Product

Contact Us

Reverse Osmosis RO Membrane

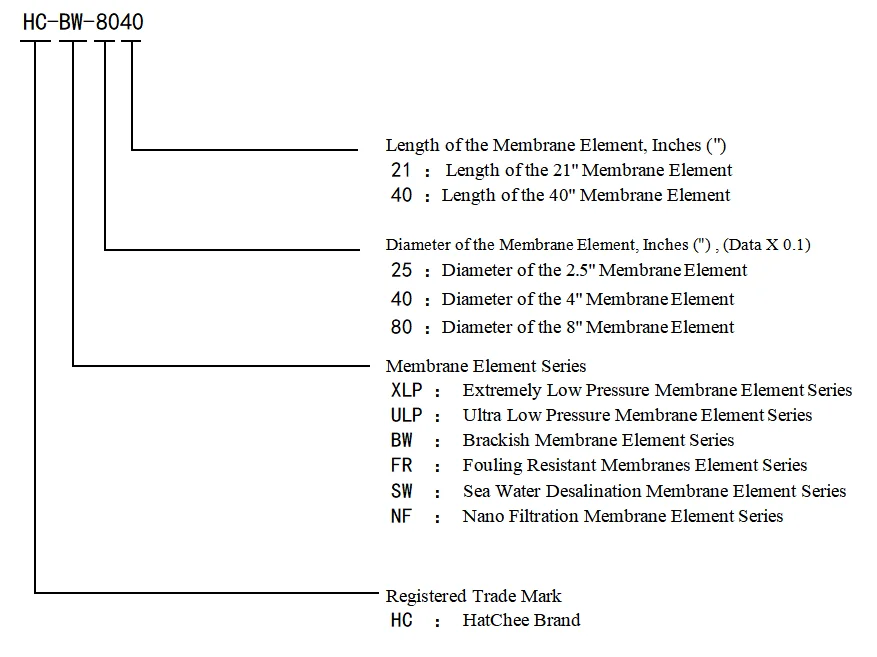

Reverse Osmosis RO Membrane Naming Rule

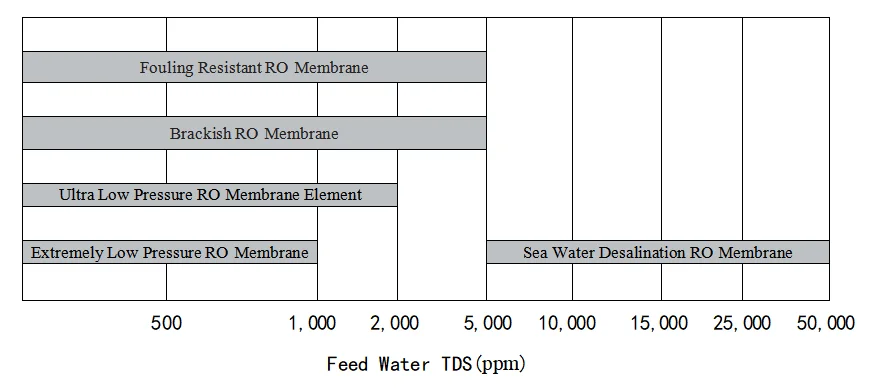

Reverse Osmosis RO Membrane Selecting Guide

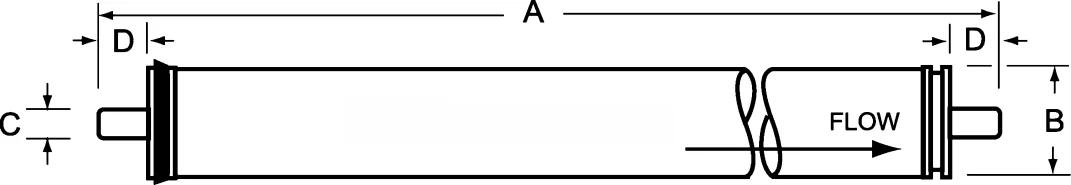

Reverse Osmosis RO Membrane Dimension

2521 2540 4021 4040 Element:

|

Model |

A/mm(inch) |

B/mm(inch) |

C/mm(inch) |

D/mm(inch) |

|

4021 |

533.4 (21) |

99.7 (3.9) |

19.1 (0.75) |

26.7 (1.05) |

|

4040 |

1016.0 (40) |

99.7 (3.9) |

19.1 (0.75) |

26.7 (1.05) |

|

2521 |

533.4 (21) |

61 (2.4) |

19.1 (0.75) |

30.2 (1.19) |

|

2540 |

1016.0 (40) |

61 (2.4) |

19.1 (0.75) |

30.2 (1.19) |

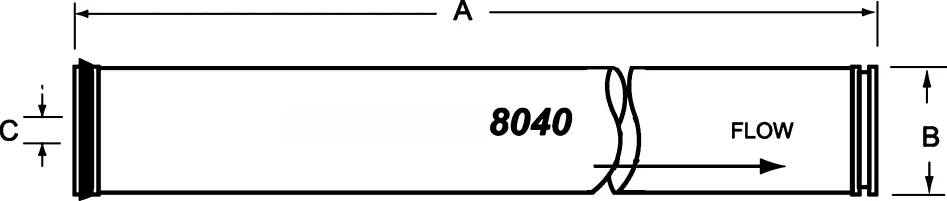

8040 Element:

|

Model |

A/mm(inch) |

B/mm(inch) |

C/mm(inch) |

|

8040 |

1016 (40) |

201 (7.9) |

29 (1.125) |

Reverse Osmosis Membrane Elements Technical Data

NF Series Membrane Elements

NF Series of nanofiltration membrane elements can achieve high permeate water and excellent desalination performance. Therefore, it is suitable for large-scale industrial and municipal water treatment systems. In use, it shows excellent ability to remove pesticides, viruses and bacteria. It has high ability to remove natural organic substances and medium ability to remove total hardness. Through innovative technology, the product has a stronger film surface, strong anti-oxidation performance, and the use of ultra- low pressure mode of operation can significantly improve the system and operation economy.

