Product

联系信息

Water Filter Cartridge

1.8 High Flow Filter Cartridge

Description

High Flow Filter Cartridge is single open ended which design for the direction from an inside to outside flow pattern. The large filter area ensure the high dirt holding capacity. The low cost save the number of filter cartridge. Long service life and superior flow rates are the main characteristics. All contaminants can be removed efficiently. Our High flow filter cartridge can be replace for PALL ULTIPLEAT ,CUNO 3M,PARKER MEGAFLOW AND PENTAIR AQUALINE FILTERATION SYSTEMS

Applications

• Pre-filtration of RO, Pre-treatment of sea water desalination

• Bottled water, high Fructose, edible oil, soft drinks

• API, solvents, and water filtration in BioPharm market

• Paints and coatings, Petrochemical, Refineries

• Microelectronics

Specification

Material of Construction

• Media: Pleated glass fiber, Pleated PP

• Support layer: Polypropylene

• End adaptor: Glass fiber reinforced Polypropylene

• Seal Material: Silicone, EDPM, Buna

• Micron Rating: 1μm, 4.5μm, 6μm, 10μm,20μm,40μm,70μm,100μm

• Filtration Area: 20 inch: 660LPM, 40inch: 1300LPM, 60inch: 1900LPM

Dimensions

• Outside diameter: 6" (152mm)

• Length: 20inch(525mm), 40inch(1033mm), 60inch(1541mm)

Recommended Operating Conditions

Maximum Operating Temperature:

• Pleated glass fiber: 121°C

• Pleated PP: 82°C

Ordering

|

Model |

Micron Rating |

Seal |

Length |

|

HF-A Pleated glass fiber HF-B Pleated PP |

10: 1μm 45: 4.5μm 60: 6μm ………. |

E-EPDM N-Buna |

20" 40" 60" |

1.6 Polyester Pleated Filter Cartridge

Description

Polyester(PE) Pleated Filter Cartridge is made of pleated

polyester media. The benefits can be summary:

low pressure drop, increased surface life, excellent

contaminant removal.

Applications

• Rain water, Ro treatment

• Food and beverage

• Paints, coatings and plating solutions

• Acid-base liquid

• Chemicals and organic solvents

Specification

Material of Construction

• Filter Media: Polyester, Cellulose,pp

• Core: Polypropylene

• End cap : PU/plastisol

Micron Rating: 1µm ,3µm ,5µm, 10µm,20µm,50µm

Dimensions

• Inside diameter: 28mm

• Outside diameter: 68mm or 115mm

• Length: 9 3/4’’,97/8’’10", 20", 30", 40"

Recommended Operating Conditions

|

Operating Temperature |

Filtration Life |

Max.Operating Pressure |

Max.Flow |

|

4°C - 40°C |

10” Standard: 3-6 months/2500G 10” Big Blue: 4-6 months/5500G Depends on water quality and level of contaminants |

