Product

联系信息

Spacer Tube RO/NF STRO / STNF

STRO/STNF Membrane Introduction

With the development of membrane technology industry, there are differentiated requirements to the performance of the membrane products, such as lower feed quality requirements, higher pressure to improve concentration ratio, longer cleaning cycle and service life. As a result, the open channel type with high pressure membrane arises at the historic moment.

> Used for sea water desalination and waste water treatment.

> Spacer tube (ST) module is high strength design, from 70bar up to 120 bar operating pressure.

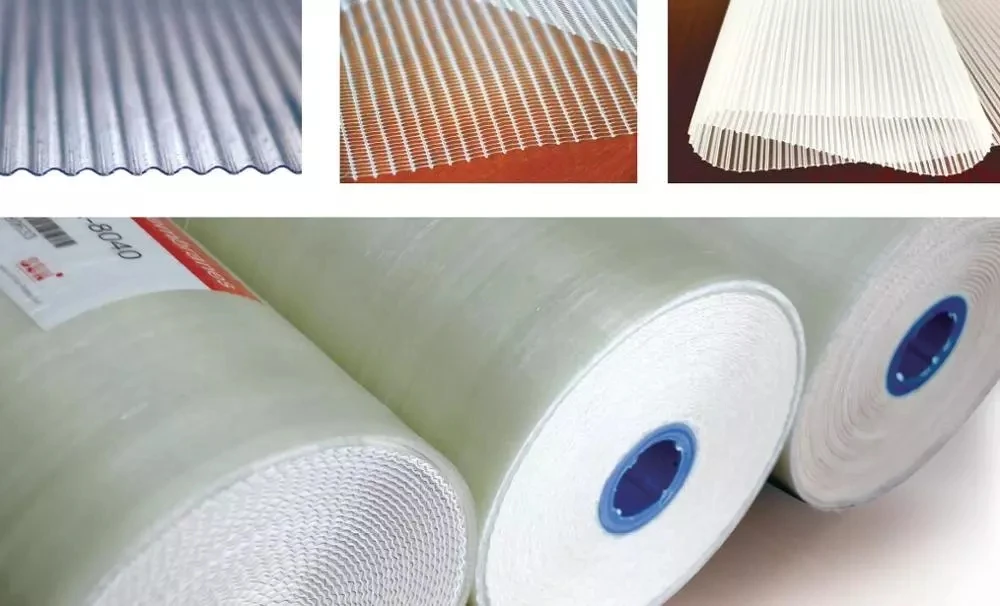

> Open feed spacer with low flow resistance and concentration polarization.

> Spiral wound structure with more membrane area.

