Product

Contact Us

Disc Tubu RO Membrane DTRO DTNF

Disk tubular RO/NF DTRO / DTNF

DTRO/DTNF Introduction

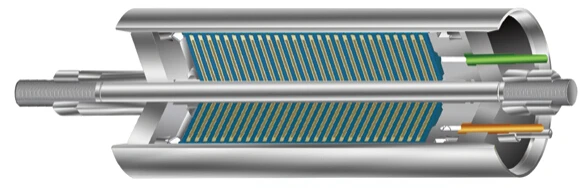

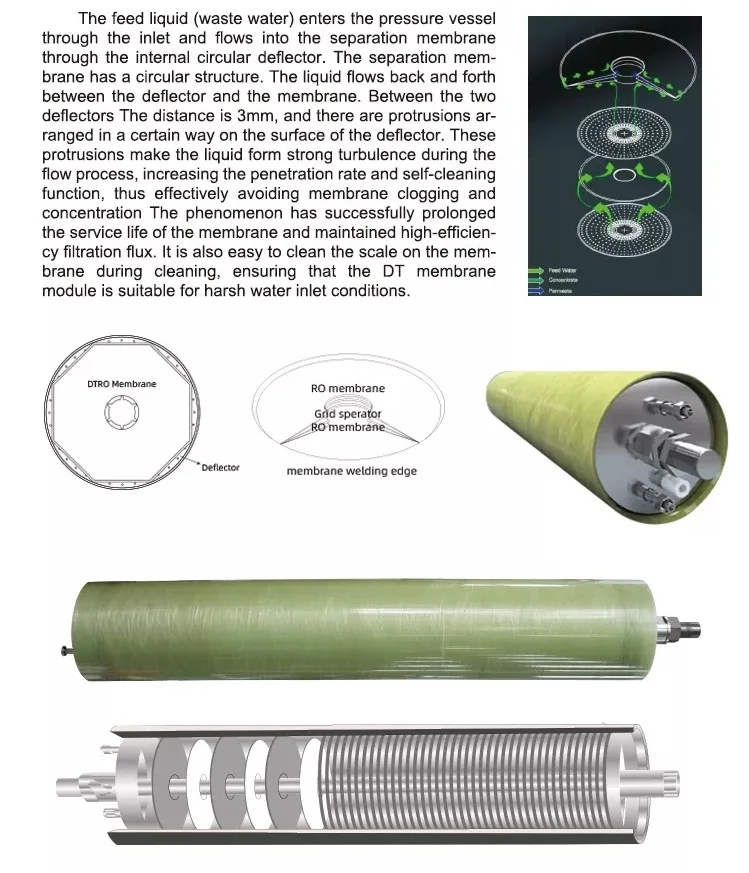

Disk tubular membrane technology referred to as DT, common for disk tubular RO(DTRO) and disk tubular (DTNF). The membrane module structure is distinct from the traditional spiral wound membrane.With open flow channels,feed flows through the entrance into the pressure vessel and reach the disk in a short distance. Then the feed flows 180 degrees from one side of the membrane reverse flow into the other side of the membrane,into the next disk again and finally runoff from outlet.The special design makes feed collide with the disk bulge through the membrane surface forming turbulence which increases flow rate and self-cleaning function and long service life of the membrane.

