Product

联系信息

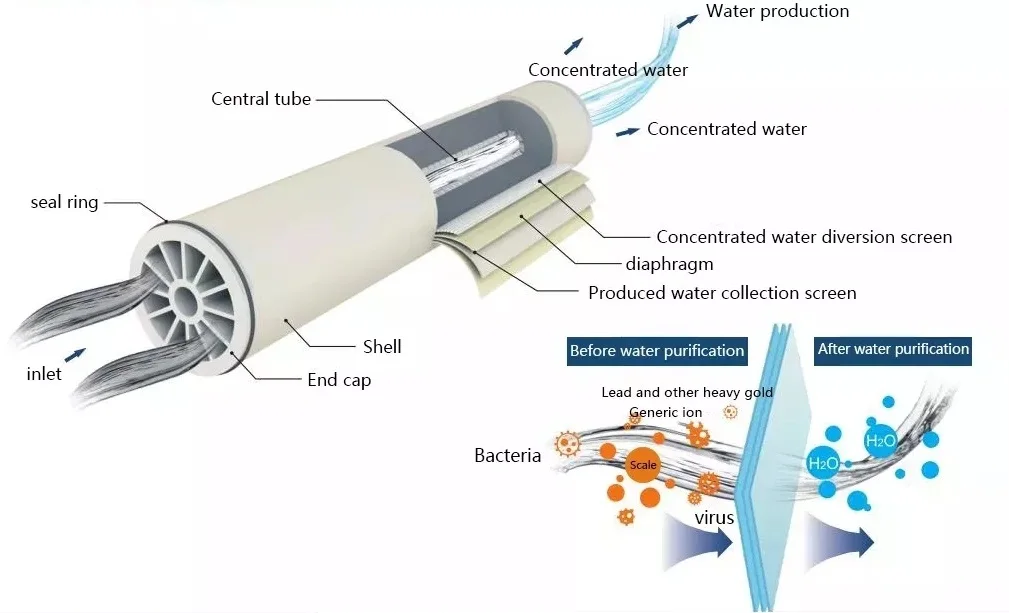

Reverse Osmosis RO Membrane

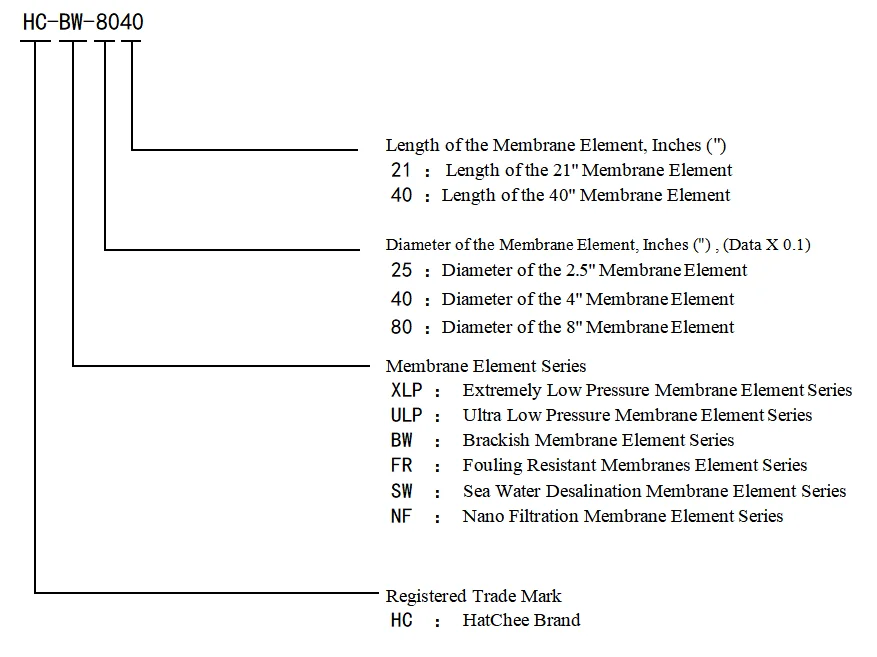

Reverse Osmosis RO Membrane Naming Rule

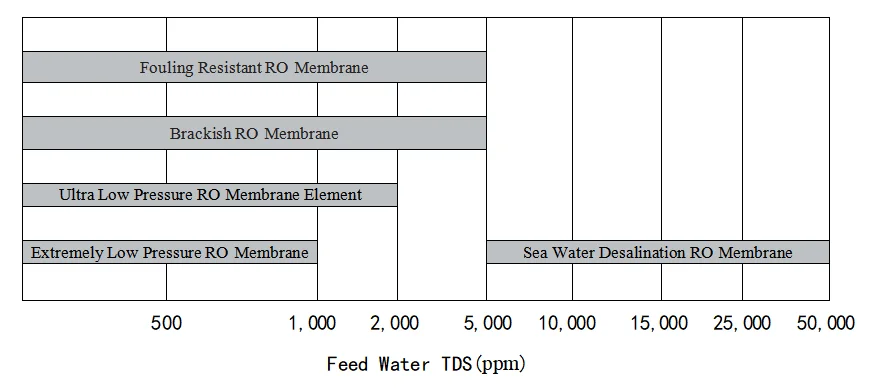

Reverse Osmosis RO Membrane Selecting Guide

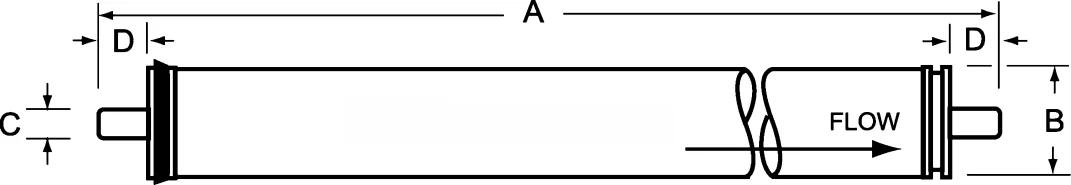

Reverse Osmosis RO Membrane Dimension

2521 2540 4021 4040 Element:

|

Model |

A/mm(inch) |

B/mm(inch) |

C/mm(inch) |

D/mm(inch) |

|

4021 |

533.4 (21) |

99.7 (3.9) |

19.1 (0.75) |

26.7 (1.05) |

|

4040 |

1016.0 (40) |

99.7 (3.9) |

19.1 (0.75) |

26.7 (1.05) |

|

2521 |

533.4 (21) |

61 (2.4) |

19.1 (0.75) |

30.2 (1.19) |

|

2540 |

1016.0 (40) |

61 (2.4) |

19.1 (0.75) |

30.2 (1.19) |

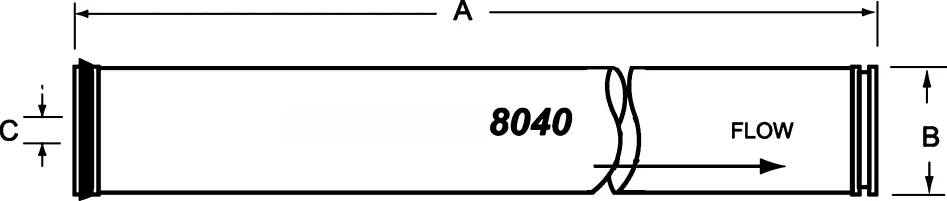

8040 Element:

|

Model |

A/mm(inch) |

B/mm(inch) |

C/mm(inch) |

|

8040 |

1016 (40) |

201 (7.9) |

29 (1.125) |

Reverse Osmosis Membrane Elements Technical Data

XLP Series Membrane Elements

XLP series of membrane elements are made of Polyamide composite membrane materials, which can achieve the desired permeate water and high desalination rate under extremely low pressure operation conditions. The operating pressure is 2/3 of the ULP conventional composite membrane pressure, and the desalination rate can reach 98%. It can improve economic benefits, including reducing the investment cost of related pumps, pipelines, containers and other equipment as well as the operation cost of the whole reverse osmosis system.