Features

High strength design, up to 120 bar operating pressure

Open feed spacer with low flow resistance and concentration polarization

Spiral wound structure with more membrane area

More options for feed spacer

Applications

Industrial wastewater

High salts wastewater

Spiral wound RO/NF concentrates

Open feed spacers

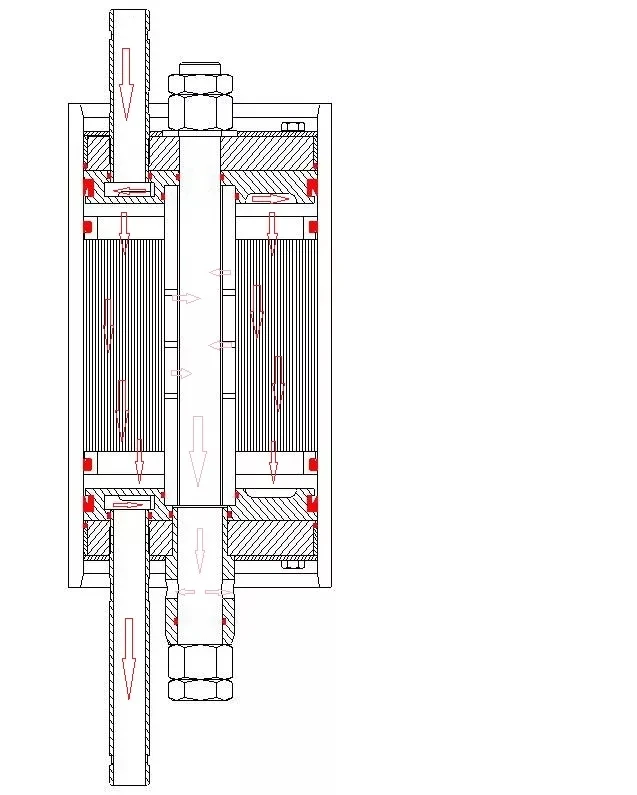

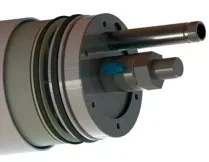

STRO/STNF module

STRO/STNF membrane

High pressure vessel

SUS center link

Inlet and outlet pipe and accessories

Comparison of STRO/STNF Membrane and conventional RO/NF Membrane

Identical

High membrane area

Integrated design

Cross flow filtration

Difference

SUS center link with high strength and stability

Uniform internal water distribution structure

Reduced impact of the membrane module flow, higher cross-flow

Open feed channel

STRO/STNF Membrane Specifications

|

Type |

STRO |

STNF |

|

|

Model |

STRO1-8035 |

STRO5-8042 |

STNF2-8042 |

|

Membrane type |

RO1 |

RO5 |

NF2 |

|

Membrane materia |

Composite Polyamide |

||

|

Membrane effective area (m2) |

25 |

27 |

27 |

|

Element configuration * |

Spiral, fierglass, brine seal |

||

|

Feed flux range (m3/h) |

5.5-12 |

5.5-12 |

|

|

Recommended feed flux (m3/h) |

10 |

10 |

|

|

Stable permeate flux ** (m3/d) |

24 |

18 |

25 |

|

Stable salt rejection **(%) |

98.5 |

99.5 |

98 |

|

Min. salt rejection (%) |

97.5 |

99 |

96 |

|

Feed spacer |

Special open channel |

||

|

Max. TMP (bar) |

0.7 |

0.7 |

|

|

Max. operation pressure (bar) |

120 |

90 |

|

|

Max. operation temperature (℃) |

40 |

40 |

|

|

Feed (SDI) |

≤ 6.5 |

≤ 6.5 |

|

|

pH (continuous) |

3-11 |

3-11 |

|

|

pH (cleaning) |

2-12 |

2-12 |

|

|

Chlorine tolerance (ppm) |

≤ 0.1 |

≤ 0.1 |

|

Salt seal installed on the end of the flow, low pressure side / permeate side.

Stable flux, salt rejection based on the following test conditions:

RO1: 2000mg/l NaCl , pressure 15.5bar, recycle rate 15% , temperature 25℃, pH=8.

RO5:32,000 mg/l NaCl , pressure 55bar, recycle rate 8%, temperature 25℃, pH=8.

NF2:2000 mg/l MgSO4, pressure 7barr, recycle rate 15% , temperature 25℃, pH=8.

Note: We can provide any flat sheet membrane to make ST module, for example: STRO4-8035, STRO5-8035, STRO1-8042, STNF1-8042, etc.

