Product

Contact Us

Electrodization EDI Module

Working principle

EDI(Electrodization) is a membrane separation technology which combines electrodialysis and ion exchange technology, including anion exchange membrane and ion exchange membrane.Switching resin and DC power supply lamp equipment to realize water under the action of electric field through the selection of ion exchange membrane and resin exchange of ions Directional migration of ions to remove salt in water depth and to exchange ion exchange resin for two consecutive years through H and OH produced by water electrolysis. Prod action of Super pure water up to 15-18.2 Omega cm.

Product characteristics

Using the technology of middle partition full fill, good water quality

It is easy to operate without salt and heavy water circulation

Excellent electrical performance, high current efficiency, low voltage, low energy consumption

Line the lines side by side, two entry and two out of standard thread excuse, easy to install

Perfect structural design to ensure zero leakage

Product application

Boiler feed water for power, chemical and metallurgical industries

Super pure water for electronics, semiconductors and precision machinery

Water for chemical processes

Medical water

Ultrapure lab water

Main performance parameters

EDI-Access Parameters

| RS-10 | 10L/H |

| RS-15 | 15L/H |

| RS-20 | 20L/H |

| RS-30 | 30L/H |

| RM-50 | 50L/H |

| RM-100 | 100L/H |

| RM-150 | 150L/H |

| RM-200 | 200L/H |

| RM-250 | 250L/H |

| RM-300 | 300L/H |

|

The amount of water produced |

LX-50 |

LX-100 |

LX-200 |

LX-300 |

LX-500 |

|

Water production flow range(m3/h) |

0.5-0.7 |

0.7-1.2 |

1.5-2.5 |

2.0-3.5 |

3.5-5.5 |

|

Standard water flow(m3/h) |

0.5 |

1 |

2 |

3 |

5 |

|

Hydropower resistance(MQ.cm) |

>15 |

>15 |

>15 |

>15 |

>15 |

|

Silicon boron removal rate(%) |

≥99 |

≥99 |

≥99 |

≥99 |

≥99 |

EDI-Inflow parameters

|

Inflow requirements |

LX-50 |

LX-100 |

LX-200 |

LX-300 |

LX-500 |

|

Temperature range (℃) |

15-35 (25 optimal) |

15-35 (25 optimal) |

15-35 (25 optimal) |

15-35 (25 optimal) |

15-35 (25 optimal) |

|

Inflow PH |

6.5-9.0 |

6.5-9.0 |

6.5-9.0 |

6.5-9.0 |

6.5-9.0 |

|

Electric conductivity (μ S/cm) |

1-25 (optimal<5) |

1-25 (optimal<5) |

1-25 (optimal<5) |

1-25 (optimal<5) |

1 -25 (optimal<5) |

|

Total carbon dioxide (ppm) |

<3 (optimal<2) |