XLP series of membrane elements is suitable for desalination treatment of surface water, groundwater, tap water and municipal water with salt content less than 1000 ppm. It is mainly used in various fields of industry, such as pure water, boiler recharge water, food processing and pharmaceutical manufacturing.

XLP series of membrane elements performance

|

Model |

Active Membrane ft2(m2) |

Average Permeate GPD(m3/d) |

Stable Rejection |

Min. Rejection |

|

HC-XLP-2521 |

16(1.5) |

450(1.7) |

98.0 |

97.5 |

|

HC-XLP-2540 |

33(3.0) |

900(3.4) |

98.0 |

97.5 |

|

HC-XLP-4021 |

42(3.9) |

1300(4.9) |

98.0 |

97.5 |

|

HC-XLP-4040 |

85(7.9) |

2600(9.8) |

98.0 |

97.5 |

|

HC-XLP-8040 |

400(37.2) |

12000(45.4) |

98.0 |

97.5 |

|

HC-XLP-8040-440 |

440(40.9) |

13200(49.9) |

98.0 |

97.5 |

XLP series of membrane elements Testing Conditions:

Testing Pressure:100 psi (0.69MPa)

Temperature of Testing Solution:25 ℃

Concentration of Testing Solution (NaCl):500ppm

pH Value of Testing Solution:7.5

Recovery Rate of Single Element:15%

XLP series of membrane elements Operation Limits & Conditions:

Max.Working Pressure:600psi(4.14MPa)

Max.Feed Water Flow:75gpm(17 m3/h) for 8040; 16gpm(3.6 m3/h) for 4040,4021; 6.0gpm(1.4 m3/h) for 2521,2540

Max.Feed Water Temperature: 45℃

Max.Mn: 0.1mg/L

Max.Fe: 0.05mg/L

Max.Turbidity NTU: 1.0

Max.Feed Water SDI15: 5

Max.Feed Water COD: 15ppm

Max.Feed Water BOD: 10ppm

Max.Feed Water TOC: 3ppm

Residual Chlorine Concentration of Feed Water: <0.1ppm

pH Range of Feed Water During Continuous Operation: 3~10

Max.Pressure Drop of Single Element: 15psi(0.1MPa) for 8040,4040,2540; 10psi(0.07MPa) for 2521,4021

ULP Series Membrane Elements

ULP series of membrane elements are made of Polyamide composite membrane materials, which can achieve the desired permeate water and high desalination rate under ultra-low/extreme-low pressure operation conditions. The operating pressure is 2/3 of the BW conventional composite membrane pressure, and the desalination rate can reach 99.3%. It can improve economic benefits, including reducing the investment cost of related pumps, pipelines, containers and other equipment as well as the operation cost of the whole reverse osmosis system.

ULP series of membrane elements is suitable for desalination treatment of surface water, groundwater, tap water and municipal water with salt content less than 2000 ppm. It is mainly used in various fields of industry, such as pure water, boiler recharge water, food processing and pharmaceutical manufacturing.

ULP series of membrane elements performance

|

Model |

Active Membrane ft2(m2) |

Average Permeate GPD(m3/d) |

Stable Rejection |

Min. Rejection |

|

HC-ULP-2521 |

16(1.5) |

400(1.5) |

99.5 |

99.3 |

|

HC-ULP-2540 |

33(3.0) |

800(3.0) |

99.5 |

99.3 |

|

HC-ULP-4021 |

42(3.9) |

1100(4.2) |

99.5 |

99.3 |

|

HC-ULP1-4040 |

85(7.9) |

3100(11.7) |

99.0 |

98.5 |

|

HC-ULP2-4040 |

85(7.9) |

2700(10.2) |

99.3 |

99.0 |

|

HC-ULP3-4040 |

85(7.9) |

2200(8.3) |

99.5 |

99.3 |

|

HC-ULP1-8040 |

400(37.2) |

14000(53) |

99.0 |

98.5 |

|

HC-ULP2-8040 |

400(37.2) |

12000(45.4) |

99.3 |

99.0 |

|

HC-ULP3-8040 |

400(37.2) |

10500(39.7) |

99.5 |

99.3 |

|

HC-ULP3-8040-440 |

440(40.9) |

12000(45.4) |

99.5 |

99.3 |

ULP series of membrane elements Testing Conditions:

