Product

联系信息

PRODUCT DESCRIPTION

KDF (Kinetic Degradation Fluxion) media consist of high- copper-zinc granules that are used in pre-treatment for the purposes of reducing chlorine and soluble heavy metals. These filters can also be utilized in primary treatment and wastewater treatment for removing the same contaminants, including bacteria, lead, fungi, magnesium, bacteria, converting them into unthreatening elements. This process helps preserve the life of the system and prevents maintenance issues. The Kdf 85 water filter is also specifically designed to eliminate hydrogen sulfide gas.

KDF 55 water filters are capable of removing up to 99% of chlorine and about 98% of water soluble ions such as copper, lead, nickel, mercury, and related dissolved metals. The KDF 85 water filter is more effective in targeting and taking out high percentages of iron from the water supply. There is a back washing process which eradicates build-up of the copper, sulfur from the media bed. These features make the KDF media very suitable filters for showers and kitchens.

KDF Process Media are highpurity copper-zinc granules that reduce contaminants in water using oxidation/reduction (redox) reaction. KDF 55 process medium is an effective chlorine removal agent used in point-of-entry (POE) treatment of municipal water supplies. KDF 85 process medium is an effective iron (ferrous) and hydrogen sulfide (H2S) removal agent that may be used alone or to protect existing water filtration/purification technologies in POE treatment of groundwater supplies.

These unique, innovative and environmentally responsible media consist of high purity copper-zinc granules that use redox (the exchange of electrons) in patented products to effectively reduce/remove chlorine, iron, hydrogen sulfide, heavy metals, and control microorganisms in potable water without the use of chemicals. What’s more, KDF 55 and 85 media are highly efficient and tank size requirements are modest for more economical system engineering and installation. This bulletin describes the proper use of KDF media in residential (whole house), commercial, institutional, and light industrial buildings and facilities with potable