Features

High strength design, up to 120 bar operating pressure

Open disk with low flow resistance and concentration polarization

High pressure resistance and salt rejection membrane

Applications

Landfill leachate

High concentration of industrial wastewater

Spiral wound RO/NF concentrates

Industrial high salts water

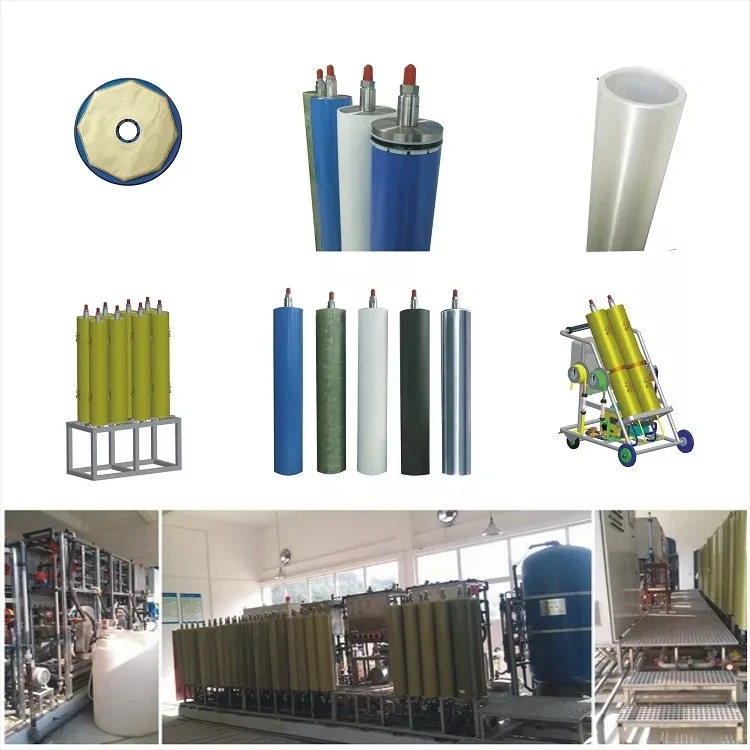

DTRO/DTNF module

DTRO/DTNF Membrane

Disk

SUS center link

High pressure vessel

Inlet and outlet pipe and accessories

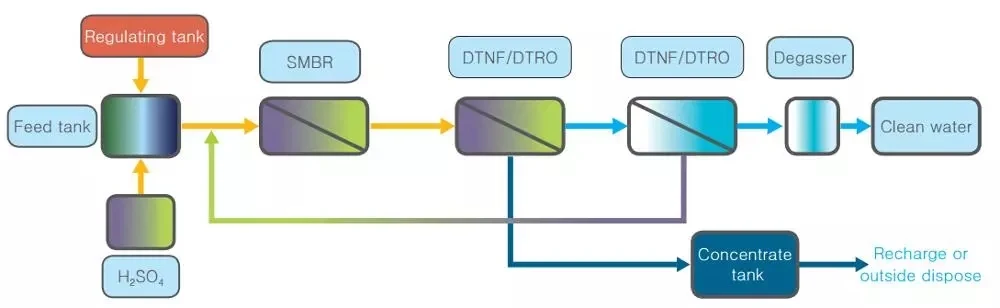

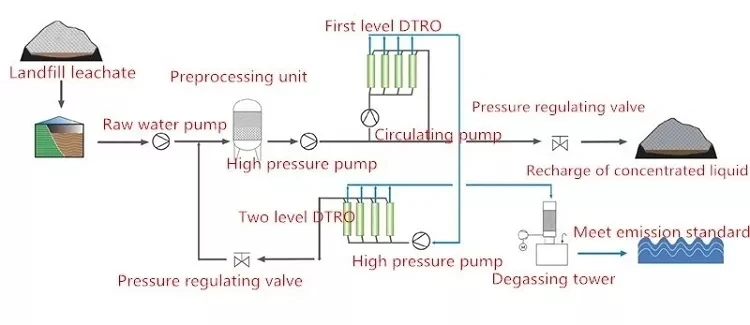

A typical process diagram

DTRO/DTNF Specifications

|

Items |

High pressure |

High pressure |

Super high pressure |

|

Mode |

DTRO-1 |

DTNF-1 |

DTRO-2 |

|

Membrane material |

Composite Polyamide |

Composite Polyamide |

Composite Polyamide |

|

Disk qty. (pc) |

209 |

209 |

209 |

|

Rejection (%) |

99 |

97 |

99 |

|

Membrane effective area (m2) |

9.4 |

9.4 |

9.4 |

|

Feed flux (l/h) |

500-1200 |

500-1200 |

500-1000 |

|

Permeate flux range (l/h) |

8-40 |

8-40 |

8-35 |

|

Disk material |

ABS |

ABS |

ABS |

|

Vessel materia |

Fiberglass |

Fiberglass |

Fiberglass/SUS |

|

Operation pressure (bar) |

75 |

75 |

120 |

|

Max. TMP (bar) |

9 |

9 |

9 |

|

Max. operation temperature (℃) |

40 |

40 |

40 |

|

Chlorine tolerance (ppm) |

<0.1 |

<0.1 |

<0.1 |

|

Recommended operation pH |

6-9 |

6-9 |

6-9 |

|

Chemical cleaning pH@40℃ |

2-11 |

2-11 |

2-11 |

Note:

Performance data above is the nominal value.

The actual permeate flux of individual module may be in ±15% range.

Test condition:

RO: NaCl 32,000mg/L@800psi.

NF: MgSO4 30,000mg/L@600psi.