Testing Pressure:150 psi (1.03MPa)

Temperature of Testing Solution:25 ℃

Concentration of Testing Solution (NaCl):1500ppm

pH Value of Testing Solution:7.5

Recovery Rate of Single Element:15%

ULP series of membrane elements Operation Limits & Conditions:

Max.Working Pressure:600psi(4.14MPa)

Max.Feed Water Flow:75gpm(17 m3/h) for 8040; 16gpm(3.6 m3/h) for 4040,4021; 6.0gpm(1.4 m3/h) for 2521,2540

Max.Feed Water Temperature: 45℃

Max.Mn: 0.1mg/L

Max.Fe: 0.05mg/L

Max.Turbidity NTU: 1.0

Max.Feed Water SDI15: 5

Max.Feed Water COD: 15ppm

Max.Feed Water BOD: 10ppm

Max.Feed Water TOC: 3ppm

Residual Chlorine Concentration of Feed Water: <0.1ppm

pH Range of Feed Water During Continuous Operation: 3~10

Max.Pressure Drop of Single Element: 15psi(0.1MPa) for 8040,4040,2540; 10psi(0.07MPa) for 2521,4021

BW Series FR Series Membrane Elements

BW series is an aromatic polyamide composite membrane element for desalination of brackish water. It has the characteristics of high water production and good desalination performance. In addition, it has high performance of removing soluble salts, TOC and SiO2, and is especially suitable for the making of high purified water in the electronics and power industries.

It is suitable for desalination treatment of surface water, groundwater, tap water and municipal water with salt content less than 5,000 ppm. It is mainly used for industrial pure water of various scales, boiler feed water of power plants and other industrial water. It can also be used for the treatment of brackish water applications such as high concentration saline waste water and beverage water manufacturing.

FR series, the surface of this membrane was treated by special technology, which changed the electric charge and smoothness of the membrane surface, increased the hydrophilicity of the membrane surface, thus reducing the contamination of pollutants and microorganisms on the membrane surface, and achieving the purpose of reducing the contamination of membrane components and prolonging the service life.

BW series FR series of membrane elements performance:

|

Model |

Active Membrane ft2(m2) |

Average Permeate GPD(m3/d) |

Stable Rejection |

Min. Rejection |

|

HC-BW-2521 |

16(1.5) |

400(1.5) |

99.7 |

99.5 |

|

HC-BW-2540 |

33(3.0) |

800(3.0) |

99.7 |

99.5 |

|

HC-BW-4021 |

42(3.9) |

1100(4.2) |

99.7 |

99.5 |

|

HC-BW-4040 |

85(7.9) |

2400(9.1) |

99.7 |

99.5 |

|

HC-BW-8040 |

400(37.2) |

10500(39.7) |

99.7 |

99.5 |

|

HC-BW-8040-440 |

440(40.9) |

12000(45.4) |

99.7 |

99.5 |

|

HC-FR-4040 |

400(37.2) |

2400(9.1) |

99.7 |

99.5 |

|

HC-FR-8040 |

440(40.9) |

10500(39.7) |

99.7 |

99.5 |

BW series FR series of membrane elements Testing Conditions:

Testing Pressure:225 psi (1.5MPa)

Temperature of Testing Solution:25 ℃

Concentration of Testing Solution (NaCl):2000ppm

pH Value of Testing Solution:7.5

Recovery Rate of Single Element:15%

BW series FR series of membrane elements Operation Limits & Conditions:

Max.Working Pressure:600psi(4.14MPa)