NF series of membrane elements performance:

|

Model |

Active Membrane ft2(m2) |

Average Permeate GPD(m3/d) |

Stable Rejection % |

|

|

HC-NF60-4040 |

85(7.9) |

2000(7.5) |

60±10 |

500 NaCl |

|

≥97 |

2000 MgO4 |

|||

|

HC-NF60-8040 |

400(37.2) |

10000(37.9) |

60±10 |

500 NaCl |

|

≥97 |

2000 MgO4 |

|||

|

HC-NF90-4040 |

85(7.9) |

1800(6.8) |

90±10 |

500 NaCl |

|

≥98 |

2000 MgO4 |

|||

|

HC-NF90-8040 |

400(37.2) |

9000(34.1) |

90±10 |

500 NaCl |

|

≥98 |

2000 MgO4 |

|||

NF series of membrane elements Testing Conditions:

Testing Pressure:70 psi (0.48MPa)

Temperature of Testing Solution:25 ℃

Concentration of Testing Solution:500ppm NaCl;2000ppm MgSO4

pH Value of Testing Solution:8

Recovery Rate of Single Element:15%

NF series of membrane elements Operation Limits & Conditions:

Max.Working Pressure:600psi(4.14MPa)

Max.Feed Water Flow:75gpm(17 m3/h) for 8040; 16gpm(3.6 m3/h) for 4040,4021; 6.0gpm(1.4 m3/h) for 2521,2540

Max.Feed Water Temperature: 45℃

Max.Mn: 0.1mg/L

Max.Fe: 0.05mg/L

Max.Turbidity NTU: 1.0

Max.Feed Water SDI15: 5

Max.Feed Water COD: 15ppm

Max.Feed Water BOD: 10ppm

Max.Feed Water TOC: 3ppm

Residual Chlorine Concentration of Feed Water: <0.1ppm

pH Range of Feed Water During Continuous Operation: 3~10

Max.Pressure Drop of Single Element: 15psi(0.1MPa) for 8040,4040,2540; 10psi(0.07MPa) for 2521,4021

Note:

1.For the recommended design scope, please refer to the latest version of the technical manual, design guide, or consult with membrane technology experts. If the user does not strictly follow the operating conditions provided by the sample, Tianjin Justin Technology Co., Ltd will not bear all the consequences arising therefrom.

2.The average water yield listed in the table shows that the error of water yield of single membrane element in series is within (+10%). The difference between the minimum water yield and the nominal value of other series of single membrane elements is not more than 20% of the nominal value.

3.Wet membrane components are strictly tested before they leave the factory. They are stored in 1.0% sodium bisulfite solution. Then they are packed in vacuum and packed in cardboard boxes. The safe storage temperature of wet membrane components is 4-45℃.

4.RO production water to be discharged in the first hour of operation.

5.During storage and operation, it is prohibited to add any chemicals that affect membrane components. In case of violating the use of such chemicals, Tianjin Justin Technology Co., Ltd will not bear all the consequences arising therefrom.

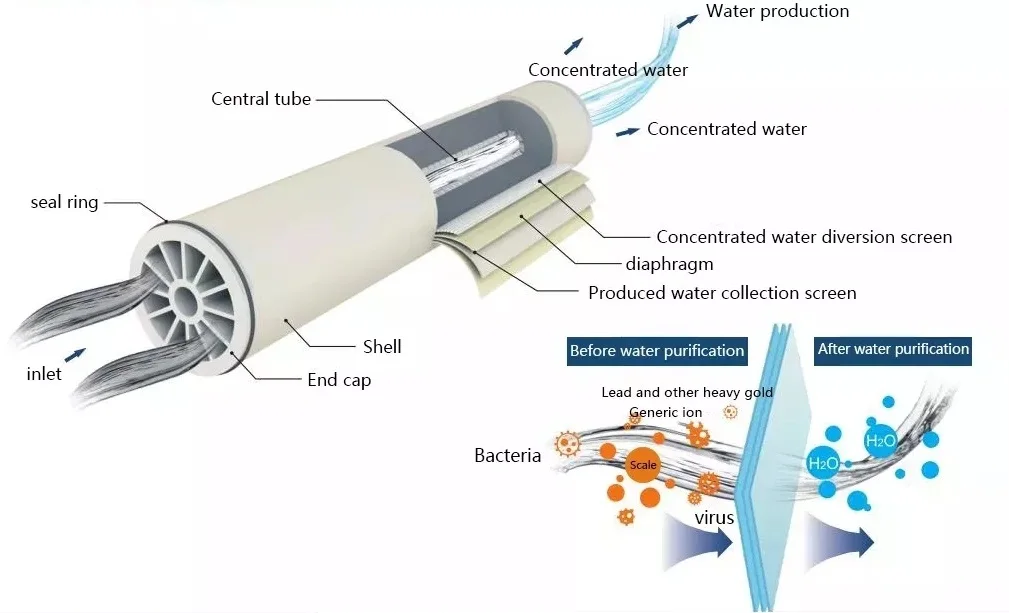

Product Show