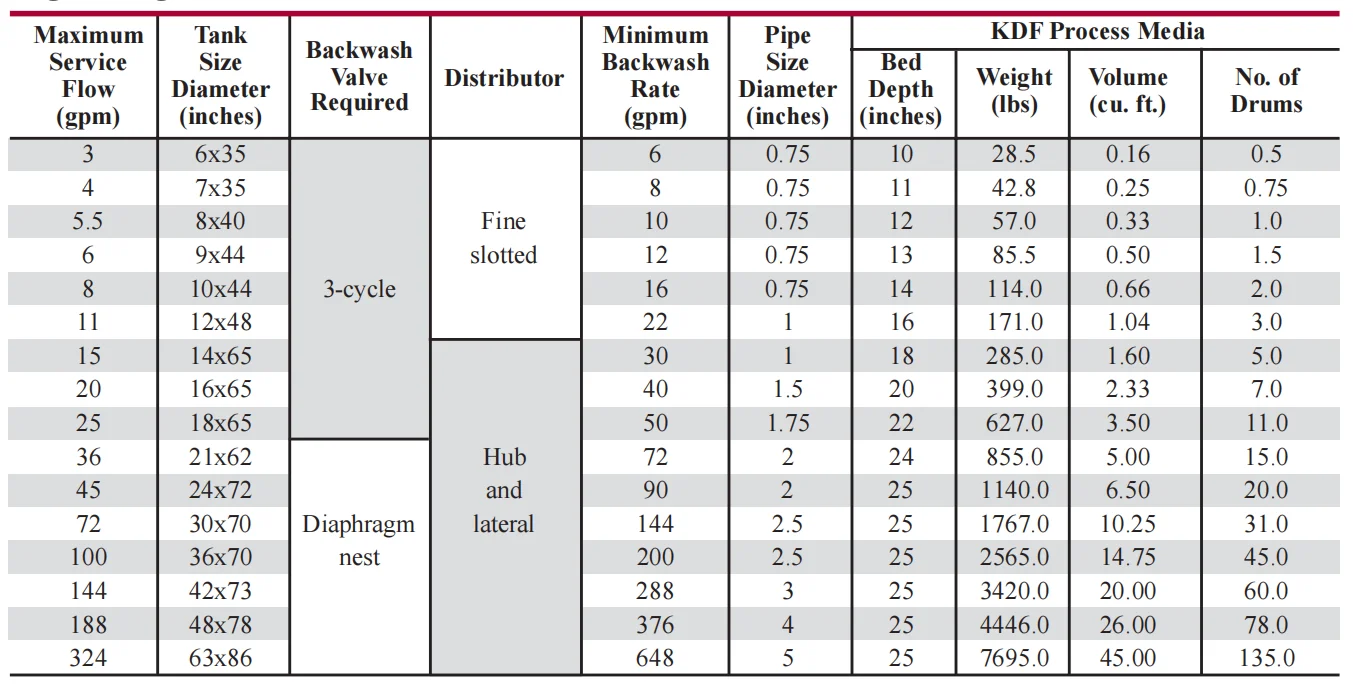

water service flows in a range from 3 to 324 gallons per minute with maximum chlorine, iron, and H2S concentrations of 5 ppm/mgl.