Max.Feed Water Flow:75gpm(17 m3/h) for 8040; 16gpm(3.6 m3/h) for 4040,4021; 6.0gpm(1.4 m3/h) for 2521,2540

Max.Feed Water Temperature: 45℃

Max.Mn: 0.1mg/L

Max.Fe: 0.05mg/L

Max.Turbidity NTU: 1.0

Max.Feed Water SDI15: 5

Max.Feed Water COD: 15ppm

Max.Feed Water BOD: 10ppm

Max.Feed Water TOC: 3ppm

Residual Chlorine Concentration of Feed Water: <0.1ppm

pH Range of Feed Water During Continuous Operation: 3~10

Max.Pressure Drop of Single Element: 15psi(0.1MPa) for 8040,4040,2540; 10psi(0.07MPa) for 2521,4021

Note:

1.For the recommended design scope, please refer to the latest version of the technical manual, design guide, or consult with membrane technology experts. If the user does not strictly follow the operating conditions provided by the sample, Tianjin Justin Technology Co., Ltd will not bear all the consequences arising therefrom.

2.The average water yield listed in the table shows that the error of water yield of single membrane element in series is within (+10%). The difference between the minimum water yield and the nominal value of other series of single membrane elements is not more than 20% of the nominal value.

3.Wet membrane components are strictly tested before they leave the factory. They are stored in 1.0% sodium bisulfite solution. Then they are packed in vacuum and packed in cardboard boxes. The safe storage temperature of wet membrane components is 4-45℃.

4.RO production water to be discharged in the first hour of operation.

5.During storage and operation, it is prohibited to add any chemicals that affect membrane components. In case of violating the use of such chemicals, Tianjin Justin Technology Co., Ltd will not bear all the consequences arising therefrom.

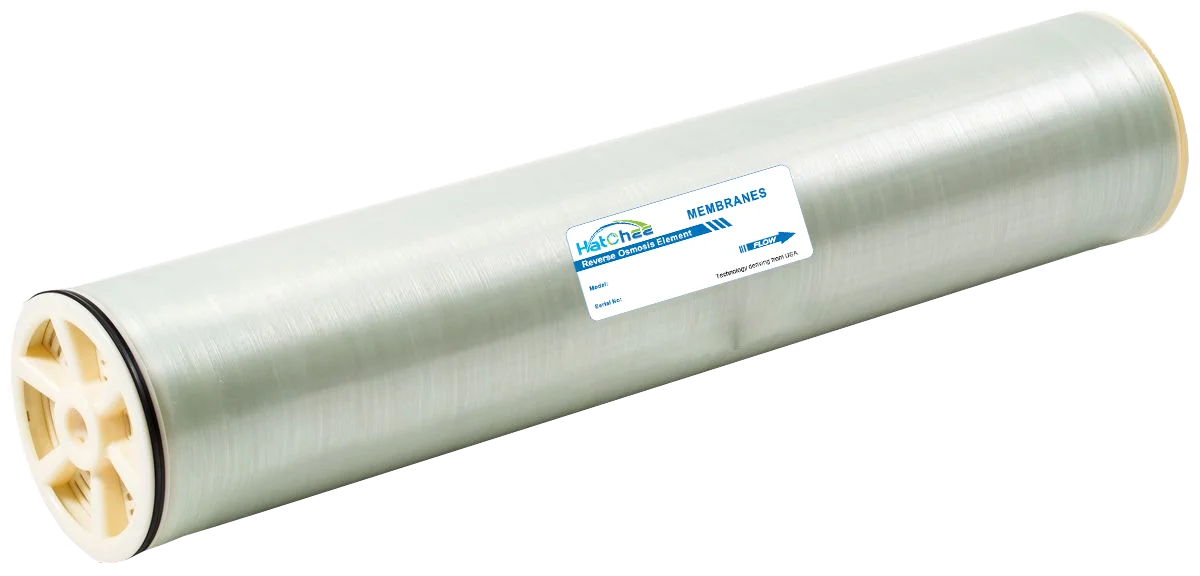

Product Show

Packaging