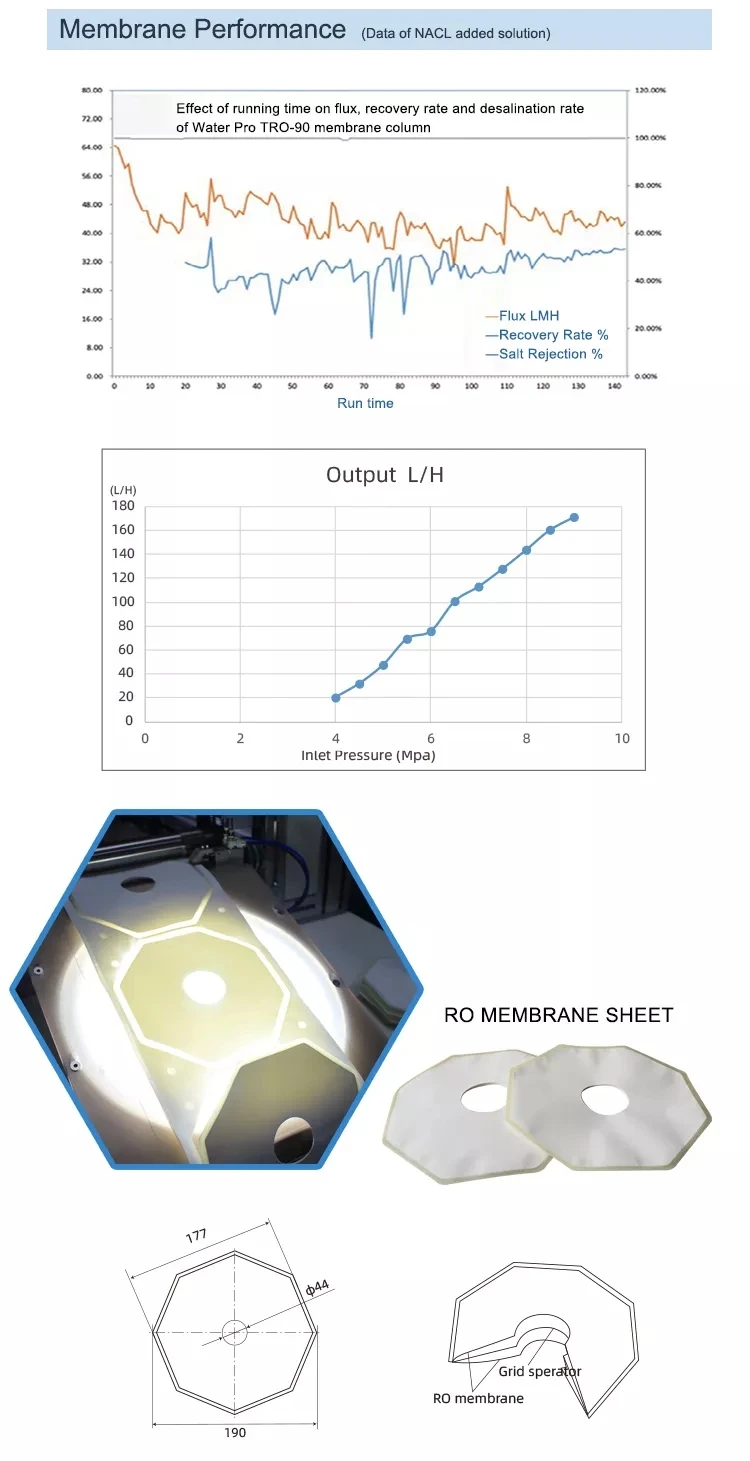

DTRO High Pressure Disc Tubu RO Membrane Element

Application:

Lanfill leachate and other high TSS waste water

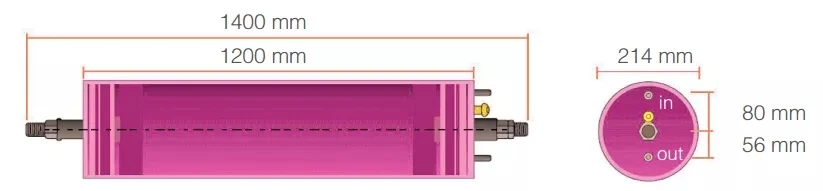

DTRO Membrane Element Dimensions

DTRO-1 size is 216mm, DTRO-2 size is 220mm.