Medium Requirements and System Sizing

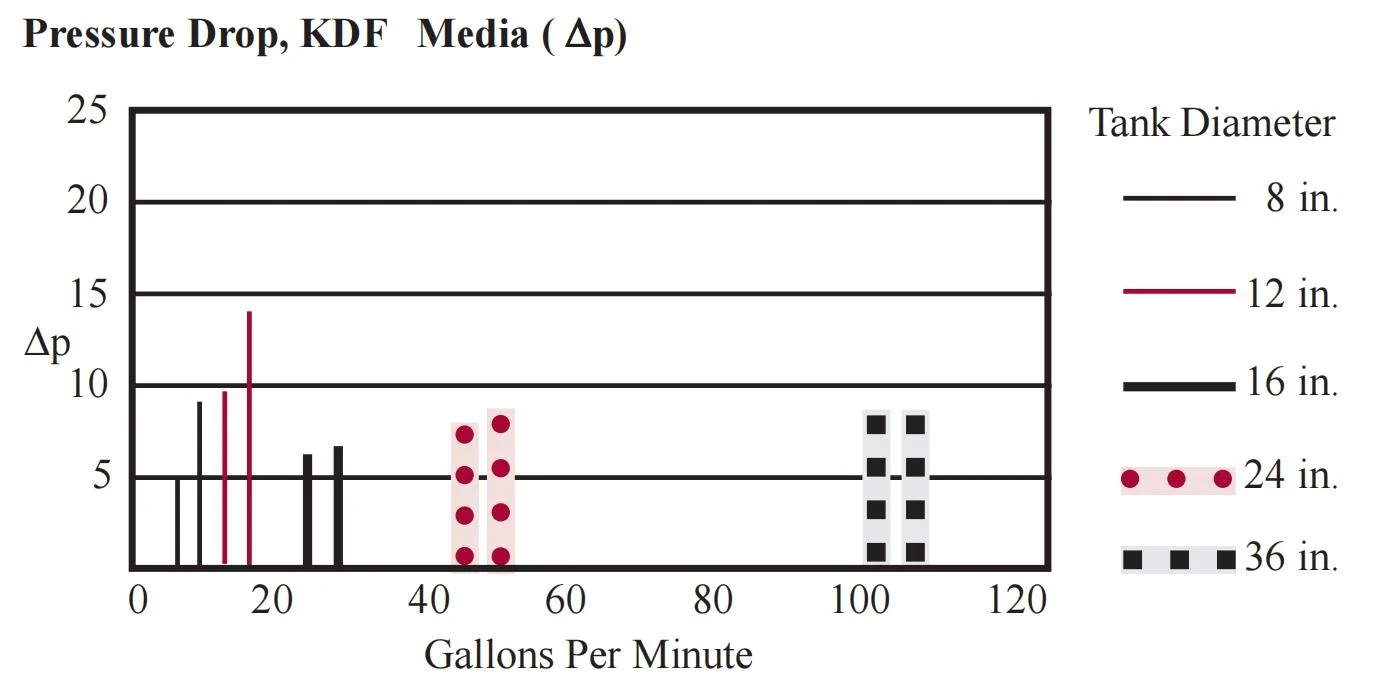

Easily the most critical aspect of pressure filter performance is the relationship of flow rate to surface of KDF media. Inaccurate sizing is the most common reason for trouble in filter systems. The nominal flow rate in the service cycle depends on surface area available. For most types of filter media, the service flow rate must not exceed five gallons per minute (gpm) per square foot of surface area, with at least a 30-inch filter bed depth.

Service flow rates with KDF Process Media, however, may be calculated at 15 gpm per square foot of surface area (0.104 gpm per square inch).

This is three times the effective flow rate of other filter media.

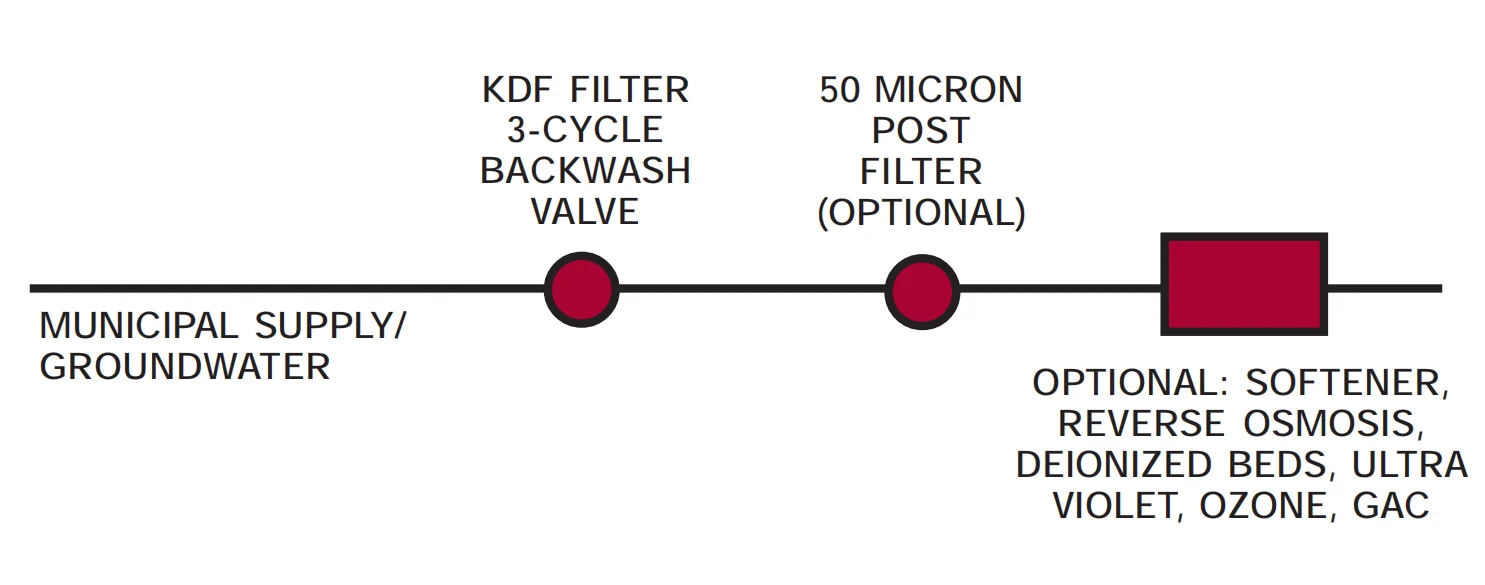

Backwashing KDF Process Media

In electrochemical reduction processes, surface products are formed when KDF media are used in point-of-entry (POE) water treatment systems. These byproducts, along with any calcium and magnesium precipitate, must be periodically backwashed. For backwash rates of 3 to 25 gpm, use a high quality 3-cycle backwash valve (service, backwash, purge). One with a high-flow backwash mode is best. For 36 to 324 gpm, use a diaphragm nest valve.