<3 (optimal<2) |

<3 (optimal<2) |

<3 (optimal<2) |

<3 (optimal<2) |

|

Total hardness (ppm) |

<1 |

<1 |

<1 |

<1 |

<1 |

|

Siliconactive silica (ppm) |

≤0.5 (optimal≤0.2) |

≤0.5 (optimal≤0.2) |

≤0.5 (optimal≤0.2) |

≤0.5 (optimal≤0.2) |

≤0.5 (optimal≤0.2) |

|

Total organic carbon (ppm) |

≤0.5 |

≤0.5 |

≤0.5 |

≤0.5 |

≤0.5 |

|

Residual chlorine (ppm) |

≤0.05 |

≤0.05 |

≤0.05 |

≤0.05 |

≤0.05 |

|

Metal ion (Fe/Mn.ppm) |

≤0.01 |

≤0.01 |

≤0.01 |

≤0.01 |

≤0.01 |

|

Turbidity (NTU) |

<1 |

<1 |

<1 |

<1 |

<1 |

|

Lipid |

Not detected |

Not detected |

Not detected |

Not detected |

Not detected |

|

PM(um) |

≤1.0 (optimal≤0.5) |

≤1.0 (optimal≤0.5) |

≤1.0 (optimal≤0.5) |

≤1.0 (optimal≤0.5) |

≤1.0 (optimal≤0.5) |

|

Oxidant |

Not detected |

Not detected |

Not detected |

Not detected |

Not detected |

EDI Operating parameters

|

Operating parameters |

LX-50 |

LX-100 |

LX-200 |

LX-300 |

LX-500 |

|

Fresh water output pressure (Din, bar) |

1-5 |

1-5 |

1-5 |

1-5 |

1-5 |

|

Fresh water intake pressure (Cin, bar) |

0.5-1.0 lower than Din |

0.5-1.0 lower than Din |

0.5-1.0 lower than Din |

0.5-1.0 lower than Din |

0.5-1.0 lower than Din |

|

Fresh water output pressure (Dout, bar) |

0.5-2 |

0.5-2 |

0.5-2 |

0.5-2 |

0.5-2 |

|

Concentrated water output pressure (Cout, bar) |

0.5-1.0 lower than Dout |

0.5-1.0 lower than Dout |

0.5-1.0 lower than Dout |

0.5-1.Glower than Dout |

0.5-1.0 lower than Dout |

|

Working voltage (VDC) |

10-50 |

30-80 |

50-100 |

60-120 |

80-160 |

|

Running current (A) |

2-5 |

2-5 |

2-5 |

2-5 |

2-5 |

|

Recovery rate (%) |

85-95 |

85-95 |

85-95 |

85-95 |

85-95 |

|

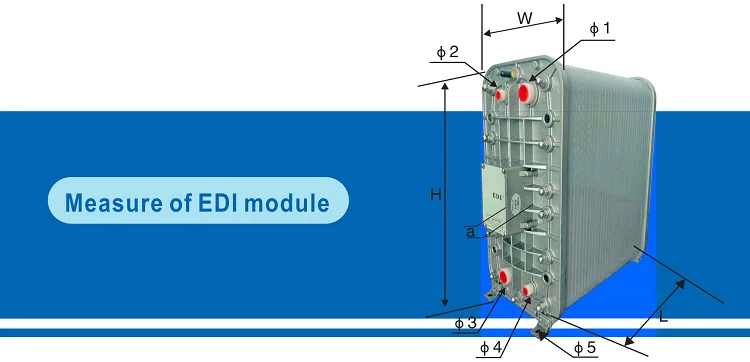

Item |

L |

W |

H |

φ1 |

φ2 |

φ3 |

φ4 |

φ5 |

a |

Hole site |

|

|

Length |

Width |

||||||||||

|

LX-50 |

325 |

320 |

610 |

BSP External thread 1-1/4" Fresh water inlet |

BSP External thread 3/4" Concentrated water inlet |

BSP External thread 1-1/4" Fresh water outlet

|

BSP External thread 3/4" Concentrated water outlet

|

M10 |

40 |

160 |

215 |

|

LX-100 |

400 |

320 |

610 |

235 |

215 |

||||||

|

LX-200 |

550 |

320 |

610 |

385 |

215 |

||||||

|

LX-300 |

700 |

320 |

610 |

535 |

215 |

||||||

|

LX-500 |

925 |

320 |

610 |

760 |

215 |

||||||

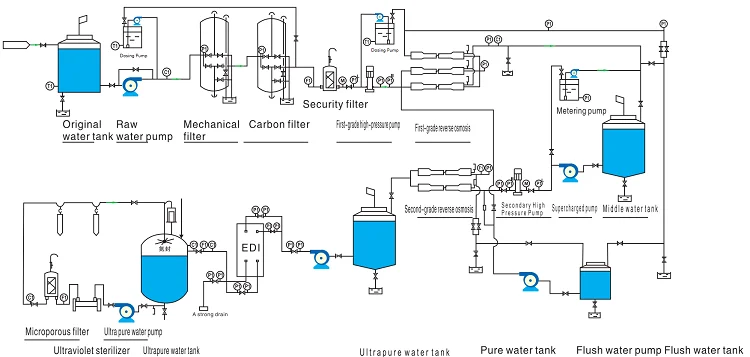

EDI Process Flow Diagram

Product Show