60 psi |

10” Standard: 2.5GPM 10” Big Blue: 5GPM |

Ordering

|

Model |

Netting |

Micron Rating |

Dimension |

Length |

|

PLP |

P:polyethylene N:none |

1: 1μm 3: 3μm 5: 5μm 10: 10μm ...... ...... 100: 100μm |

A- ID28mm OD68mm B- ID28mm OD115mm

|

10" 20" 30" 40" |

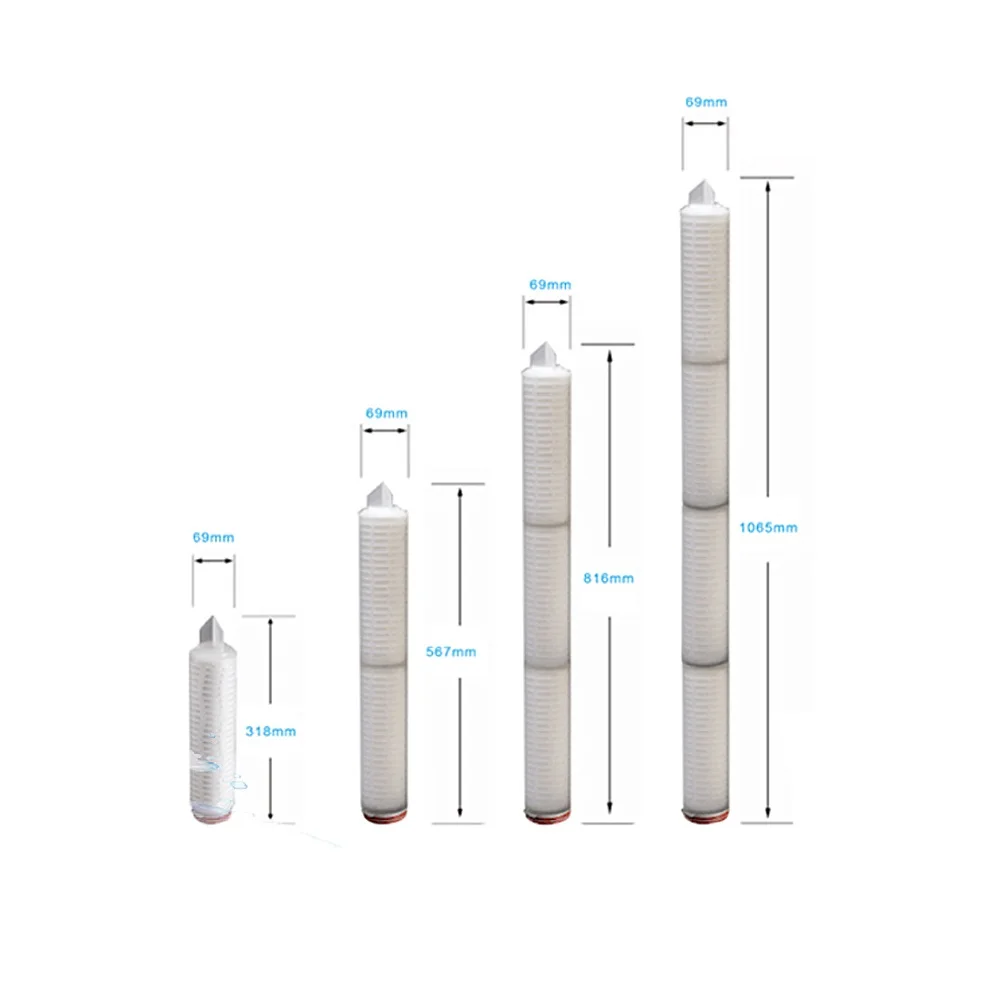

1.7 Pleated Filter Cartridge

Description

Pleated Filter Cartridge is made of Polypropylene(PP), Polyvinylidene Fluoride(PVDF), Polyether Sulphore(PES), Nylon-6(N6) or Poly Tetra Fluoroethylene(PTFE). It has a big surface area and good dirt-holding capacity. The body is sweating soldered and no binder or adhesive added. It is widely applied in the production or pure water, medicine, etc.

Applications

• Pre-filtration for RO system

• Solvents, selected acids & lyes, chemical industry

• Semiconductor, Electronic industry ultra-pure water system

• Food and beverage

• Oil and Gas industry

• Pharmaceutics

• Paints, coatings and plating solutions

• Wine, liquor and other alcohol drinks

Specification

Material of Construction

• Filter Media: Polypropylene(PP), Polyvinylidene Fluoride(PVDF), Polyether Sulphore(PES), Nylon-6(N6) or

Poly Tetra Fluoroethylene(PTFE)

• Support : Polypropylene • Core / Cage / End adaptor: Polypropylene

• Sealing Technology: Thermal bonding No Adhesives

• Seal Material: Silicone, EDPM, Buna, , Teflon, E-FKM

• Filtration Area: 0.5-0.7m2 each 10" length

Micron Rating: 0.1µm, 0.22µm, 0.45µm, 0.65µm,0.80µm, 1µm, 3µm, 5µm, 10µm, 20µm, 50µm

Dimensions:

• Outside diameter: 2.7” (69mm)

• Length: 5", 10", 20", 30", 40"

Recommended Operating Conditions

|

Material |

Operating Temperature |

Filtration Life |

Max.Sterilizing Temperature |

|

PP |

4°C - 80°C |

10” Standard: 3-6 months/2500G Depends on water quality and level of contaminants |

5times, 20 Min @121°C |

|

PVDF |

4°C - 90°C |

100times, 30 Min @121°C |

|

|

PES |

4°C - 85°C |

20times, 30 Min @121°C |

|

|

Nylon-6 |

4°C - 60°C |

20times, 30 Min @121°C |

|

|

Hydrophilic PTFE |

4°C - 95°C |

100times, 30 Min @121°C |

|

|

Hydrophobic PTFE |

4°C - 95°C |

100times, 30 Min @121°C |

Ordering

|

Model |

Micron Rating |

End Adaptor |

Seal |

Length |

|

PF-A PP PF-B PVDF PF-C PES PF-D Nylon-6 PF-E Hydrophilic PTFE PF-F Hydrophobic PTFE |

010: 0.1μm 022: 0.22μm 045: 0.45μm ........ 10: 1μm 30: 3μm ........ 500: 50μm |

0 - DOE Double open end 1 - 226/Fin 2 - 222/Fin 3 - 222/Flat closed 4 - 226/Flat closed 5 - 215/Flat closed 6 - O-ring insert/Flat closed 7 - The others |

E-EPDM N-Buna S-Silicone V- T-Teflon E-FKM |

5" 10" 20" 30" 40" |