,000 150,000 200,000(0.1μm) 0.2μm 0.45μm 0.65μm |

|

Membrane Area |

20m2 |

|

Hollow Fiber Diameter ID/OD (mm) |

0.6/1.0 0.8/1.4 0.9/1.5 1.0/1.6 1.5/2.5 1.7/2.5 3.0/4.0 |

|

Size |

φ160mm×1810mm |

|

Port Size |

DN40 |

|

Pure Water Flux |

6,000L/H (0.15MPa,25℃) |

|

Design Flux |

35~100L/M2.H (0.15MPa,25℃) |

|

Flux Range |

700~2,000L/H (0.15MPa,25℃) |

|

Suggested Working Pressure |

≤0.2MPa |

|

Max.Water Inlet Pressure Pressure |

0.3MPa |

|

Max.Transmembrane Pressure |

0.2MPa |

|

Working Temperature |

5~45ºC |

|

pH Range |

Working: 4~10; Washing: 2~12 |

|

Operation Mode |

Cross-flow or Dead-end |

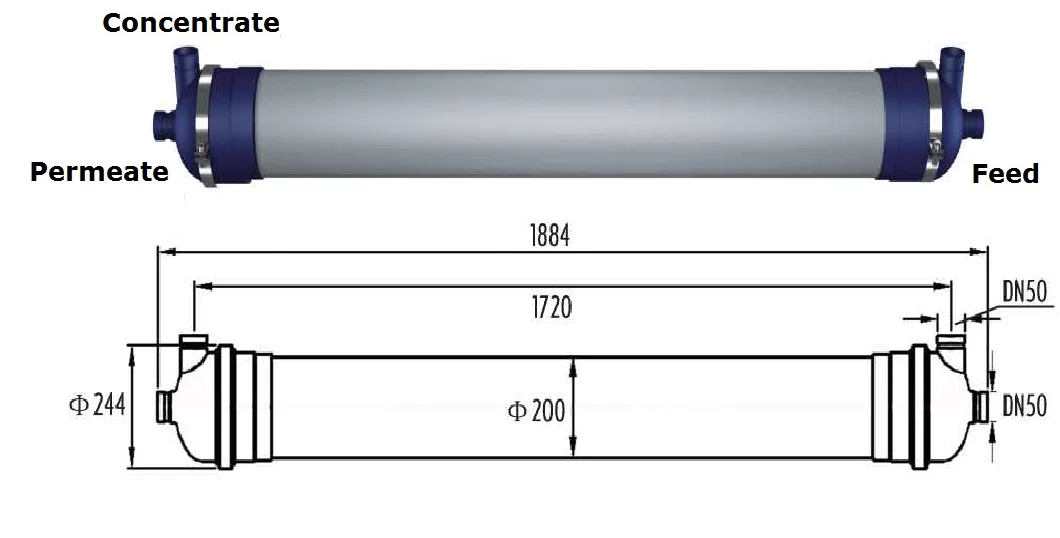

HC-UF200-PES UF Membrane

|

Model |

HC-UF200-PES |

|

Structure |

Inside-out |

|

Material |

PES |

|

Membrane Filter Precision (Dalton) |

6,000 20,000 65,000 150,000 200,000(0.1μm) 0.2μm 0.45μm 0.65μm |

|

Membrane Area |

40m2 |

|

Hollow Fiber Diameter ID/OD (mm) |

0.6/1.0 0.8/1.4 0.9/1.5 1.0/1.6 1.5/2.5 1.7/2.5 3.0/4.0 |

|

Size |

φ200mm×1884mm |

|

Port Size |

DN50 |

|

Pure Water Flux |

12,000L/H (0.15MPa,25℃) |

|

Design Flux |

35~100L/M2.H (0.15MPa,25℃) |

|

Flux Range |

1,400~4,000L/H (0.15MPa,25℃) |

|

Suggested Working Pressure |

≤0.2MPa |

|

Max.Water Inlet Pressure Pressure |

0.3MPa |

|

Max.Transmembrane Pressure |

0.15MPa |

|

Working Temperature |

5~45ºC |

|

pH Range |

Working: 4~10; Washing: 2~12 |

|

Operation Mode |

Cross-flow or Dead-end |

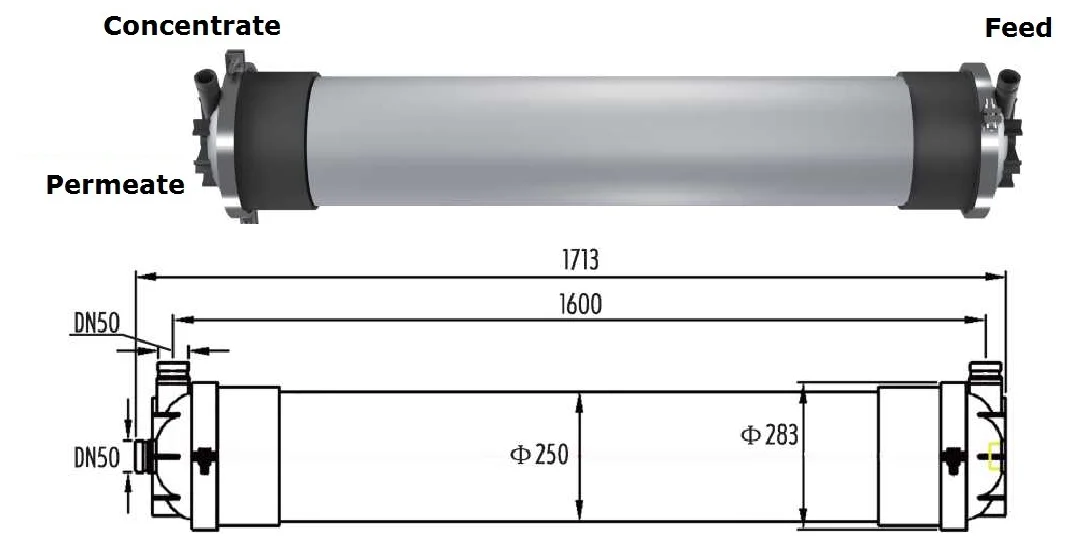

HC-UF250-PES UF Membrane

|

Model |

HC-UF250-PES |

|

Structure |

Inside-out |

|

Material |

PES |

|

Membrane Filter Precision (Dalton) |

6,000 20,000 65,000 150,000 200,000(0.1μm) 0.2μm 0.45μm 0.65μm |

|

Membrane Area |

50m2 |

|

Hollow Fiber Diameter ID/OD (mm) |

0.6/1.0 0.8/1.4 0.9/1.5 1.0/1.6 1.5/2.5 1.7/2.5 3.0/4.0 |

|

Size |

φ250mm×1713mm |

|

Port Size |

DN50 |

|

Pure Water Flux |

15,000L/H (0.15MPa,25℃) |

|

Design Flux |

35~100L/M2.H (0.15MPa,25℃) |

|

Flux Range |