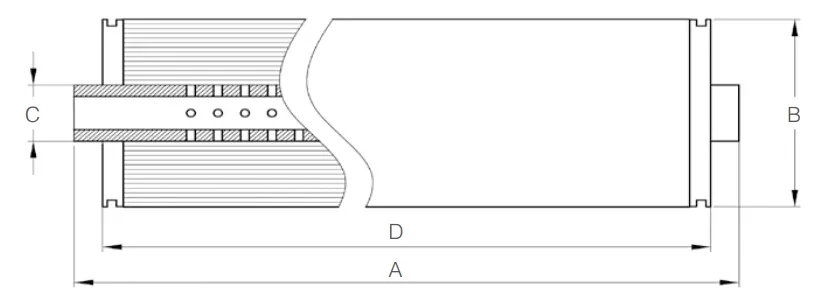

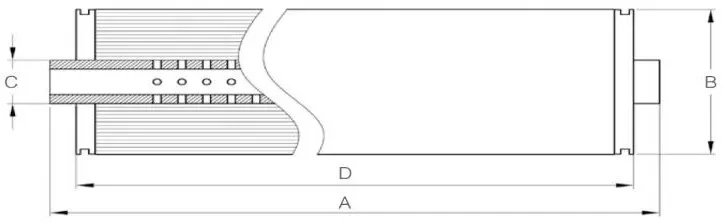

|

Model |

8035 |

8042 |

|

Element total length (A) |

890mm |

1070mm |

|

Element diameter (B) |

200mm |

200mm |

|

Center tube outer diameter (C) |

60.2mm |

60.2mm |

|

Membrane body length (D) |

838mm |

1016mm |

STRO Membrane Element

Features:

Spiral High Pressure, High Rejection, Open Spacer.

Applications:

Landfill Leachate & Other High TSS Water.

STRO Membrane Element Specification

|

Model |

STRO1-8035 |

STRO4-8035 |

STRO5-8035 |

STNF2-8035 |

|

Membrane Sheet Type |

RO1 |

RO4 |

RO5 |

NF2 |

|

Membrane Material |

Polyamide |

|||

|

Effective Membrane Area |

25m2 (269ft2) |

|||

|

Construction * |

Spiral Wound Element with GRP Outerwrap,Brine Seal |

|||

|

Feed Flow Rate Range |

5.5-12m3/h |

|||

|

Permeate Flow Rate |

24m3/d |

9.5m3/d |

16m3/d |

22m3/d |

|

Nominal Rejection |

98.5% |

99.6% |

99.5% |

98.0% |

|

Minimum Rejection |

97.5% |

99.0% |

99.0% |

96.0% |

|

Feed Spacer |

Special open type |

|||

|

Element Dry Weight |

18kgs |

|||

|

Max. Element Pressure Drop |

0.7bar |

|||

|

Max. Operation Pressure |

90bar |

|||

|

Max. Operation Temperature |

40℃ |

|||

|

pH continuous |

3-11 |

|||

|

pH CIP |

2-12 |

|||

|

Chlorine Tolerance |

≤0.1ppm |

|||

Brine seal to be installed in flow direction on the low pressure side/element outlet side.

Performance specifications shown are nominal values. Individual module permeate flow rate may vary based on inlet water condition. RO1 test condition: 2,000mg/l NaCl solution at 15.5bar applied pressure, 15% recovery, 25℃, pH=8; RO4 test condition: 32,000mg/l NaCl solution at 55.2bar applied pressure, 15% recovery, 25℃, pH=8.

Please note flow rate for different water condition may vary.

STRO Membrane Element Dimensions

|

Model |

STRO-8035 |

|

Element Total Length ("A") |

890mm |

|

Element Diameter ("B") |

200mm |

|

Permeate Tube Outer Diameter ("C") |

60.2mm |

|

Element Total Length ("D") |

838mm |

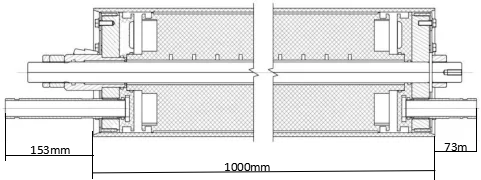

STRO Membrane Module Dimensions

STRO Membrane Element

Features:

Spiral High Pressure, High Rejection, Open Spacer.

Applications:

Landfill Leachate & Other High TSS Water.