Remember to remove any backwash flow restrictors. Select a distributor based on backwash flow rate. For 3 to 11 gpm, use a fine slotted distributor and for 15 to 324 gpm, use a hub and lateral distributor (#8 garnet underbedding is recommended). Time the backwash cycle for ten minutes and purge for three minutes. Backwash at least three times per week, more frequently if necessary, depending upon the quality of the water supply. If more backwashing is required, repeat the entire cycle. Backwash flow rates are a function of backwash water temperature; type, size and density of media; and the specific design of the pressure filter. KDF Process Media have a density of 171 pounds per cubic foot, which makes it a very high density medium requiring a backwash flow rate of twice the service flow.

KDF media require 30 gallons per minute per square foot of bed surface area. Very cold water requires somewhat lower backwash rates and warmer water requires higher rates. Do not restrict pipe size to the drain.

Note: If backwashing procedures are not properly followed, KDF Process Media may become fouled. For proper cleaning techniques, contact KDF’s Technical Department.

MODELS

KDF-55 Filter Media, 4 Pounds

Sold sold in 4 pound container

KDF-55 process medium is an effective chlorine removal, heavy metal removal , and a bacteriostatic agent used in point of entry treatment of municipal water supplies. This unique, innovative and environmentally responsible medium consists of high purity copper-zinc granules that use redox (the exchange of electrons) in patented products to effectively reduce/remove chlorine and heavy metals and control microorganisms in potable water.

The most critical aspect of pressure filter performance is the relationship of flow rate to surface of KDF-55 process medium. Inaccurate sizing is the most common reason for the trouble in filter systems. The nominal flow rate in the service cycle depends on surface area available. Service flow rates with KDF-55 process medium, however, may be calculated at 15 gpm per square foot of surface area. This is three times the effective flow rate of other filter media.

KDF-85 Filter Media, 4 Pounds

Sold sold in 4 pound container

KDF-85 process medium is an effective iron (ferrous) and hydrogen sulfide (H2S) removal agent that may be used alone or to protect existing water filtration/purification technologies in point-of-entry treatment of groundwater supplies. This unique, innovative and environmentally responsible medium consists of high purity copper-zinc granules that use redox (the exchange of electrons) in patented products to effectively reduce/remove iron and hydrogen sulfide and heavy metals and control microorganisms in potable water. KDF-83 medium permits the removal of iron and H2S without the use of chemicals.

The most critical aspect of pressure filter performance is the relationship of flow rate to surface of KDF-85 process medium. Inaccurate sizing is the most common reason for the trouble in filter systems. The nominal flow rate in the service cycle depends on surface area available. Service flow rates with KDF-85 process medium, however, may be calculated at 15 gpm per square foot of surface area. This is three times the effective flow rate of other filter media.

|

KDF Media POE Recommended Operating Conditions(use 3-cycle valve) |

|

|

Service flow |

15 gpm/sq. ft. |

|

Backwash for 10 min. @ |

30 gpm /sq. ft. |

|

Purge/rinse for 3 min. @ |

maximum |

|

Bed expansion, backwash |

10 to 15% |

|

Free board |

20% |

|

Minimum bed depth (6" dia.) |

10" |

|

pH range: drinking water |

6.5 to 8.5 |

|

Water temperature, influent |

35°F to 212°F |

|

(Always maintain wetness) |

|

Engineering Guidelines for KDF Media

KDF MEDIA FEATURES:

Effective chlorine removal agent

May be used independently or to protect existing water filtration equipment

Innovative and unique design

Environmentally friendly

Three times the effective flow rate of other filter media

APPLICATIONS

KDF Filtration Media is designed for chlorine removal in point-of-use applications