1,750~5,000L/H (0.15MPa,25℃) |

|

Suggested Working Pressure |

≤0.2MPa |

|

Max.Water Inlet Pressure Pressure |

0.3MPa |

|

Max.Transmembrane Pressure |

0.15MPa |

|

Working Temperature |

5~45ºC |

|

pH Range |

Working: 4~10; Washing: 2~12 |

|

Operation Mode |

Cross-flow or Dead-end |

Replacement Size

|

Model |

Membrane Material |

Membrane Area |

Size |

|

UF-1860C-PES |

PES |

40 m2 |

φ200mm×1527.5mm |

|

UF-1860X-PES |

40 m2 |

φ200mm×1537mm |

|

|

UF-1860H-PES |

55 m2 |

φ219mm×1537.5mm |

|

|

UF-1060-PES |

46 m2 |

φ250mm×1710mm |

|

|

UF-1240-PES |

55 m2 |

φ315mm×1302mm |

Parts Material

|

Parts |

Material |

|

Hollow fiber |

PES |

|

Sealing |

Epoxy Resin |

|

Shell |

UPVC |

Typical Operating Parameters

|

Maximum backwash pressure |

0.15MPa |

|

Backwash flux |

100~150L/m2.h |

|

Backwash frequency |

Once every 30-60 minutes |

|

Backwash time |

30-60 second each time |

|

Dosing backwash frequency |

0~4 times/day |

|

Dosing backwash time |

5-10 minutes each time |

|

Chemical cleaning frequency |

Once every 1~3 months |

Common cleaning chemicals:

|

Sterilization |

15ppm Sodium hypochlorite |

|

Organic pollution cleaning |

0.2% Sodium hypochlorite + 0.1% Sodium hydroxide |

|

Inorganic pollution cleaning |

1~2% Citric acid/0.2% hydrochloric acid |

Feed Water Requirements:

Before the water entering the UF membrane, it should have a pre-treatment. Such as the PP filter(less than 50 micron)

The feed water can’t include the organic solvents!

|

Feed water turbidity |

≤25NTU |

|

Grease content |

≤2mg/L |

|

Influent suspended solids |

≤20mg/L |

|

Total iron content |

≤1mg/L |

|

Continuous influent residual chlorine |

≤5ppm |

|

COD |

≤500mg/L |

Water Production Performance

|

Ingredients in water |

Filter effect |

|

Suspended Matter, Particle>1μm |

Removal Rate ≥99% |

|

SDI |

Production Water ≤3 |

|

Virus, Bacteria |

>4 log |

|

Turbidity |

Production Water <0.1NTU |

|

TOC |

Removal Rate 0-25% |

Product Show