STRO Membrane Element Specification

|

Model |

STRO1-8042 |

STRO4-8042 |

STRO5-8042 |

STNF2-8042 |

|

Membrane Sheet Type |

RO1 |

RO4 |

RO5 |

NF2 |

|

Membrane Material |

Polyamide |

|||

|

Effective Membrane Area |

27m2 (290.52ft2) |

|||

|

Construction * |

Spiral Wound Element with GRP Outerwrap,Brine Seal |

|||

|

Applications |

High TSS water |

|||

|

Feed Flow Rate Range |

5.5-12m3/h |

|||

|

Permeate Flow Rate |

30m3/d |

13m3/d |

18m3/d |

25m3/d |

|

Nominal Rejection ** |

98.5% |

99.6% |

99.5% |

98.0% |

|

Minimum Rejection |

97.5% |

99.0% |

99.0% |

96.0% |

|

Feed Spacer |

Special open type |

|||

|

Element Dry Weight |

20kgs |

|||

|

Max. Element Pressure Drop |

0.7bar |

|||

|

Max. Operation Pressure |

75bar |

|||

|

Max. Operation Temperature |

40℃ |

|||

|

pH continuous |

3-11 |

|||

|

pH CIP |

2-12 |

|||

|

Chlorine Tolerance |

≤0.1ppm |

|||

Brine seal to be installed in flow direction on the low pressure side/element outlet side.

Performance specifications shown are nominal values. Individual module permeate flow rate may vary based on inlet water condition. RO1 test condition: 2,000mg/l NaCl solution at 15.5bar applied pressure, 15% recovery

25℃, pH=8; RO4 test condition: 32,000mg/l NaCl solution at 55.2bar applied pressure, 15% recovery, 25℃, pH=8. Please note flow rate for different water condition may vary.

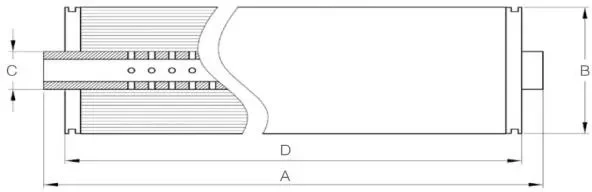

STRO Membrane Element Dimensions

|

Model |

STRO-8042 |

|

Element Total Length ("A") |

1070mm |

|

Element Diameter ("B") |

200mm |

|

Permeate Tube Outer Diameter ("C") |

60.2mm |

|

Element Total Length ("D") |

1016mm |

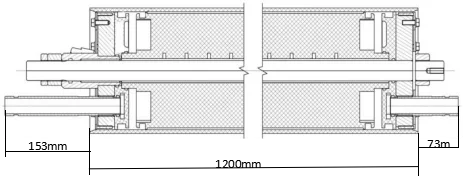

STRO Membrane Module Dimensions

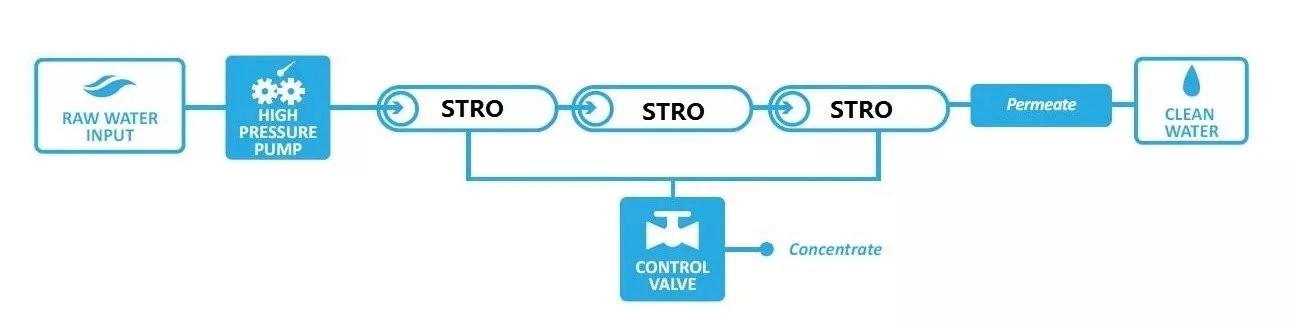

How STRO membrane works

Product Show