DTRO Membrane Element Specifications:

|

Model |

DTRO-1 |

DTRO-2 |

|

Membrane type |

BW type |

SW type |

|

Membrane material |

Polyamide composite |

Polyamide composite |

|

Membrane cushion qty.(pc) |

209 |

209 |

|

Membrane element structure |

Disc tube with GRP vessel |

Disc tube with GRP vessel |

|

Membrane effective area |

9.4m2 (101ft2) |

9.4m2 (101ft2) |

|

Rejection(%) * |

98 |

99 |

|

Lowest rejection(%) |

95 |

98 |

|

Feed flow( l/h) |

500-1000 l/h |

500-1000 l/h |

|

Permeate flow( l/h) |

80-450 l/h |

80-350 l/h |

|

Disc material |

ABS |

ABS |

|

Max. feed side pressure drop: |

9bar |

9bar |

|

Max. feed side operation pressure |

75bar |

90bar |

|

Max. operating temperature: |

40℃ |

40℃ |

|

Allowable pH – continuous operation: |

6-9 |

6-9 |

|

Allowable pH – short term cleaning @40℃ range |

2-12 |

2-12 |

|

Free chlorine tolerance |

≤0.1ppm |

≤0.1ppm |

|

Water inlet and outlet connection (mm) |

12 swagelock |

12 swagelock |

|

Permeate connection (mm) |

9 coupling hose pipe |

9 coupling hose pipe |

Note:

Performance data above is the normal value.

The actual permeate flux of individual module may be in ±15% range.

Test conditions:

RO: NaCl 32,000.mg/L @55.2 bar.

DTRO Super High Pressure Disc Tubu RO Membrane Element

Application:

Lanfill leachate and other high TSS waste water

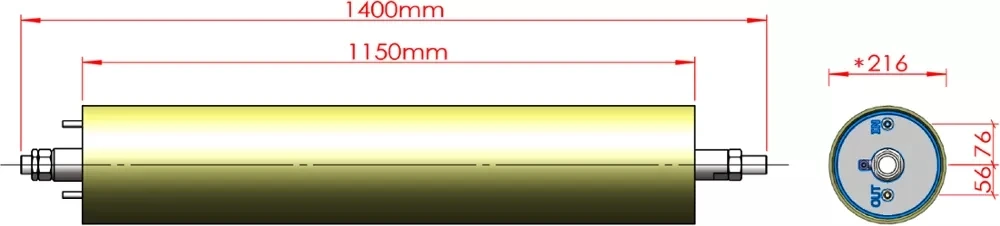

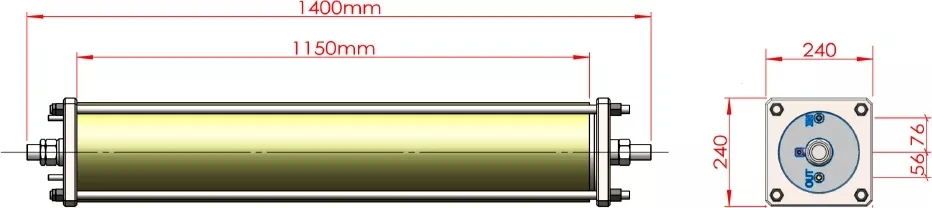

DTRO Membrane Element Dimensions

DTRO Membrane Element Specifications:

|

Model |

DTRO-H1 |

DTRO-H2 |

|

Membrane type |

SW type |

SW type |

|

Membrane material |

Polyamide composite |

Polyamide composite |

|

Membrane cushion qty.(pc) |

209 |

209 |

|

Membrane element structure |

Disc tube with GRP vessel |

Disc tube with GRP vessel |

|

Membrane effective area |

9.4m2 (101ft2) |

9.4m2 (101ft2) |

|

Rejection(%) * |

99 |

99 |

|

Lowest rejection(%) |

98 |

98 |

|

Feed flow( l/h) |

500-1000 l/h |

500-1000 l/h |

|

Permeate flow( l/h) |

80-350 l/h |

80-280 l/h |

|

Disc material |

ABS |

ABS |

|

Max. feed side pressure drop: |

9bar |

9bar |

|

Max. feed side operation pressure |

120bar |

160bar |

|

Max. operating temperature: |

40℃ |

40℃ |

|

Allowable pH – continuous operation: |

6-9 |

6-9 |

|

Allowable pH – short term cleaning @40℃ range |

2-12 |

2-12 |

|

Free chlorine tolerance |

≤0.1ppm |

≤0.1ppm |

|

Water inlet and outlet connection (mm) |

12 swagelock |

12 swagelock |

|

Permeate connection (mm) |

9 (hosepipe connection) |

9 (hosepipe connection) |

Note:

Performance data above is the normal value.

The actual permeate flux of individual module may be in ±15% range.

Test conditions:

RO: NaCl 32,000.mg/L @55.2 bar.

Product Show